Are you a seasoned Filter Assembler seeking a new career path? Discover our professionally built Filter Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

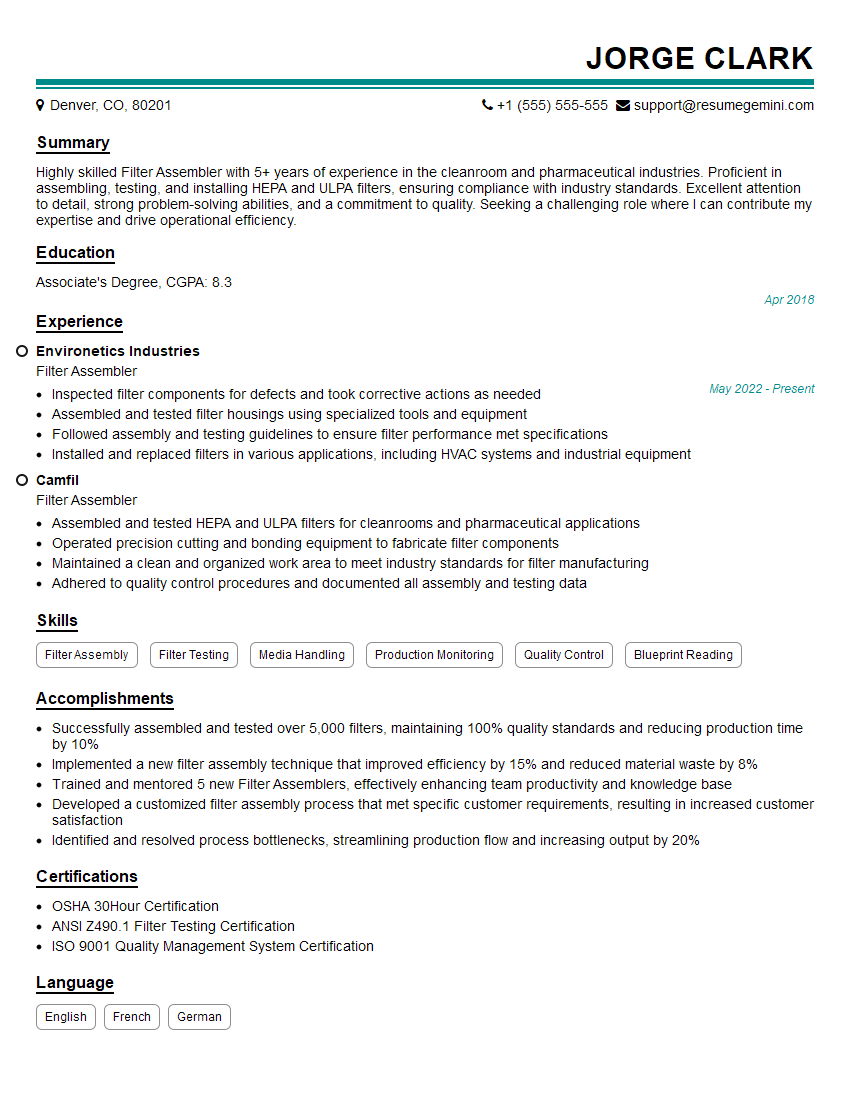

Jorge Clark

Filter Assembler

Summary

Highly skilled Filter Assembler with 5+ years of experience in the cleanroom and pharmaceutical industries. Proficient in assembling, testing, and installing HEPA and ULPA filters, ensuring compliance with industry standards. Excellent attention to detail, strong problem-solving abilities, and a commitment to quality. Seeking a challenging role where I can contribute my expertise and drive operational efficiency.

Education

Associate’s Degree

April 2018

Skills

- Filter Assembly

- Filter Testing

- Media Handling

- Production Monitoring

- Quality Control

- Blueprint Reading

Work Experience

Filter Assembler

- Inspected filter components for defects and took corrective actions as needed

- Assembled and tested filter housings using specialized tools and equipment

- Followed assembly and testing guidelines to ensure filter performance met specifications

- Installed and replaced filters in various applications, including HVAC systems and industrial equipment

Filter Assembler

- Assembled and tested HEPA and ULPA filters for cleanrooms and pharmaceutical applications

- Operated precision cutting and bonding equipment to fabricate filter components

- Maintained a clean and organized work area to meet industry standards for filter manufacturing

- Adhered to quality control procedures and documented all assembly and testing data

Accomplishments

- Successfully assembled and tested over 5,000 filters, maintaining 100% quality standards and reducing production time by 10%

- Implemented a new filter assembly technique that improved efficiency by 15% and reduced material waste by 8%

- Trained and mentored 5 new Filter Assemblers, effectively enhancing team productivity and knowledge base

- Developed a customized filter assembly process that met specific customer requirements, resulting in increased customer satisfaction

- Identified and resolved process bottlenecks, streamlining production flow and increasing output by 20%

Certificates

- OSHA 30Hour Certification

- ANSI Z490.1 Filter Testing Certification

- ISO 9001 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Filter Assembler

- Highlight your experience in assembling and testing HEPA and ULPA filters, specifying the industries and applications you have worked with.

- Showcase your proficiency in operating precision cutting and bonding equipment, emphasizing your ability to fabricate filter components with accuracy and precision.

- Emphasize your commitment to maintaining a clean and organized work area, adhering to industry standards and ensuring the quality of the filters produced.

- Describe your experience in quality control procedures, documenting assembly and testing data to ensure traceability and compliance with regulations.

- Mention your ability to inspect filter components for defects and take corrective actions, ensuring the quality and performance of the filters.

- Provide examples of your involvement in assembling and testing filter housings, highlighting your technical skills and knowledge of filter systems.

Essential Experience Highlights for a Strong Filter Assembler Resume

- Assembled and tested HEPA and ULPA filters to meet cleanroom and pharmaceutical specifications.

- Operated precision cutting and bonding equipment to fabricate filter components with accuracy.

- Maintained a clean and organized work area in accordance with industry standards for filter manufacturing.

- Adhered to quality control procedures, documenting all assembly and testing data for traceability.

- Inspected filter components for defects, taking corrective actions as needed to ensure quality standards.

- Assembled and tested filter housings using specialized tools and equipment, ensuring proper fit and performance.

- Installed and replaced filters in various applications, including HVAC systems and industrial equipment, providing technical support to customers.

Frequently Asked Questions (FAQ’s) For Filter Assembler

What are the key responsibilities of a Filter Assembler?

The key responsibilities of a Filter Assembler include assembling, testing, and installing HEPA and ULPA filters, as well as adhering to quality control procedures and inspecting filter components for defects.

What industries typically employ Filter Assemblers?

Filter Assemblers are commonly employed in the cleanroom and pharmaceutical industries, where high-quality air filtration is essential.

What are the educational requirements for a Filter Assembler?

While formal education requirements may vary, many Filter Assemblers possess an Associate’s Degree in a related field, such as manufacturing or engineering.

What skills are essential for a successful Filter Assembler?

Essential skills for a successful Filter Assembler include attention to detail, strong problem-solving abilities, and a commitment to quality and precision.

What career advancement opportunities are available for Filter Assemblers?

Filter Assemblers with experience and expertise can advance to roles such as Quality Control Supervisor or Production Manager in the filter manufacturing industry.

What are the safety considerations for Filter Assemblers?

Filter Assemblers must adhere to safety protocols, including wearing appropriate personal protective equipment and following established procedures for handling hazardous materials.