Are you a seasoned Forcer Maker seeking a new career path? Discover our professionally built Forcer Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

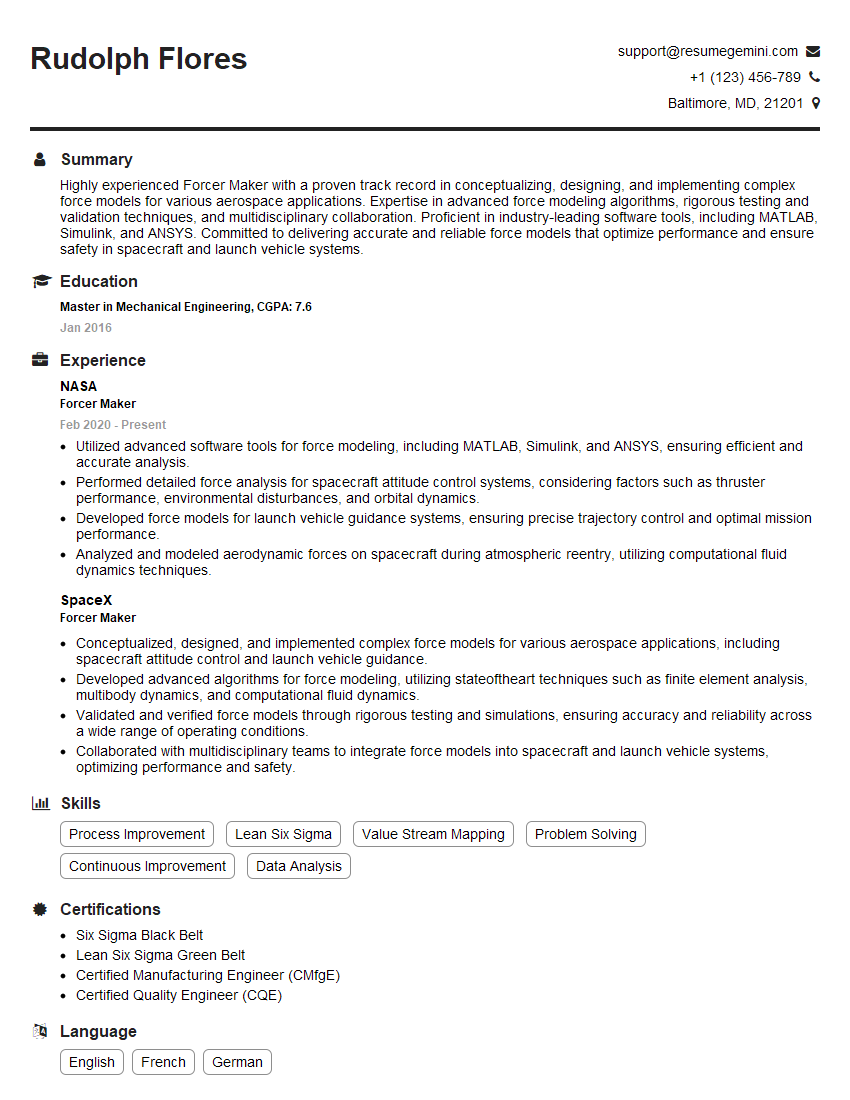

Rudolph Flores

Forcer Maker

Summary

Highly experienced Forcer Maker with a proven track record in conceptualizing, designing, and implementing complex force models for various aerospace applications. Expertise in advanced force modeling algorithms, rigorous testing and validation techniques, and multidisciplinary collaboration. Proficient in industry-leading software tools, including MATLAB, Simulink, and ANSYS. Committed to delivering accurate and reliable force models that optimize performance and ensure safety in spacecraft and launch vehicle systems.

Education

Master in Mechanical Engineering

January 2016

Skills

- Process Improvement

- Lean Six Sigma

- Value Stream Mapping

- Problem Solving

- Continuous Improvement

- Data Analysis

Work Experience

Forcer Maker

- Utilized advanced software tools for force modeling, including MATLAB, Simulink, and ANSYS, ensuring efficient and accurate analysis.

- Performed detailed force analysis for spacecraft attitude control systems, considering factors such as thruster performance, environmental disturbances, and orbital dynamics.

- Developed force models for launch vehicle guidance systems, ensuring precise trajectory control and optimal mission performance.

- Analyzed and modeled aerodynamic forces on spacecraft during atmospheric reentry, utilizing computational fluid dynamics techniques.

Forcer Maker

- Conceptualized, designed, and implemented complex force models for various aerospace applications, including spacecraft attitude control and launch vehicle guidance.

- Developed advanced algorithms for force modeling, utilizing stateoftheart techniques such as finite element analysis, multibody dynamics, and computational fluid dynamics.

- Validated and verified force models through rigorous testing and simulations, ensuring accuracy and reliability across a wide range of operating conditions.

- Collaborated with multidisciplinary teams to integrate force models into spacecraft and launch vehicle systems, optimizing performance and safety.

Certificates

- Six Sigma Black Belt

- Lean Six Sigma Green Belt

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forcer Maker

- Quantify your accomplishments with specific metrics and results.

- Highlight your expertise in advanced force modeling techniques and software tools.

- Showcase your experience in collaborating with multidisciplinary teams.

- Demonstrate your commitment to accuracy and reliability in force modeling.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Forcer Maker Resume

- Conceptualized, designed, and implemented force models for spacecraft attitude control and launch vehicle guidance systems.

- Developed advanced algorithms for force modeling, utilizing finite element analysis, multibody dynamics, and computational fluid dynamics.

- Validated and verified force models through rigorous testing and simulations, ensuring accuracy and reliability across various operating conditions.

- Collaborated with multidisciplinary teams to integrate force models into spacecraft and launch vehicle systems, optimizing performance and safety.

- Utilized advanced software tools, including MATLAB, Simulink, and ANSYS, to ensure efficient and accurate force modeling.

- Performed detailed force analysis for spacecraft attitude control systems, considering thruster performance, environmental disturbances, and orbital dynamics.

- Developed force models for launch vehicle guidance systems, ensuring precise trajectory control and optimal mission performance.

Frequently Asked Questions (FAQ’s) For Forcer Maker

What is the primary role of a Forcer Maker?

A Forcer Maker is responsible for conceptualizing, designing, and implementing force models for various aerospace applications, such as spacecraft attitude control and launch vehicle guidance.

What skills are essential for a successful Forcer Maker?

Essential skills include proficiency in advanced force modeling algorithms, testing and validation techniques, multidisciplinary collaboration, and specialized software tools such as MATLAB, Simulink, and ANSYS.

What are the major responsibilities of a Forcer Maker?

Key responsibilities involve developing force models, validating their accuracy, collaborating with teams, utilizing software tools, performing force analysis, and optimizing spacecraft and launch vehicle systems.

What qualifications are typically required to become a Forcer Maker?

Typically, a Master’s degree in Mechanical Engineering or a related field is required, along with strong analytical and problem-solving skills.

What are the career prospects for Forcer Makers?

Forcer Makers have opportunities to work in various aerospace organizations, research institutions, and government agencies, contributing to the advancement of spacecraft and launch vehicle technologies.

How can I improve my chances of getting hired as a Forcer Maker?

To enhance your chances, focus on developing a strong educational background, gaining hands-on experience through internships or projects, and building a professional network in the aerospace industry.

What are some of the challenges faced by Forcer Makers?

Common challenges include the complexity of force modeling, the need for high accuracy and reliability, the integration of models into complex systems, and keeping up with advancements in aerospace technologies.