Are you a seasoned Foam Rubber Molder seeking a new career path? Discover our professionally built Foam Rubber Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

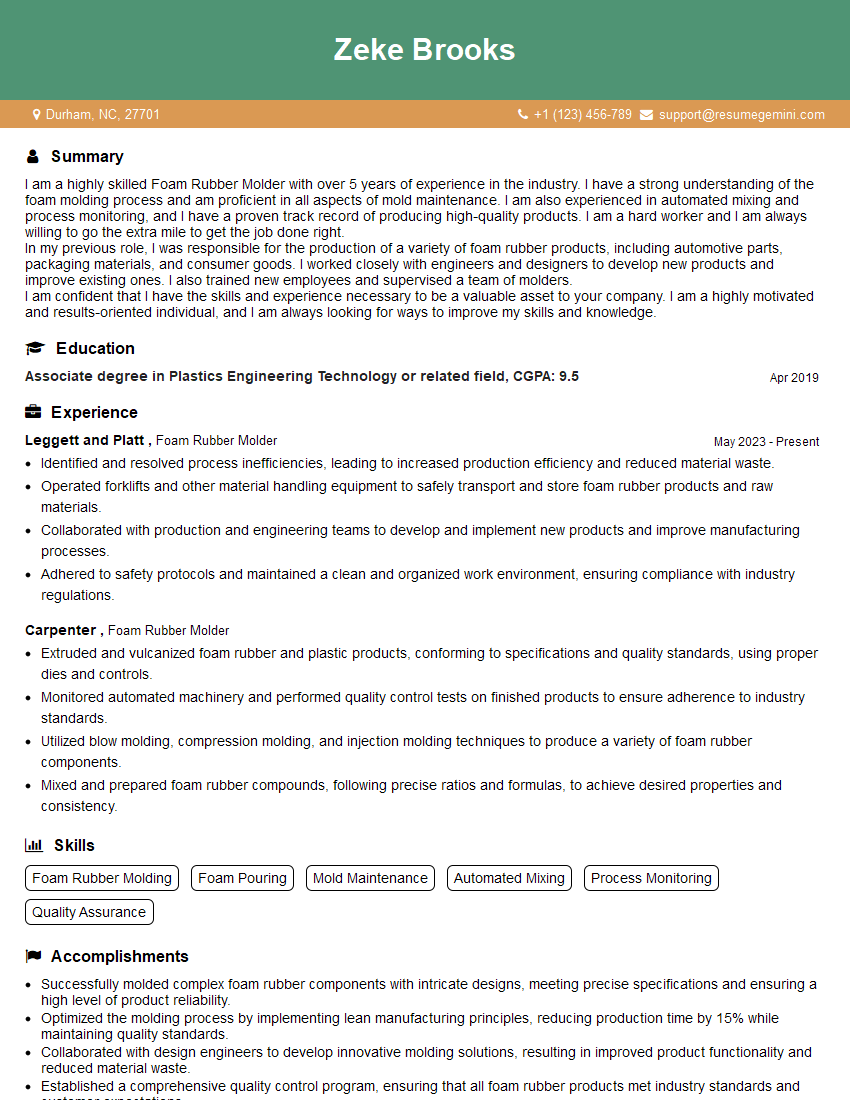

Zeke Brooks

Foam Rubber Molder

Summary

I am a highly skilled Foam Rubber Molder with over 5 years of experience in the industry. I have a strong understanding of the foam molding process and am proficient in all aspects of mold maintenance. I am also experienced in automated mixing and process monitoring, and I have a proven track record of producing high-quality products. I am a hard worker and I am always willing to go the extra mile to get the job done right.

In my previous role, I was responsible for the production of a variety of foam rubber products, including automotive parts, packaging materials, and consumer goods. I worked closely with engineers and designers to develop new products and improve existing ones. I also trained new employees and supervised a team of molders.

I am confident that I have the skills and experience necessary to be a valuable asset to your company. I am a highly motivated and results-oriented individual, and I am always looking for ways to improve my skills and knowledge.

Education

Associate degree in Plastics Engineering Technology or related field

April 2019

Skills

- Foam Rubber Molding

- Foam Pouring

- Mold Maintenance

- Automated Mixing

- Process Monitoring

- Quality Assurance

Work Experience

Foam Rubber Molder

- Identified and resolved process inefficiencies, leading to increased production efficiency and reduced material waste.

- Operated forklifts and other material handling equipment to safely transport and store foam rubber products and raw materials.

- Collaborated with production and engineering teams to develop and implement new products and improve manufacturing processes.

- Adhered to safety protocols and maintained a clean and organized work environment, ensuring compliance with industry regulations.

Foam Rubber Molder

- Extruded and vulcanized foam rubber and plastic products, conforming to specifications and quality standards, using proper dies and controls.

- Monitored automated machinery and performed quality control tests on finished products to ensure adherence to industry standards.

- Utilized blow molding, compression molding, and injection molding techniques to produce a variety of foam rubber components.

- Mixed and prepared foam rubber compounds, following precise ratios and formulas, to achieve desired properties and consistency.

Accomplishments

- Successfully molded complex foam rubber components with intricate designs, meeting precise specifications and ensuring a high level of product reliability.

- Optimized the molding process by implementing lean manufacturing principles, reducing production time by 15% while maintaining quality standards.

- Collaborated with design engineers to develop innovative molding solutions, resulting in improved product functionality and reduced material waste.

- Established a comprehensive quality control program, ensuring that all foam rubber products met industry standards and customer expectations.

- Trained and mentored new foam rubber molders, fostering a culture of excellence and maintaining a high level of productivity.

Awards

- Recognized as Foam Rubber Molder of the Year for achieving exceptional production targets and maintaining highquality standards.

- Received the Innovation Award for developing a new molding technique that increased production efficiency by 20%.

- Awarded the Safety Excellence Award for maintaining an accidentfree work environment throughout the year.

Certificates

- Safety Training

- Foam Molding Course

- Quality Control Certification

- ANSI/OSHA Compliance Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foam Rubber Molder

- Highlight your experience in foam rubber molding, including the specific types of products you have worked with.

- Demonstrate your knowledge of the foam molding process, including the different types of molds and materials used.

- Showcase your skills in mold maintenance, including your ability to troubleshoot and repair problems.

- Emphasize your commitment to quality control and your ability to produce high-quality products.

Essential Experience Highlights for a Strong Foam Rubber Molder Resume

- Operate foam rubber molding machines to produce molded rubber products.

- Mix and pour foam rubber into molds, ensuring proper proportions and consistency.

- Maintain and repair molds, including cleaning, lubricating, and replacing worn parts.

- Monitor the molding process and make adjustments as needed to ensure product quality.

- Inspect finished products for defects and ensure they meet specifications.

- Troubleshoot and resolve production issues quickly and efficiently.

Frequently Asked Questions (FAQ’s) For Foam Rubber Molder

What is foam rubber molding?

Foam rubber molding is a manufacturing process used to create molded rubber products. The process involves mixing and pouring foam rubber into a mold, and then curing the rubber until it sets. Foam rubber molding is used to produce a variety of products, including automotive parts, packaging materials, and consumer goods.

What are the different types of foam rubber molding?

There are two main types of foam rubber molding: open-mold molding and closed-mold molding. In open-mold molding, the foam rubber is poured into a mold that is open at the top. In closed-mold molding, the foam rubber is poured into a mold that is closed on all sides.

What are the different types of foam rubber?

There are many different types of foam rubber, each with its own unique properties. Some of the most common types of foam rubber include polyurethane foam, latex foam, and memory foam.

What are the advantages of foam rubber molding?

Foam rubber molding offers a number of advantages over other manufacturing processes. These advantages include: – Lightweight: Foam rubber is a lightweight material, which makes it ideal for products that need to be transported or handled easily. – Durable: Foam rubber is a durable material that can withstand wear and tear. It is also resistant to chemicals and moisture. – Flexible: Foam rubber is a flexible material that can be molded into a variety of shapes and sizes. – Insulating: Foam rubber is an insulating material that can help to keep products warm or cold. – Sound-absorbing: Foam rubber is a sound-absorbing material that can help to reduce noise levels.

What are the disadvantages of foam rubber molding?

Foam rubber molding also has some disadvantages, including: – Cost: Foam rubber molding can be a relatively expensive manufacturing process. – Complexity: Foam rubber molding can be a complex process that requires specialized equipment and expertise. – Environmental concerns: Foam rubber is a petroleum-based product, and its production can have a negative impact on the environment.

What is the future of foam rubber molding?

The future of foam rubber molding is bright. As the demand for lightweight, durable, and flexible materials continues to grow, foam rubber molding is expected to become even more popular. In addition, new technologies are being developed to make foam rubber molding more efficient and environmentally friendly.