Are you a seasoned Final Assembly Inspector seeking a new career path? Discover our professionally built Final Assembly Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

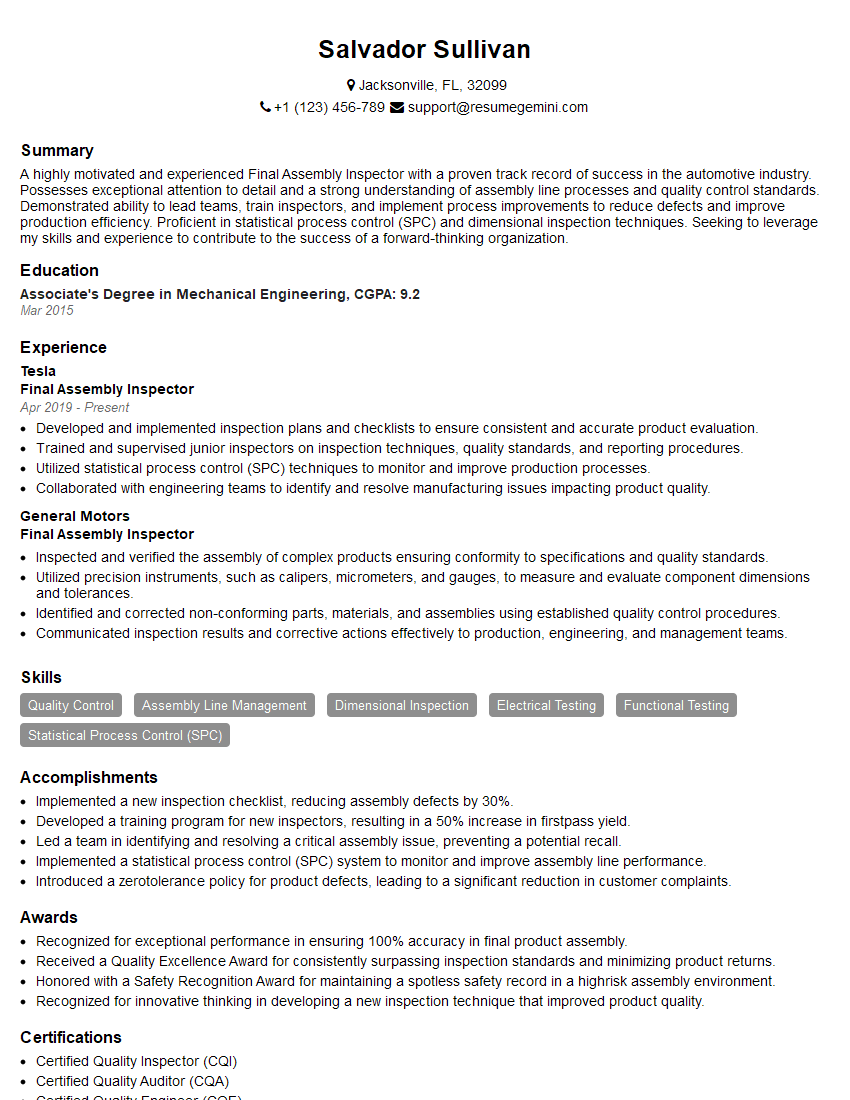

Salvador Sullivan

Final Assembly Inspector

Summary

A highly motivated and experienced Final Assembly Inspector with a proven track record of success in the automotive industry. Possesses exceptional attention to detail and a strong understanding of assembly line processes and quality control standards. Demonstrated ability to lead teams, train inspectors, and implement process improvements to reduce defects and improve production efficiency. Proficient in statistical process control (SPC) and dimensional inspection techniques. Seeking to leverage my skills and experience to contribute to the success of a forward-thinking organization.

Education

Associate’s Degree in Mechanical Engineering

March 2015

Skills

- Quality Control

- Assembly Line Management

- Dimensional Inspection

- Electrical Testing

- Functional Testing

- Statistical Process Control (SPC)

Work Experience

Final Assembly Inspector

- Developed and implemented inspection plans and checklists to ensure consistent and accurate product evaluation.

- Trained and supervised junior inspectors on inspection techniques, quality standards, and reporting procedures.

- Utilized statistical process control (SPC) techniques to monitor and improve production processes.

- Collaborated with engineering teams to identify and resolve manufacturing issues impacting product quality.

Final Assembly Inspector

- Inspected and verified the assembly of complex products ensuring conformity to specifications and quality standards.

- Utilized precision instruments, such as calipers, micrometers, and gauges, to measure and evaluate component dimensions and tolerances.

- Identified and corrected non-conforming parts, materials, and assemblies using established quality control procedures.

- Communicated inspection results and corrective actions effectively to production, engineering, and management teams.

Accomplishments

- Implemented a new inspection checklist, reducing assembly defects by 30%.

- Developed a training program for new inspectors, resulting in a 50% increase in firstpass yield.

- Led a team in identifying and resolving a critical assembly issue, preventing a potential recall.

- Implemented a statistical process control (SPC) system to monitor and improve assembly line performance.

- Introduced a zerotolerance policy for product defects, leading to a significant reduction in customer complaints.

Awards

- Recognized for exceptional performance in ensuring 100% accuracy in final product assembly.

- Received a Quality Excellence Award for consistently surpassing inspection standards and minimizing product returns.

- Honored with a Safety Recognition Award for maintaining a spotless safety record in a highrisk assembly environment.

- Recognized for innovative thinking in developing a new inspection technique that improved product quality.

Certificates

- Certified Quality Inspector (CQI)

- Certified Quality Auditor (CQA)

- Certified Quality Engineer (CQE)

- ASQ Certified Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Final Assembly Inspector

- Highlight your experience in the automotive or manufacturing industry, as well as your specific knowledge of assembly line processes and quality control standards

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Demonstrate your proficiency in statistical process control (SPC) and dimensional inspection techniques.

- Showcase your ability to lead teams, train inspectors, and implement process improvements.

Essential Experience Highlights for a Strong Final Assembly Inspector Resume

- Conduct final inspections of assembled products to ensure adherence to specifications and quality standards.

- Utilize dimensional inspection tools and equipment to verify product dimensions and tolerances.

- Perform electrical and functional testing to assess product functionality and compliance with design requirements.

- Identify and document defects and non-conformities, and initiate corrective actions to resolve issues.

- Review inspection reports and provide feedback to assembly line operators to improve assembly processes.

- Implement and maintain statistical process control (SPC) systems to monitor and analyze production data.

- Collaborate with engineers and quality assurance personnel to address quality issues and implement process improvements.

Frequently Asked Questions (FAQ’s) For Final Assembly Inspector

What are the key skills required for a Final Assembly Inspector?

Key skills include attention to detail, strong understanding of assembly line processes and quality control standards, proficiency in dimensional inspection techniques, knowledge of electrical and functional testing procedures, and analytical skills for data analysis using statistical process control (SPC).

What are the career prospects for a Final Assembly Inspector?

With experience and additional certifications, Final Assembly Inspectors can advance to roles such as Quality Control Inspector, Quality Assurance Manager, or Manufacturing Supervisor.

What is the work environment like for a Final Assembly Inspector?

Final Assembly Inspectors typically work in manufacturing facilities or assembly plants, where they may be exposed to noise, dust, and potential hazards. They often work on assembly lines, performing repetitive tasks, and may need to stand or walk for extended periods.

What are the educational requirements for a Final Assembly Inspector?

While some positions may require only a high school diploma or equivalent, most employers prefer candidates with an Associate’s Degree in Mechanical Engineering, Manufacturing Technology, or a related field.

What certifications are beneficial for a Final Assembly Inspector?

Certifications such as Certified Quality Inspector (CQI) from the American Society for Quality (ASQ) or Certified Manufacturing Technologist (CMfgT) from the Society of Manufacturing Engineers (SME) can enhance credibility and career prospects.

What is the salary range for a Final Assembly Inspector?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Quality Control Inspectors was $43,930 in May 2021. However, salaries can vary based on experience, location, and industry.

What is the job outlook for Final Assembly Inspectors?

The U.S. Bureau of Labor Statistics projects a 6% growth in employment for Quality Control Inspectors from 2021 to 2031, due to increasing demand for quality assurance in manufacturing and production industries.

What are the different industries that employ Final Assembly Inspectors?

Final Assembly Inspectors are employed in various industries, including automotive, aerospace, electronics, and medical device manufacturing.