Are you a seasoned Flexo Operator seeking a new career path? Discover our professionally built Flexo Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

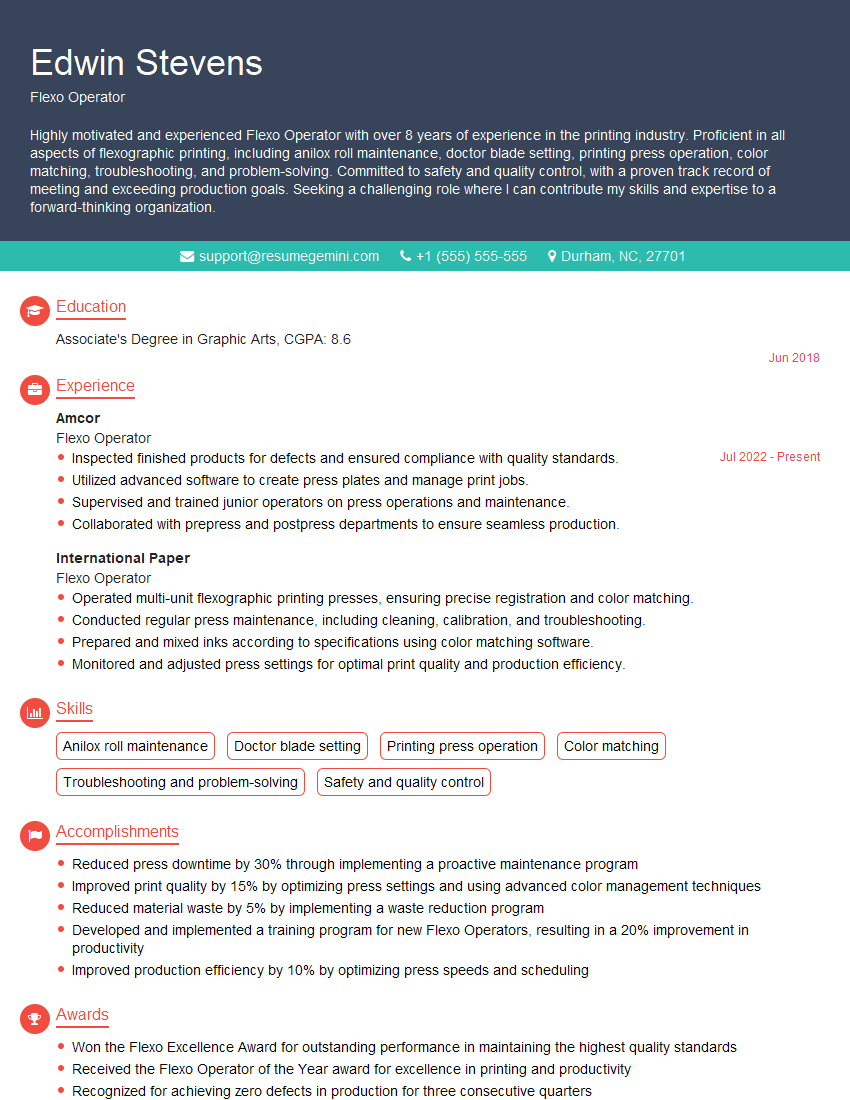

Edwin Stevens

Flexo Operator

Summary

Highly motivated and experienced Flexo Operator with over 8 years of experience in the printing industry. Proficient in all aspects of flexographic printing, including anilox roll maintenance, doctor blade setting, printing press operation, color matching, troubleshooting, and problem-solving. Committed to safety and quality control, with a proven track record of meeting and exceeding production goals. Seeking a challenging role where I can contribute my skills and expertise to a forward-thinking organization.

Education

Associate’s Degree in Graphic Arts

June 2018

Skills

- Anilox roll maintenance

- Doctor blade setting

- Printing press operation

- Color matching

- Troubleshooting and problem-solving

- Safety and quality control

Work Experience

Flexo Operator

- Inspected finished products for defects and ensured compliance with quality standards.

- Utilized advanced software to create press plates and manage print jobs.

- Supervised and trained junior operators on press operations and maintenance.

- Collaborated with prepress and postpress departments to ensure seamless production.

Flexo Operator

- Operated multi-unit flexographic printing presses, ensuring precise registration and color matching.

- Conducted regular press maintenance, including cleaning, calibration, and troubleshooting.

- Prepared and mixed inks according to specifications using color matching software.

- Monitored and adjusted press settings for optimal print quality and production efficiency.

Accomplishments

- Reduced press downtime by 30% through implementing a proactive maintenance program

- Improved print quality by 15% by optimizing press settings and using advanced color management techniques

- Reduced material waste by 5% by implementing a waste reduction program

- Developed and implemented a training program for new Flexo Operators, resulting in a 20% improvement in productivity

- Improved production efficiency by 10% by optimizing press speeds and scheduling

Awards

- Won the Flexo Excellence Award for outstanding performance in maintaining the highest quality standards

- Received the Flexo Operator of the Year award for excellence in printing and productivity

- Recognized for achieving zero defects in production for three consecutive quarters

- Won the Safety Award for exemplary safety practices in the workplace

Certificates

- Flexographic Printing Technician (FPT)

- Certified Flexographic Printing Operator (CFPO)

- OSHA Safety Certification

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flexo Operator

- Highlight your experience and skills in flexographic printing, including specific techniques and technologies.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation.

Essential Experience Highlights for a Strong Flexo Operator Resume

- Operate flexographic printing presses to produce high-quality printed materials.

- Maintain and calibrate printing equipment, including anilox rolls and doctor blades.

- Match colors accurately and consistently to meet customer specifications.

- Troubleshoot and resolve printing problems to maximize production efficiency.

- Ensure compliance with safety and quality control standards.

- Monitor production processes to identify areas for improvement.

Frequently Asked Questions (FAQ’s) For Flexo Operator

What is the role of a Flexo Operator?

A Flexo Operator is responsible for operating flexographic printing presses to produce high-quality printed materials. They maintain and calibrate printing equipment, match colors accurately, troubleshoot and resolve printing problems, and ensure compliance with safety and quality control standards.

What skills are required to be a successful Flexo Operator?

Successful Flexo Operators typically have a strong understanding of flexographic printing principles and practices. They are proficient in the operation of flexographic printing presses, as well as in the maintenance and calibration of printing equipment. They also have strong color matching skills and are able to troubleshoot and resolve printing problems. Additionally, they are committed to safety and quality control.

What is the career outlook for Flexo Operators?

The career outlook for Flexo Operators is expected to be good over the next few years. The demand for printed materials is expected to remain strong, and flexographic printing is a cost-effective and versatile printing process. As a result, there should be a continued need for skilled Flexo Operators.

What are the earning prospects for Flexo Operators?

The earning prospects for Flexo Operators vary depending on their experience, skills, and location. However, Flexo Operators can typically earn a good wage. According to the U.S. Bureau of Labor Statistics, the median annual wage for Printing Press Operators was $47,980 in May 2021.

What are the working conditions for Flexo Operators?

Flexo Operators typically work in printing plants or other manufacturing facilities. They may work day or night shifts, and they may be required to work overtime to meet production deadlines. The work can be physically demanding, as Flexo Operators may be required to lift heavy materials and stand for long periods of time.

How can I become a Flexo Operator?

There are several ways to become a Flexo Operator. Some Flexo Operators learn the trade through on-the-job training. Others complete a formal apprenticeship program. There are also a number of colleges and technical schools that offer programs in flexographic printing.