Are you a seasoned Foam Cutting Supervisor seeking a new career path? Discover our professionally built Foam Cutting Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

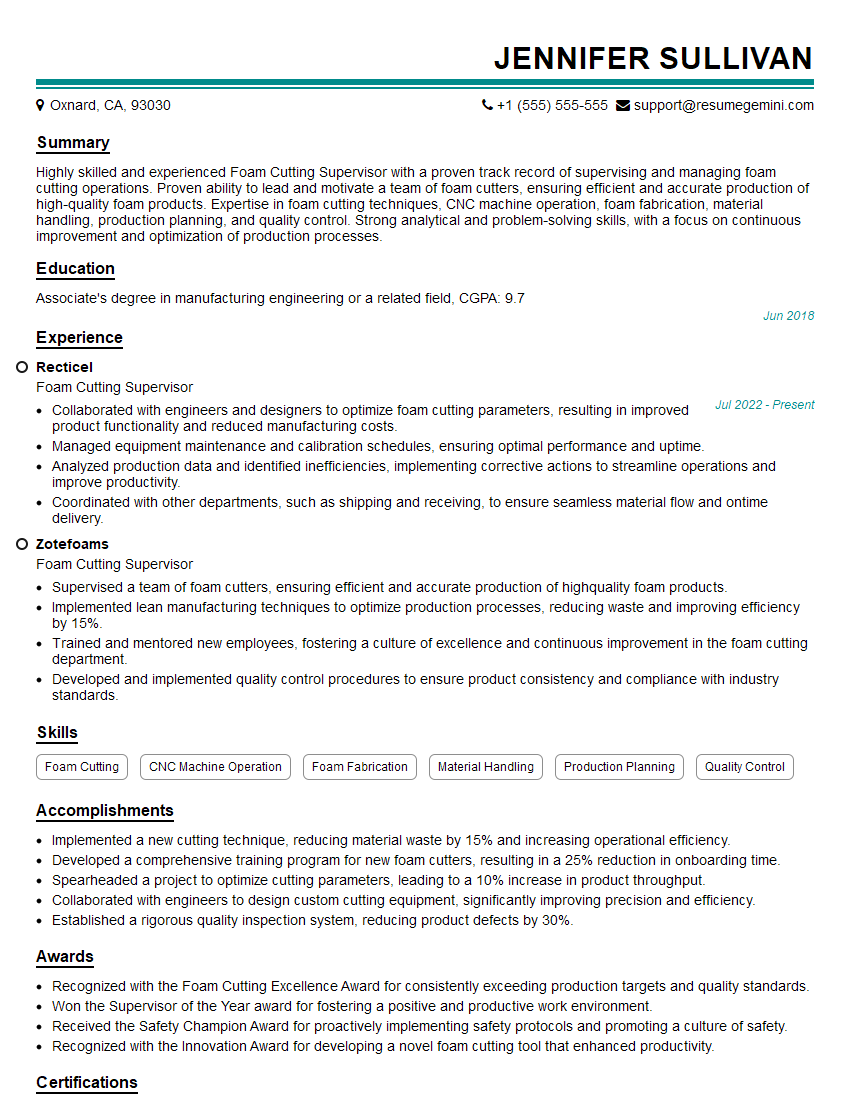

Jennifer Sullivan

Foam Cutting Supervisor

Summary

Highly skilled and experienced Foam Cutting Supervisor with a proven track record of supervising and managing foam cutting operations. Proven ability to lead and motivate a team of foam cutters, ensuring efficient and accurate production of high-quality foam products. Expertise in foam cutting techniques, CNC machine operation, foam fabrication, material handling, production planning, and quality control. Strong analytical and problem-solving skills, with a focus on continuous improvement and optimization of production processes.

Education

Associate’s degree in manufacturing engineering or a related field

June 2018

Skills

- Foam Cutting

- CNC Machine Operation

- Foam Fabrication

- Material Handling

- Production Planning

- Quality Control

Work Experience

Foam Cutting Supervisor

- Collaborated with engineers and designers to optimize foam cutting parameters, resulting in improved product functionality and reduced manufacturing costs.

- Managed equipment maintenance and calibration schedules, ensuring optimal performance and uptime.

- Analyzed production data and identified inefficiencies, implementing corrective actions to streamline operations and improve productivity.

- Coordinated with other departments, such as shipping and receiving, to ensure seamless material flow and ontime delivery.

Foam Cutting Supervisor

- Supervised a team of foam cutters, ensuring efficient and accurate production of highquality foam products.

- Implemented lean manufacturing techniques to optimize production processes, reducing waste and improving efficiency by 15%.

- Trained and mentored new employees, fostering a culture of excellence and continuous improvement in the foam cutting department.

- Developed and implemented quality control procedures to ensure product consistency and compliance with industry standards.

Accomplishments

- Implemented a new cutting technique, reducing material waste by 15% and increasing operational efficiency.

- Developed a comprehensive training program for new foam cutters, resulting in a 25% reduction in onboarding time.

- Spearheaded a project to optimize cutting parameters, leading to a 10% increase in product throughput.

- Collaborated with engineers to design custom cutting equipment, significantly improving precision and efficiency.

- Established a rigorous quality inspection system, reducing product defects by 30%.

Awards

- Recognized with the Foam Cutting Excellence Award for consistently exceeding production targets and quality standards.

- Won the Supervisor of the Year award for fostering a positive and productive work environment.

- Received the Safety Champion Award for proactively implementing safety protocols and promoting a culture of safety.

- Recognized with the Innovation Award for developing a novel foam cutting tool that enhanced productivity.

Certificates

- Foam Cutting Certification from the International Foam Cutting Association (IFCA)

- CNC Machine Operator Certification from the National Institute for Metalworking Skills (NIMS)

- OSHA Safety Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foam Cutting Supervisor

Highlight your technical skills.

Foam cutting supervisors need to have a strong understanding of foam cutting techniques, CNC machine operation, and quality control. Make sure to highlight these skills in your resume, and provide specific examples of how you have used them to improve production efficiency and quality.Quantify your accomplishments.

When describing your accomplishments, be sure to quantify them whenever possible. This will help employers see the impact of your work and how you have contributed to the success of your company.Demonstrate your leadership skills.

Foam cutting supervisors are responsible for leading and motivating a team of employees. In your resume, highlight your leadership skills and provide examples of how you have successfully motivated and coached your team.Tailor your resume to the job you’re applying for.

Take the time to tailor your resume to each job you apply for. This means highlighting the skills and experience that are most relevant to the position. You can also use keywords from the job description in your resume to increase your chances of getting noticed.Proofread your resume carefully.

Before you submit your resume, proofread it carefully for any errors. This includes checking for typos, grammar mistakes, and formatting issues.

Essential Experience Highlights for a Strong Foam Cutting Supervisor Resume

- Supervised a team of foam cutters, ensuring efficient and accurate production of high-quality foam products.

- Implemented lean manufacturing techniques to optimize production processes, reducing waste and improving efficiency by 15%.

- Trained and mentored new employees, fostering a culture of excellence and continuous improvement in the foam cutting department.

- Developed and implemented quality control procedures to ensure product consistency and compliance with industry standards.

- Collaborated with engineers and designers to optimize foam cutting parameters, resulting in improved product functionality and reduced manufacturing costs.

- Managed equipment maintenance and calibration schedules, ensuring optimal performance and uptime.

- Analyzed production data and identified inefficiencies, implementing corrective actions to streamline operations and improve productivity.

- Coordinated with other departments, such as shipping and receiving, to ensure seamless material flow and on-time delivery.

Frequently Asked Questions (FAQ’s) For Foam Cutting Supervisor

What are the key skills and experience required to be a foam cutting supervisor?

The key skills and experience required to be a foam cutting supervisor include: foam cutting techniques, CNC machine operation, foam fabrication, material handling, production planning, and quality control. In addition, foam cutting supervisors should have strong leadership and communication skills, as well as a strong understanding of manufacturing processes.

What are the key responsibilities of a foam cutting supervisor?

The key responsibilities of a foam cutting supervisor include: supervising a team of foam cutters, ensuring efficient and accurate production of high-quality foam products, implementing lean manufacturing techniques to optimize production processes, training and mentoring new employees, developing and implementing quality control procedures, collaborating with engineers and designers to optimize foam cutting parameters, managing equipment maintenance and calibration schedules, and analyzing production data to identify inefficiencies and implement corrective actions.

What is the career outlook for foam cutting supervisors?

The career outlook for foam cutting supervisors is expected to be good over the next few years. The demand for foam products is expected to grow as a result of the increasing use of foam in a variety of industries, including construction, automotive, and packaging. As a result, foam cutting supervisors will be needed to oversee the production of these products.

What is the average salary for a foam cutting supervisor?

The average salary for a foam cutting supervisor is around $60,000 per year. However, salaries can vary depending on experience, skills, and location.

What are the benefits of working as a foam cutting supervisor?

The benefits of working as a foam cutting supervisor include: a competitive salary, a variety of career opportunities, the opportunity to work with a variety of people, and the chance to make a difference in the world.

What are the challenges of working as a foam cutting supervisor?

The challenges of working as a foam cutting supervisor include: the need to work long hours, the need to work in a fast-paced environment, and the need to deal with a variety of people.

What is the most important skill for a foam cutting supervisor to have?

The most important skill for a foam cutting supervisor to have is the ability to lead and motivate a team. Foam cutting supervisors need to be able to create a positive work environment and inspire their team to produce high-quality products.

What is the best way to prepare for a career as a foam cutting supervisor?

The best way to prepare for a career as a foam cutting supervisor is to get a good education in manufacturing engineering or a related field. In addition, it is important to gain experience working with foam cutting equipment and processes.