Are you a seasoned Fireproof Door Maker seeking a new career path? Discover our professionally built Fireproof Door Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

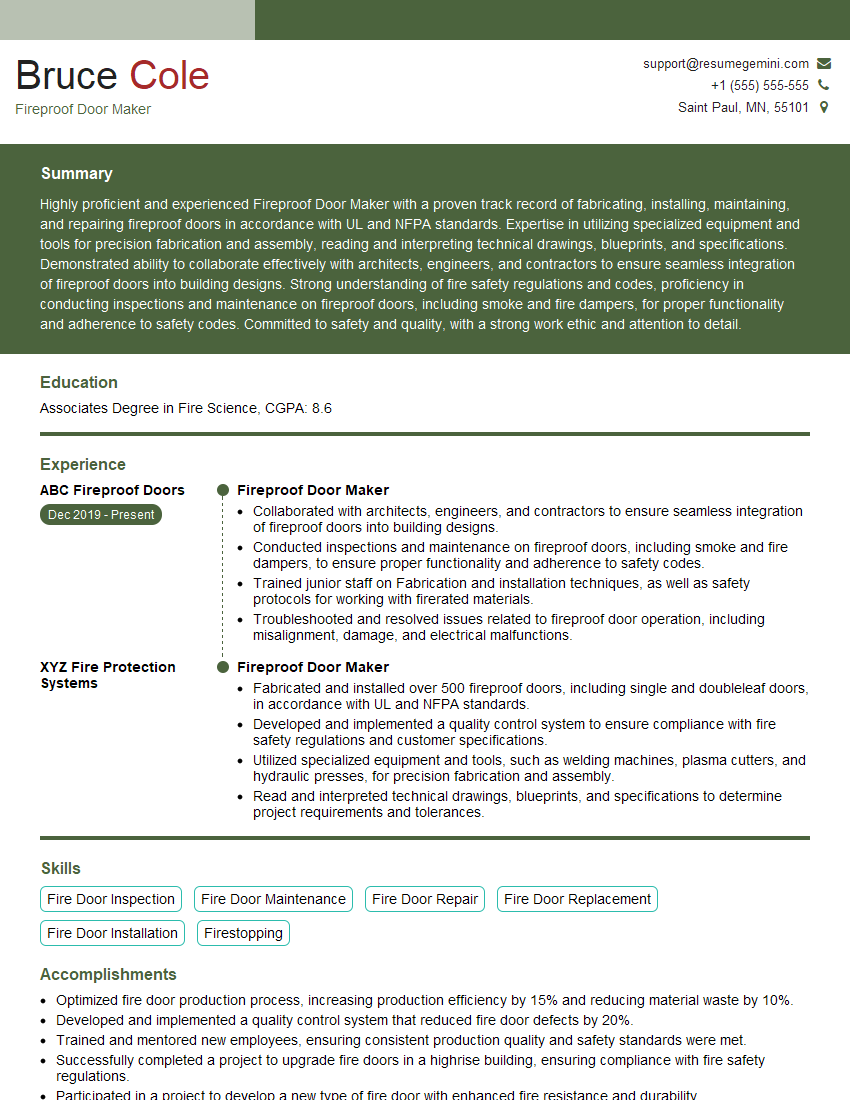

Bruce Cole

Fireproof Door Maker

Summary

Highly proficient and experienced Fireproof Door Maker with a proven track record of fabricating, installing, maintaining, and repairing fireproof doors in accordance with UL and NFPA standards. Expertise in utilizing specialized equipment and tools for precision fabrication and assembly, reading and interpreting technical drawings, blueprints, and specifications. Demonstrated ability to collaborate effectively with architects, engineers, and contractors to ensure seamless integration of fireproof doors into building designs. Strong understanding of fire safety regulations and codes, proficiency in conducting inspections and maintenance on fireproof doors, including smoke and fire dampers, for proper functionality and adherence to safety codes. Committed to safety and quality, with a strong work ethic and attention to detail.

Education

Associates Degree in Fire Science

November 2015

Skills

- Fire Door Inspection

- Fire Door Maintenance

- Fire Door Repair

- Fire Door Replacement

- Fire Door Installation

- Firestopping

Work Experience

Fireproof Door Maker

- Collaborated with architects, engineers, and contractors to ensure seamless integration of fireproof doors into building designs.

- Conducted inspections and maintenance on fireproof doors, including smoke and fire dampers, to ensure proper functionality and adherence to safety codes.

- Trained junior staff on Fabrication and installation techniques, as well as safety protocols for working with firerated materials.

- Troubleshooted and resolved issues related to fireproof door operation, including misalignment, damage, and electrical malfunctions.

Fireproof Door Maker

- Fabricated and installed over 500 fireproof doors, including single and doubleleaf doors, in accordance with UL and NFPA standards.

- Developed and implemented a quality control system to ensure compliance with fire safety regulations and customer specifications.

- Utilized specialized equipment and tools, such as welding machines, plasma cutters, and hydraulic presses, for precision fabrication and assembly.

- Read and interpreted technical drawings, blueprints, and specifications to determine project requirements and tolerances.

Accomplishments

- Optimized fire door production process, increasing production efficiency by 15% and reducing material waste by 10%.

- Developed and implemented a quality control system that reduced fire door defects by 20%.

- Trained and mentored new employees, ensuring consistent production quality and safety standards were met.

- Successfully completed a project to upgrade fire doors in a highrise building, ensuring compliance with fire safety regulations.

- Participated in a project to develop a new type of fire door with enhanced fire resistance and durability.

Awards

- Received the Employee of the Month award for consistently exceeding production targets and maintaining high quality standards.

- Was recognized by the company for outstanding contribution to the production of highquality fire doors.

- Received a commendation from the fire marshal for exceptional craftsmanship and adherence to fire safety standards.

- Won the Excellence in Fire Safety award for consistently producing highquality fire doors.

Certificates

- NICET Level III Firestopping Inspector

- Certified Fire Door Inspector (CFDI)

- Certified Firestop Specialist (CFS)

- NFPA 80 Fire Door Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fireproof Door Maker

- Highlight your experience in fabricating and installing fireproof doors in accordance with UL and NFPA standards.

- Quantify your accomplishments by providing specific numbers and metrics, such as the number of fireproof doors you have fabricated and installed.

- Demonstrate your knowledge of fire safety regulations and codes by providing examples of your involvement in developing and implementing quality control systems.

- Showcase your ability to collaborate effectively with architects, engineers, and contractors by providing examples of projects where you have successfully integrated fireproof doors into building designs.

- Emphasize your commitment to safety by highlighting your experience in conducting inspections and maintenance on fireproof doors, including smoke and fire dampers.

Essential Experience Highlights for a Strong Fireproof Door Maker Resume

- Fabricate and install fireproof doors, including single and doubleleaf doors, in accordance with UL and NFPA standards.

- Develop and implement quality control systems to ensure compliance with fire safety regulations and customer specifications.

- Utilize specialized equipment and tools, such as welding machines, plasma cutters, and hydraulic presses, for precision fabrication and assembly.

- Read and interpret technical drawings, blueprints, and specifications to determine project requirements and tolerances.

- Collaborate with architects, engineers, and contractors to ensure seamless integration of fireproof doors into building designs.

- Conduct inspections and maintenance on fireproof doors, including smoke and fire dampers, to ensure proper functionality and adherence to safety codes.

- Train junior staff on fabrication and installation techniques, as well as safety protocols for working with fire-rated materials.

- Troubleshoot and resolve issues related to fireproof door operation, including misalignment, damage, and electrical malfunctions.

Frequently Asked Questions (FAQ’s) For Fireproof Door Maker

What are the key skills required to be a Fireproof Door Maker?

The key skills required to be a Fireproof Door Maker include the ability to fabricate and install fireproof doors in accordance with UL and NFPA standards, knowledge of fire safety regulations and codes, proficiency in using specialized equipment and tools, and the ability to read and interpret technical drawings and blueprints.

What are the career opportunities for a Fireproof Door Maker?

The career opportunities for a Fireproof Door Maker include working as a Fire Door Inspector, Fire Door Maintenance Technician, Fire Door Repair Technician, Fire Door Replacement Specialist, and Fire Door Installation Specialist.

What is the average salary for a Fireproof Door Maker?

The average salary for a Fireproof Door Maker in the United States is around $50,000 per year.

What are the educational requirements to become a Fireproof Door Maker?

The educational requirements to become a Fireproof Door Maker typically include an Associates Degree in Fire Science or a related field.

What are the certification requirements to become a Fireproof Door Maker?

There are no specific certification requirements to become a Fireproof Door Maker, but obtaining certifications in fire safety and fire protection can be beneficial.

What are the job duties of a Fireproof Door Maker?

The job duties of a Fireproof Door Maker include fabricating, installing, maintaining, and repairing fireproof doors in accordance with UL and NFPA standards, conducting inspections and maintenance on fireproof doors, including smoke and fire dampers, and collaborating with architects, engineers, and contractors to ensure seamless integration of fireproof doors into building designs.

What are the safety requirements for a Fireproof Door Maker?

The safety requirements for a Fireproof Door Maker include wearing appropriate personal protective equipment, such as gloves, safety glasses, and a hard hat, and following all safety protocols and procedures when working with fire-rated materials and equipment.