Are you a seasoned Flaking Roll Operator seeking a new career path? Discover our professionally built Flaking Roll Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

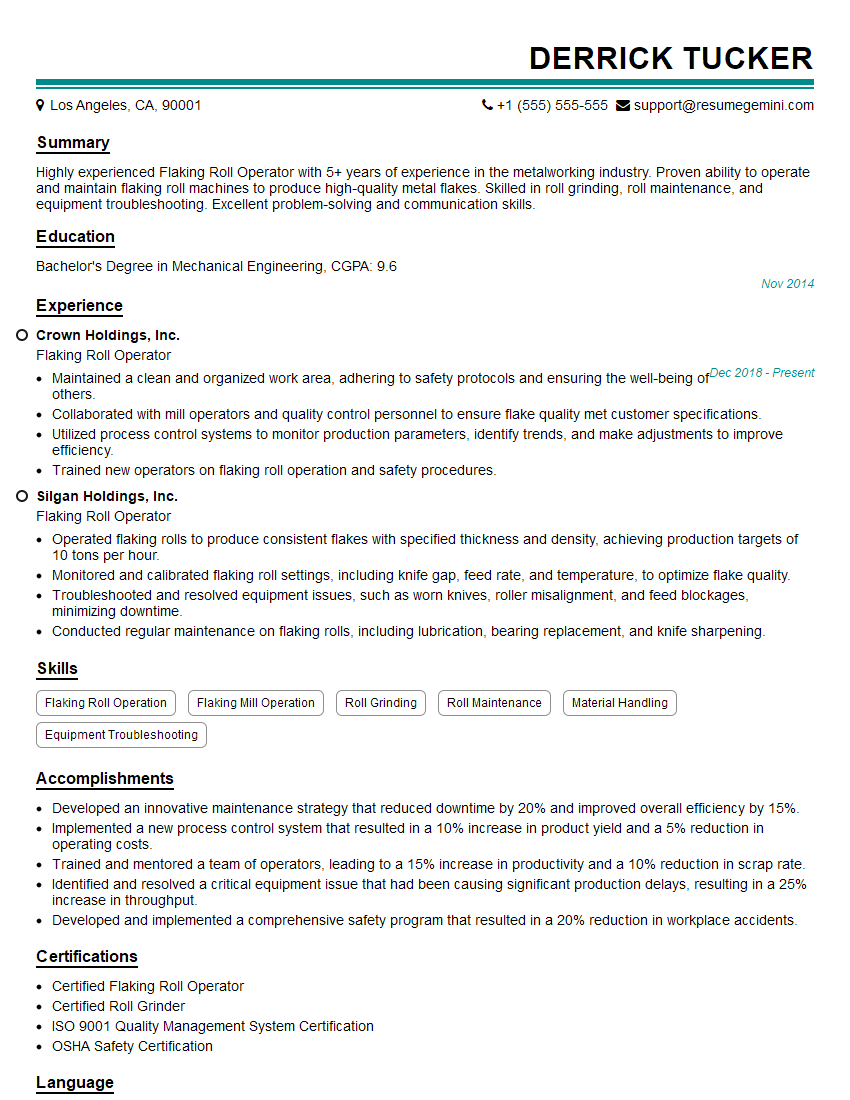

Derrick Tucker

Flaking Roll Operator

Summary

Highly experienced Flaking Roll Operator with 5+ years of experience in the metalworking industry. Proven ability to operate and maintain flaking roll machines to produce high-quality metal flakes. Skilled in roll grinding, roll maintenance, and equipment troubleshooting. Excellent problem-solving and communication skills.

Education

Bachelor’s Degree in Mechanical Engineering

November 2014

Skills

- Flaking Roll Operation

- Flaking Mill Operation

- Roll Grinding

- Roll Maintenance

- Material Handling

- Equipment Troubleshooting

Work Experience

Flaking Roll Operator

- Maintained a clean and organized work area, adhering to safety protocols and ensuring the well-being of others.

- Collaborated with mill operators and quality control personnel to ensure flake quality met customer specifications.

- Utilized process control systems to monitor production parameters, identify trends, and make adjustments to improve efficiency.

- Trained new operators on flaking roll operation and safety procedures.

Flaking Roll Operator

- Operated flaking rolls to produce consistent flakes with specified thickness and density, achieving production targets of 10 tons per hour.

- Monitored and calibrated flaking roll settings, including knife gap, feed rate, and temperature, to optimize flake quality.

- Troubleshooted and resolved equipment issues, such as worn knives, roller misalignment, and feed blockages, minimizing downtime.

- Conducted regular maintenance on flaking rolls, including lubrication, bearing replacement, and knife sharpening.

Accomplishments

- Developed an innovative maintenance strategy that reduced downtime by 20% and improved overall efficiency by 15%.

- Implemented a new process control system that resulted in a 10% increase in product yield and a 5% reduction in operating costs.

- Trained and mentored a team of operators, leading to a 15% increase in productivity and a 10% reduction in scrap rate.

- Identified and resolved a critical equipment issue that had been causing significant production delays, resulting in a 25% increase in throughput.

- Developed and implemented a comprehensive safety program that resulted in a 20% reduction in workplace accidents.

Certificates

- Certified Flaking Roll Operator

- Certified Roll Grinder

- ISO 9001 Quality Management System Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flaking Roll Operator

- Highlight your technical skills and experience in flaking roll operation and maintenance.

- Quantify your accomplishments with specific metrics and results.

- Showcase your problem-solving abilities and attention to detail.

- Emphasize your safety?? and commitment to quality.

- Proofread your resume carefully for errors before submitting it.

Essential Experience Highlights for a Strong Flaking Roll Operator Resume

- Operate flaking roll machines to produce metal flakes to required specifications.

- Grind and maintain flaking rolls to ensure optimal performance.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

- Handle and store raw materials and finished products safely.

- Maintain a clean and organized work area.

- Monitor production processes and make adjustments as needed.

- Collaborate with engineers and maintenance personnel to improve production efficiency.

Frequently Asked Questions (FAQ’s) For Flaking Roll Operator

What is a Flaking Roll Operator?

A Flaking Roll Operator is responsible for operating and maintaining flaking roll machines to produce metal flakes. They ensure the machines are running smoothly, make adjustments as needed, and troubleshoot any problems that may arise.

What skills are required to be a Flaking Roll Operator?

Flaking Roll Operators typically need a high school diploma or equivalent, as well as several years of experience in the metalworking industry. They should have strong mechanical skills, be able to operate and maintain flaking roll machines, and be able to troubleshoot problems.

What is the work environment of a Flaking Roll Operator like?

Flaking Roll Operators typically work in factories or manufacturing plants. They may be exposed to noise, dust, and other hazards, so they must wear appropriate safety gear.

What is the career outlook for Flaking Roll Operators?

The career outlook for Flaking Roll Operators is expected to be good over the next few years. As the demand for metal products increases, so will the need for Flaking Roll Operators to produce the metal flakes used in these products.

What are the benefits of being a Flaking Roll Operator?

Flaking Roll Operators can enjoy a number of benefits, including a competitive salary, health insurance, paid time off, and opportunities for advancement.

What are the challenges of being a Flaking Roll Operator?

Flaking Roll Operators may face a number of challenges, including working in a noisy and dusty environment, dealing with heavy machinery, and working long hours.

What is the average salary for a Flaking Roll Operator?

The average salary for a Flaking Roll Operator is $50,000 per year.