Are you a seasoned Flanging Roll Operator seeking a new career path? Discover our professionally built Flanging Roll Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

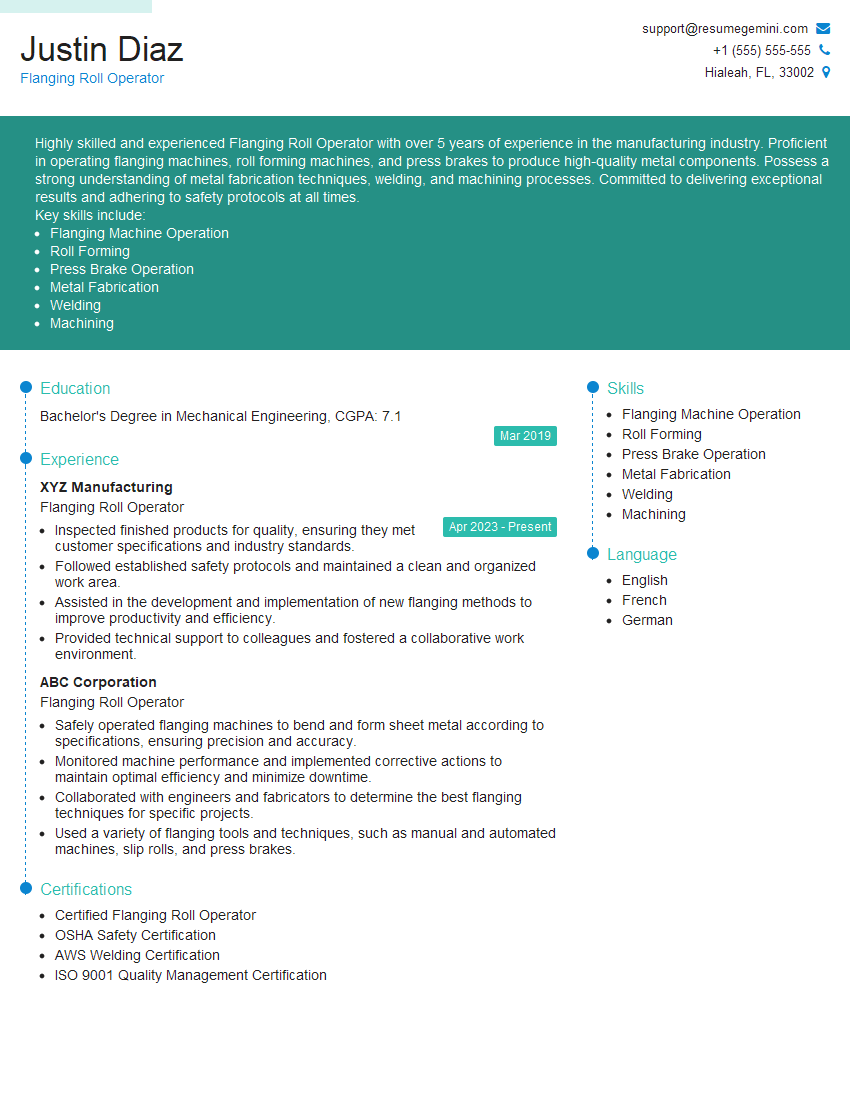

Justin Diaz

Flanging Roll Operator

Summary

Highly skilled and experienced Flanging Roll Operator with over 5 years of experience in the manufacturing industry. Proficient in operating flanging machines, roll forming machines, and press brakes to produce high-quality metal components. Possess a strong understanding of metal fabrication techniques, welding, and machining processes. Committed to delivering exceptional results and adhering to safety protocols at all times.

Key skills include:

- Flanging Machine Operation

- Roll Forming

- Press Brake Operation

- Metal Fabrication

- Welding

- Machining

Education

Bachelor’s Degree in Mechanical Engineering

March 2019

Skills

- Flanging Machine Operation

- Roll Forming

- Press Brake Operation

- Metal Fabrication

- Welding

- Machining

Work Experience

Flanging Roll Operator

- Inspected finished products for quality, ensuring they met customer specifications and industry standards.

- Followed established safety protocols and maintained a clean and organized work area.

- Assisted in the development and implementation of new flanging methods to improve productivity and efficiency.

- Provided technical support to colleagues and fostered a collaborative work environment.

Flanging Roll Operator

- Safely operated flanging machines to bend and form sheet metal according to specifications, ensuring precision and accuracy.

- Monitored machine performance and implemented corrective actions to maintain optimal efficiency and minimize downtime.

- Collaborated with engineers and fabricators to determine the best flanging techniques for specific projects.

- Used a variety of flanging tools and techniques, such as manual and automated machines, slip rolls, and press brakes.

Certificates

- Certified Flanging Roll Operator

- OSHA Safety Certification

- AWS Welding Certification

- ISO 9001 Quality Management Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flanging Roll Operator

- Highlight your relevant skills and experience in the manufacturing industry, especially in flanging and roll forming operations.

- Quantify your accomplishments and provide specific examples of your contributions to previous projects.

- Showcase your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Proofread your resume carefully for errors in grammar, spelling, and formatting.

Essential Experience Highlights for a Strong Flanging Roll Operator Resume

- Operate and maintain flanging machines to form and shape metal sheets into desired flange profiles.

- Set up and adjust machine parameters, including roll gap, forming speed, and pressure.

- Inspect raw materials and finished products to ensure quality and adherence to specifications.

- Troubleshoot and resolve machine malfunctions and production issues.

- Maintain a clean and safe work environment in accordance with industry standards.

- Collaborate with other team members to achieve production goals and meet customer requirements.

Frequently Asked Questions (FAQ’s) For Flanging Roll Operator

What is a Flanging Roll Operator?

A Flanging Roll Operator is responsible for operating and maintaining flanging machines to form and shape metal sheets into desired flange profiles. They set up and adjust machine parameters, inspect raw materials and finished products, troubleshoot machine malfunctions, and maintain a safe work environment.

What skills are required to be a successful Flanging Roll Operator?

Successful Flanging Roll Operators typically possess skills in flanging machine operation, roll forming, press brake operation, metal fabrication, welding, and machining. They should also have a strong understanding of safety protocols and be able to work independently and as part of a team.

What are the career prospects for Flanging Roll Operators?

Flanging Roll Operators can advance their careers by gaining experience and developing specialized skills. They may become supervisors or managers in manufacturing operations or pursue roles in quality control, engineering, or sales.

What is the average salary for a Flanging Roll Operator?

The average salary for a Flanging Roll Operator can vary depending on experience, location, and industry. According to Indeed, the average salary for Flanging Roll Operators in the United States is around $25 per hour.

What is the job outlook for Flanging Roll Operators?

The job outlook for Flanging Roll Operators is expected to be stable over the next few years. The demand for skilled manufacturing workers is increasing, and Flanging Roll Operators play a vital role in the production of metal components for various industries.