Are you a seasoned Flake Cutter Operator seeking a new career path? Discover our professionally built Flake Cutter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

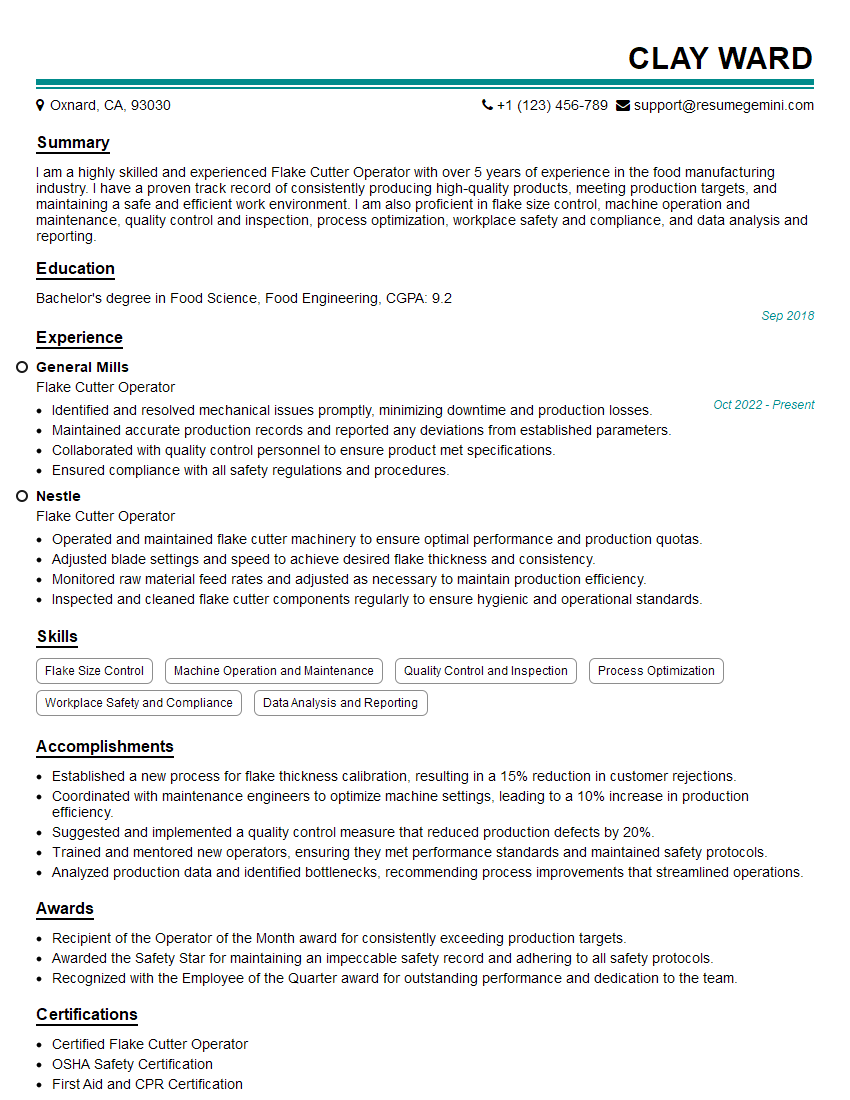

Clay Ward

Flake Cutter Operator

Summary

I am a highly skilled and experienced Flake Cutter Operator with over 5 years of experience in the food manufacturing industry. I have a proven track record of consistently producing high-quality products, meeting production targets, and maintaining a safe and efficient work environment. I am also proficient in flake size control, machine operation and maintenance, quality control and inspection, process optimization, workplace safety and compliance, and data analysis and reporting.

Education

Bachelor’s degree in Food Science, Food Engineering

September 2018

Skills

- Flake Size Control

- Machine Operation and Maintenance

- Quality Control and Inspection

- Process Optimization

- Workplace Safety and Compliance

- Data Analysis and Reporting

Work Experience

Flake Cutter Operator

- Identified and resolved mechanical issues promptly, minimizing downtime and production losses.

- Maintained accurate production records and reported any deviations from established parameters.

- Collaborated with quality control personnel to ensure product met specifications.

- Ensured compliance with all safety regulations and procedures.

Flake Cutter Operator

- Operated and maintained flake cutter machinery to ensure optimal performance and production quotas.

- Adjusted blade settings and speed to achieve desired flake thickness and consistency.

- Monitored raw material feed rates and adjusted as necessary to maintain production efficiency.

- Inspected and cleaned flake cutter components regularly to ensure hygienic and operational standards.

Accomplishments

- Established a new process for flake thickness calibration, resulting in a 15% reduction in customer rejections.

- Coordinated with maintenance engineers to optimize machine settings, leading to a 10% increase in production efficiency.

- Suggested and implemented a quality control measure that reduced production defects by 20%.

- Trained and mentored new operators, ensuring they met performance standards and maintained safety protocols.

- Analyzed production data and identified bottlenecks, recommending process improvements that streamlined operations.

Awards

- Recipient of the Operator of the Month award for consistently exceeding production targets.

- Awarded the Safety Star for maintaining an impeccable safety record and adhering to all safety protocols.

- Recognized with the Employee of the Quarter award for outstanding performance and dedication to the team.

Certificates

- Certified Flake Cutter Operator

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flake Cutter Operator

- Use strong action verbs to describe your accomplishments.

- Provide specific examples of your skills and experience with flake cutting machines.

- Highlight your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible.

Essential Experience Highlights for a Strong Flake Cutter Operator Resume

- Operate flake cutting machines to produce flakes of uniform size, thickness, and shape.

- Monitor and adjust machine settings to ensure optimal performance and product quality.

- Perform regular maintenance and cleaning of flake cutting machines to ensure proper operation.

- Inspect flakes for defects and ensure compliance with quality standards.

- Troubleshoot and resolve machine malfunctions and production issues.

- Maintain a clean and organized work area.

- Follow all safety protocols and procedures.

Frequently Asked Questions (FAQ’s) For Flake Cutter Operator

What is the role of a Flake Cutter Operator?

Flake Cutter Operators are responsible for operating flake cutting machines to produce flakes of uniform size, thickness, and shape. They also monitor and adjust machine settings to ensure optimal performance and product quality, perform regular maintenance and cleaning of flake cutting machines, inspect flakes for defects and ensure compliance with quality standards, troubleshoot and resolve machine malfunctions and production issues, maintain a clean and organized work area, and follow all safety protocols and procedures.

What are the qualifications for a Flake Cutter Operator?

Flake Cutter Operators typically need a high school diploma or equivalent, as well as some experience operating food processing machinery. They should also have a strong understanding of food safety and quality control procedures.

What is the work environment of a Flake Cutter Operator?

Flake Cutter Operators typically work in food processing plants. They typically work in a fast-paced environment and may be required to work long hours, including weekends and holidays.

What are the career prospects for a Flake Cutter Operator?

Flake Cutter Operators can advance to positions such as Production Supervisor or Quality Control Manager. They may also be able to start their own businesses.

What are the challenges of being a Flake Cutter Operator?

Flake Cutter Operators may face challenges such as working in a fast-paced environment, working long hours, and working with sharp machinery.

What are the benefits of being a Flake Cutter Operator?

Flake Cutter Operators can enjoy benefits such as a steady income, opportunities for advancement, and the satisfaction of working in a food production environment.