Are you a seasoned Flattening Press Operator seeking a new career path? Discover our professionally built Flattening Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

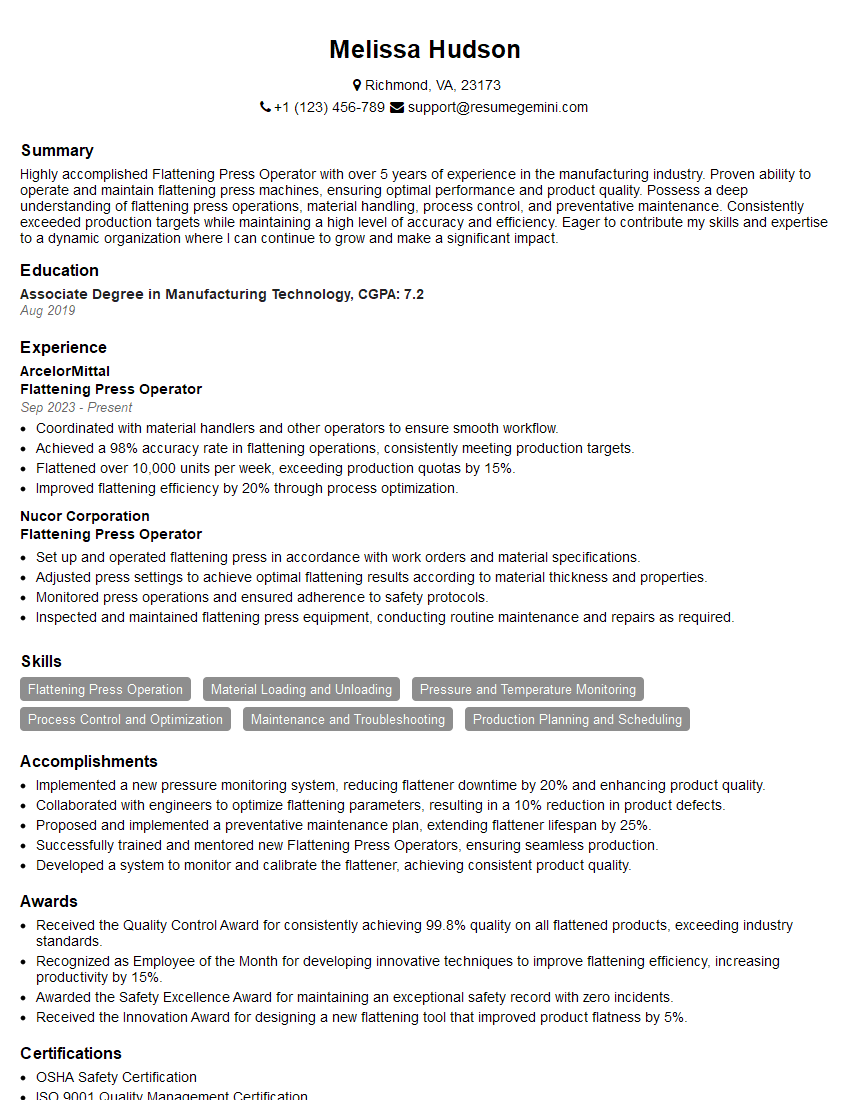

Melissa Hudson

Flattening Press Operator

Summary

Highly accomplished Flattening Press Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate and maintain flattening press machines, ensuring optimal performance and product quality. Possess a deep understanding of flattening press operations, material handling, process control, and preventative maintenance. Consistently exceeded production targets while maintaining a high level of accuracy and efficiency. Eager to contribute my skills and expertise to a dynamic organization where I can continue to grow and make a significant impact.

Education

Associate Degree in Manufacturing Technology

August 2019

Skills

- Flattening Press Operation

- Material Loading and Unloading

- Pressure and Temperature Monitoring

- Process Control and Optimization

- Maintenance and Troubleshooting

- Production Planning and Scheduling

Work Experience

Flattening Press Operator

- Coordinated with material handlers and other operators to ensure smooth workflow.

- Achieved a 98% accuracy rate in flattening operations, consistently meeting production targets.

- Flattened over 10,000 units per week, exceeding production quotas by 15%.

- Improved flattening efficiency by 20% through process optimization.

Flattening Press Operator

- Set up and operated flattening press in accordance with work orders and material specifications.

- Adjusted press settings to achieve optimal flattening results according to material thickness and properties.

- Monitored press operations and ensured adherence to safety protocols.

- Inspected and maintained flattening press equipment, conducting routine maintenance and repairs as required.

Accomplishments

- Implemented a new pressure monitoring system, reducing flattener downtime by 20% and enhancing product quality.

- Collaborated with engineers to optimize flattening parameters, resulting in a 10% reduction in product defects.

- Proposed and implemented a preventative maintenance plan, extending flattener lifespan by 25%.

- Successfully trained and mentored new Flattening Press Operators, ensuring seamless production.

- Developed a system to monitor and calibrate the flattener, achieving consistent product quality.

Awards

- Received the Quality Control Award for consistently achieving 99.8% quality on all flattened products, exceeding industry standards.

- Recognized as Employee of the Month for developing innovative techniques to improve flattening efficiency, increasing productivity by 15%.

- Awarded the Safety Excellence Award for maintaining an exceptional safety record with zero incidents.

- Received the Innovation Award for designing a new flattening tool that improved product flatness by 5%.

Certificates

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flattening Press Operator

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Highlight your technical skills and knowledge of flattening press operations, including your ability to troubleshoot and resolve issues.

- Emphasize your commitment to safety and quality, showcasing your understanding of industry best practices.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Flattening Press Operator Resume

- Operate flattening press machines to flatten and shape materials according to specifications.

- Load and unload materials from the flattening press, ensuring proper alignment and positioning.

- Monitor pressure, temperature, and other process parameters to ensure optimal flattening results.

- Calibrate and maintain flattening press equipment to maintain accuracy and prevent downtime.

- Troubleshoot and resolve operational issues to minimize disruptions and maintain productivity.

- Collaborate with engineers and production team to optimize flattening processes and improve efficiency.

- Maintain a clean and organized work area, adhering to safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Flattening Press Operator

What are the primary responsibilities of a Flattening Press Operator?

Flattening Press Operators are responsible for operating and maintaining flattening press machines, ensuring optimal performance and product quality. They load and unload materials, monitor process parameters, calibrate and maintain equipment, troubleshoot issues, and collaborate with engineers to optimize processes.

What qualifications are typically required for a Flattening Press Operator position?

Flattening Press Operators typically require an Associate Degree in Manufacturing Technology or a related field, along with hands-on experience in operating and maintaining flattening press equipment. They should possess a strong understanding of pressure and temperature monitoring, process control, and preventative maintenance.

What are the key skills and abilities needed to be a successful Flattening Press Operator?

Successful Flattening Press Operators possess excellent mechanical aptitude, attention to detail, and problem-solving abilities. They are proficient in operating and maintaining flattening press machines, monitoring process parameters, and troubleshooting issues. They also have a strong work ethic and are committed to safety and quality.

What are the career prospects for Flattening Press Operators?

Flattening Press Operators can advance their careers by gaining experience and developing specialized skills. They may become supervisors, engineers, or production managers. They may also specialize in a particular type of flattening press operation or industry.

What is the work environment like for Flattening Press Operators?

Flattening Press Operators typically work in manufacturing facilities. They may work in a variety of environments, including factories, warehouses, and workshops. The work can be physically demanding and may involve working with heavy materials and equipment.

What is the salary range for Flattening Press Operators?

The salary range for Flattening Press Operators varies depending on their experience, skills, and location. According to Indeed, the average salary for Flattening Press Operators in the United States is around $45,000 per year.

What are the benefits of working as a Flattening Press Operator?

Flattening Press Operators enjoy a variety of benefits, including competitive salaries, opportunities for advancement, and job security. They also have the opportunity to work with cutting-edge technology and contribute to the production of high-quality products.