Are you a seasoned Flexographic Press Operator seeking a new career path? Discover our professionally built Flexographic Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

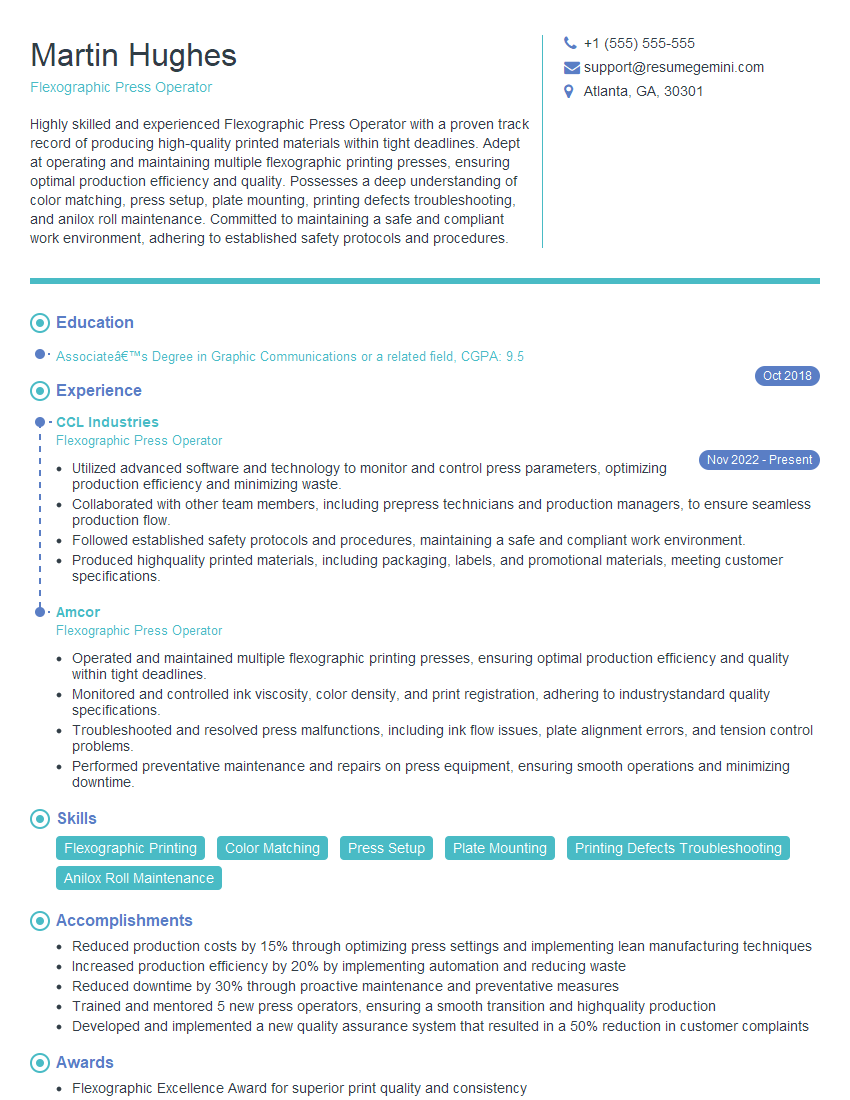

Martin Hughes

Flexographic Press Operator

Summary

Highly skilled and experienced Flexographic Press Operator with a proven track record of producing high-quality printed materials within tight deadlines. Adept at operating and maintaining multiple flexographic printing presses, ensuring optimal production efficiency and quality. Possesses a deep understanding of color matching, press setup, plate mounting, printing defects troubleshooting, and anilox roll maintenance. Committed to maintaining a safe and compliant work environment, adhering to established safety protocols and procedures.

Education

Associate’s Degree in Graphic Communications or a related field

October 2018

Skills

- Flexographic Printing

- Color Matching

- Press Setup

- Plate Mounting

- Printing Defects Troubleshooting

- Anilox Roll Maintenance

Work Experience

Flexographic Press Operator

- Utilized advanced software and technology to monitor and control press parameters, optimizing production efficiency and minimizing waste.

- Collaborated with other team members, including prepress technicians and production managers, to ensure seamless production flow.

- Followed established safety protocols and procedures, maintaining a safe and compliant work environment.

- Produced highquality printed materials, including packaging, labels, and promotional materials, meeting customer specifications.

Flexographic Press Operator

- Operated and maintained multiple flexographic printing presses, ensuring optimal production efficiency and quality within tight deadlines.

- Monitored and controlled ink viscosity, color density, and print registration, adhering to industrystandard quality specifications.

- Troubleshooted and resolved press malfunctions, including ink flow issues, plate alignment errors, and tension control problems.

- Performed preventative maintenance and repairs on press equipment, ensuring smooth operations and minimizing downtime.

Accomplishments

- Reduced production costs by 15% through optimizing press settings and implementing lean manufacturing techniques

- Increased production efficiency by 20% by implementing automation and reducing waste

- Reduced downtime by 30% through proactive maintenance and preventative measures

- Trained and mentored 5 new press operators, ensuring a smooth transition and highquality production

- Developed and implemented a new quality assurance system that resulted in a 50% reduction in customer complaints

Awards

- Flexographic Excellence Award for superior print quality and consistency

- Safety Excellence Award for exemplary safety practices and zero accidents

- Flexographic Innovation Award for developing a new printing process that improved color accuracy

- Employee of the Month for outstanding performance and dedication

Certificates

- Flexographic Printing Specialist (FPS)

- Certified Flexographic Press Operator (CFPO)

- Flexographic Technical Association (FTA) Member

- Printing Industries of America (PIA) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flexographic Press Operator

- Highlight your experience and skills in operating and maintaining flexographic printing presses, including specific models and technologies.

- Demonstrate your knowledge of color matching, press setup, plate mounting, printing defects troubleshooting, and anilox roll maintenance.

- Showcase your ability to work independently and as part of a team in a fast-paced production environment.

- Provide specific examples of how you have optimized production efficiency, minimized waste, and ensured quality control.

- Emphasize your commitment to safety and compliance in the workplace.

Essential Experience Highlights for a Strong Flexographic Press Operator Resume

- Operated and maintained multiple flexographic printing presses, ensuring optimal production efficiency and quality within tight deadlines.

- Monitored and controlled ink viscosity, color density, and print registration, adhering to industry-standard quality specifications.

- Troubleshooted and resolved press malfunctions, including ink flow issues, plate alignment errors, and tension control problems.

- Performed preventative maintenance and repairs on press equipment, ensuring smooth operations and minimizing downtime.

- Utilized advanced software and technology to monitor and control press parameters, optimizing production efficiency and minimizing waste.

- Collaborated with other team members, including prepress technicians and production managers, to ensure seamless production flow.

- Followed established safety protocols and procedures, maintaining a safe and compliant work environment.

- Produced high-quality printed materials, including packaging, labels, and promotional materials, meeting customer specifications.

Frequently Asked Questions (FAQ’s) For Flexographic Press Operator

What are the key skills required to be a successful Flexographic Press Operator?

Key skills include: operating and maintaining flexographic printing presses, color matching, press setup, plate mounting, printing defects troubleshooting, anilox roll maintenance, and a strong understanding of safety protocols.

What industries typically employ Flexographic Press Operators?

Flexographic Press Operators are employed in a variety of industries, including packaging, printing, and manufacturing.

What are the career advancement opportunities for Flexographic Press Operators?

With experience and additional training, Flexographic Press Operators can advance to roles such as Press Supervisor, Production Manager, or Quality Control Manager.

What is the average salary for a Flexographic Press Operator?

The average salary for a Flexographic Press Operator varies depending on experience, location, and industry, but typically ranges from $30,000 to $50,000 per year.

What are the safety precautions that Flexographic Press Operators must follow?

Flexographic Press Operators must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What are the typical working hours for a Flexographic Press Operator?

Flexographic Press Operators typically work full-time hours, which may include shift work, overtime, and weekends.

What are the physical demands of being a Flexographic Press Operator?

The job can involve lifting heavy materials, standing for long periods, and working in a fast-paced environment.