Are you a seasoned Flexo Press Operator seeking a new career path? Discover our professionally built Flexo Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

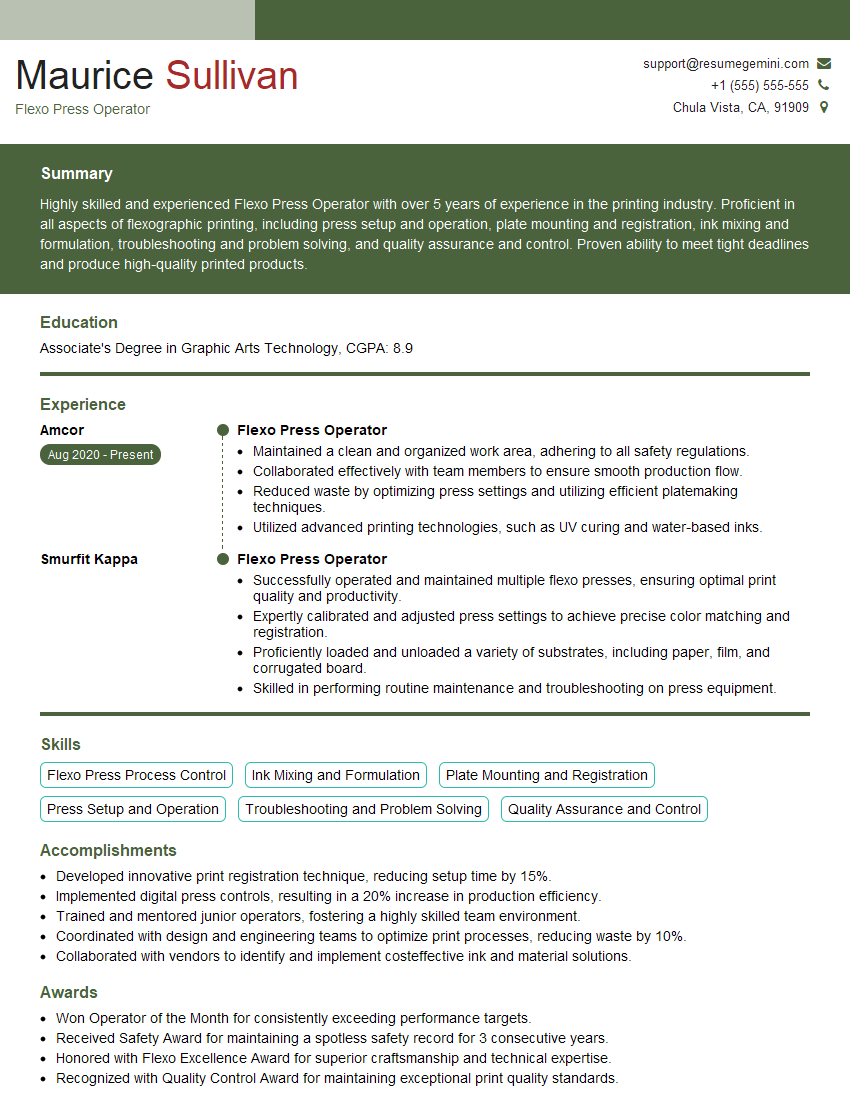

Maurice Sullivan

Flexo Press Operator

Summary

Highly skilled and experienced Flexo Press Operator with over 5 years of experience in the printing industry. Proficient in all aspects of flexographic printing, including press setup and operation, plate mounting and registration, ink mixing and formulation, troubleshooting and problem solving, and quality assurance and control. Proven ability to meet tight deadlines and produce high-quality printed products.

Education

Associate’s Degree in Graphic Arts Technology

July 2016

Skills

- Flexo Press Process Control

- Ink Mixing and Formulation

- Plate Mounting and Registration

- Press Setup and Operation

- Troubleshooting and Problem Solving

- Quality Assurance and Control

Work Experience

Flexo Press Operator

- Maintained a clean and organized work area, adhering to all safety regulations.

- Collaborated effectively with team members to ensure smooth production flow.

- Reduced waste by optimizing press settings and utilizing efficient platemaking techniques.

- Utilized advanced printing technologies, such as UV curing and water-based inks.

Flexo Press Operator

- Successfully operated and maintained multiple flexo presses, ensuring optimal print quality and productivity.

- Expertly calibrated and adjusted press settings to achieve precise color matching and registration.

- Proficiently loaded and unloaded a variety of substrates, including paper, film, and corrugated board.

- Skilled in performing routine maintenance and troubleshooting on press equipment.

Accomplishments

- Developed innovative print registration technique, reducing setup time by 15%.

- Implemented digital press controls, resulting in a 20% increase in production efficiency.

- Trained and mentored junior operators, fostering a highly skilled team environment.

- Coordinated with design and engineering teams to optimize print processes, reducing waste by 10%.

- Collaborated with vendors to identify and implement costeffective ink and material solutions.

Awards

- Won Operator of the Month for consistently exceeding performance targets.

- Received Safety Award for maintaining a spotless safety record for 3 consecutive years.

- Honored with Flexo Excellence Award for superior craftsmanship and technical expertise.

- Recognized with Quality Control Award for maintaining exceptional print quality standards.

Certificates

- Flexographic Process Specialist (FPS) Certification

- Flexo Plate Technician Certification (FPTC)

- Flexographic Quality Control Certification (FQCC)

- FTA Master Flexographer Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flexo Press Operator

- Highlight your experience in the flexographic printing industry.

- Showcase your knowledge of flexo press process control, ink mixing and formulation, plate mounting and registration, press setup and operation, troubleshooting and problem solving, and quality assurance and control.

- Include examples of your accomplishments in your resume, such as reducing waste, improving efficiency, or increasing productivity.

- Proofread your resume carefully before submitting it to potential employers.

Essential Experience Highlights for a Strong Flexo Press Operator Resume

- Set up and operate flexo presses to print a variety of substrates, including paper, plastic, and metal.

- Mix and formulate inks to achieve desired colors and densities.

- Mount and register printing plates to ensure accurate printing.

- Monitor press performance and make adjustments as needed to maintain quality and efficiency.

- Troubleshoot and resolve printing problems quickly and effectively.

- Conduct quality control inspections to ensure printed products meet customer specifications.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Flexo Press Operator

What is a Flexo Press Operator?

A Flexo Press Operator is responsible for operating a flexographic printing press to print a variety of substrates, including paper, plastic, and metal.

What are the key skills required for a Flexo Press Operator?

Key skills for a Flexo Press Operator include flexo press process control, ink mixing and formulation, plate mounting and registration, press setup and operation, troubleshooting and problem solving, and quality assurance and control.

What is the average salary for a Flexo Press Operator?

The average salary for a Flexo Press Operator in the United States is around $45,000 per year.

What are the job prospects for a Flexo Press Operator?

The job outlook for Flexo Press Operators is expected to grow by about 4% over the next decade.

What are the educational requirements for a Flexo Press Operator?

Most Flexo Press Operators have a high school diploma or an associate’s degree in graphic arts technology.

What are the career advancement opportunities for a Flexo Press Operator?

Flexo Press Operators can advance to positions such as Printing Supervisor, Production Manager, or Quality Control Manager.

What are the challenges of being a Flexo Press Operator?

Challenges of being a Flexo Press Operator include working in a fast-paced environment, meeting tight deadlines, and working with hazardous materials.