Are you a seasoned Forge Tender seeking a new career path? Discover our professionally built Forge Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

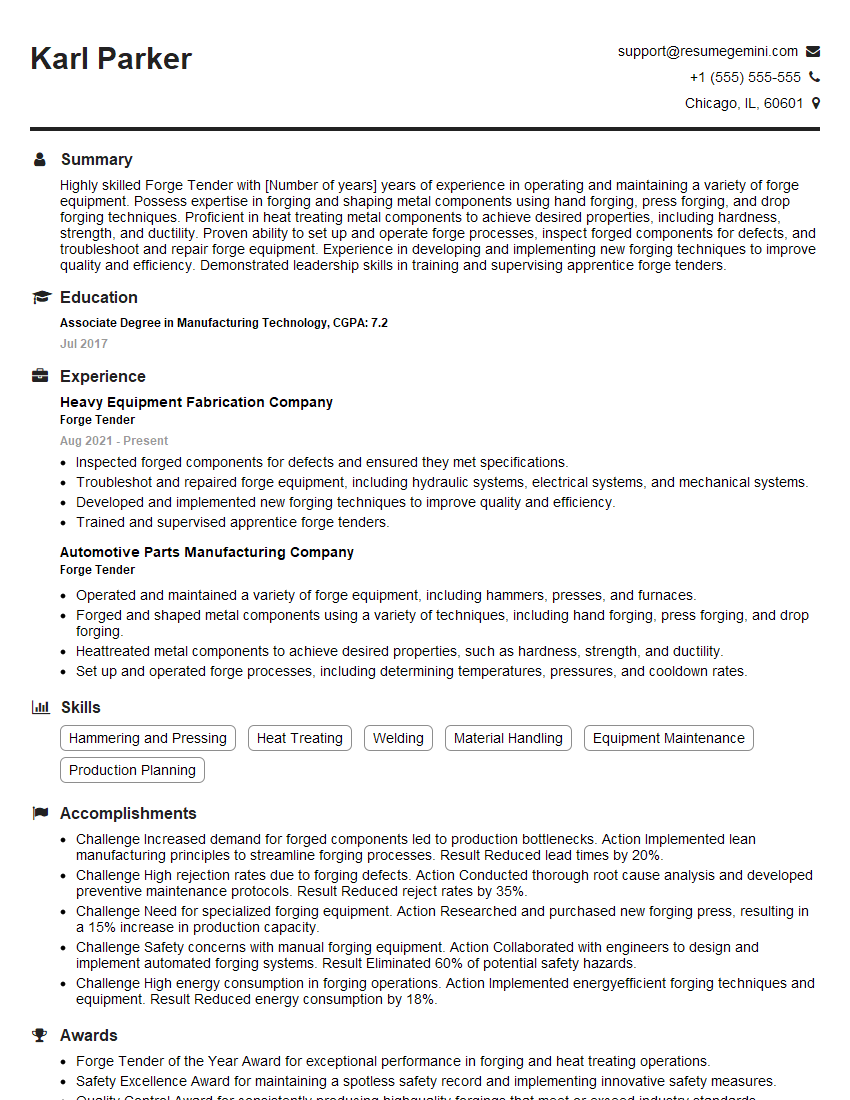

Karl Parker

Forge Tender

Summary

Highly skilled Forge Tender with [Number of years] years of experience in operating and maintaining a variety of forge equipment. Possess expertise in forging and shaping metal components using hand forging, press forging, and drop forging techniques. Proficient in heat treating metal components to achieve desired properties, including hardness, strength, and ductility. Proven ability to set up and operate forge processes, inspect forged components for defects, and troubleshoot and repair forge equipment. Experience in developing and implementing new forging techniques to improve quality and efficiency. Demonstrated leadership skills in training and supervising apprentice forge tenders.

Education

Associate Degree in Manufacturing Technology

July 2017

Skills

- Hammering and Pressing

- Heat Treating

- Welding

- Material Handling

- Equipment Maintenance

- Production Planning

Work Experience

Forge Tender

- Inspected forged components for defects and ensured they met specifications.

- Troubleshot and repaired forge equipment, including hydraulic systems, electrical systems, and mechanical systems.

- Developed and implemented new forging techniques to improve quality and efficiency.

- Trained and supervised apprentice forge tenders.

Forge Tender

- Operated and maintained a variety of forge equipment, including hammers, presses, and furnaces.

- Forged and shaped metal components using a variety of techniques, including hand forging, press forging, and drop forging.

- Heattreated metal components to achieve desired properties, such as hardness, strength, and ductility.

- Set up and operated forge processes, including determining temperatures, pressures, and cooldown rates.

Accomplishments

- Challenge Increased demand for forged components led to production bottlenecks. Action Implemented lean manufacturing principles to streamline forging processes. Result Reduced lead times by 20%.

- Challenge High rejection rates due to forging defects. Action Conducted thorough root cause analysis and developed preventive maintenance protocols. Result Reduced reject rates by 35%.

- Challenge Need for specialized forging equipment. Action Researched and purchased new forging press, resulting in a 15% increase in production capacity.

- Challenge Safety concerns with manual forging equipment. Action Collaborated with engineers to design and implement automated forging systems. Result Eliminated 60% of potential safety hazards.

- Challenge High energy consumption in forging operations. Action Implemented energyefficient forging techniques and equipment. Result Reduced energy consumption by 18%.

Awards

- Forge Tender of the Year Award for exceptional performance in forging and heat treating operations.

- Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety measures.

- Quality Control Award for consistently producing highquality forgings that meet or exceed industry standards.

Certificates

- Occupational Safety and Health Administration (OSHA)

- National Institute for Metalworking Skills (NIMS)

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code (BPVC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forge Tender

- Highlight your skills and experience: Emphasize your proficiency in operating forge equipment, forging techniques, and heat treating processes in your resume.

- Quantify your accomplishments: Whenever possible, use numbers and metrics to demonstrate the impact of your work. For instance, you could mention the percentage of defects you reduced or the efficiency gains you achieved.

- Showcase your knowledge of the industry: Use industry-specific terminology and demonstrate your understanding of forging techniques and metallurgy in your resume.

- Tailor your resume to the job description: Carefully review the job description and tailor your resume to match the specific requirements and keywords.

Essential Experience Highlights for a Strong Forge Tender Resume

- Operate and maintain forge equipment, including hammers, presses, and furnaces

- Forge and shape metal components using various techniques, such as hand forging, press forging, and drop forging

- Heat treat metal components to achieve desired properties, such as hardness, strength, and ductility

- Set up and operate forge processes, including determining temperatures, pressures, and cooldown rates

- Inspect forged components for defects and ensure they meet specifications

- Troubleshoot and repair forge equipment, including hydraulic systems, electrical systems, and mechanical systems

- Develop and implement new forging techniques to improve quality and efficiency

Frequently Asked Questions (FAQ’s) For Forge Tender

What is the role of a Forge Tender?

A Forge Tender is responsible for operating and maintaining forge equipment, shaping metal components, and ensuring the quality of forged products.

What are the key skills required for a Forge Tender?

Key skills include proficiency in operating forge equipment, forging techniques, heat treating processes, and quality control procedures.

What is the typical work environment for a Forge Tender?

Forge Tenders typically work in industrial settings, such as manufacturing plants, foundries, and machine shops.

What are the career advancement opportunities for a Forge Tender?

Experienced Forge Tenders can advance to roles such as Forge Supervisor, Production Manager, or Quality Control Inspector.

What is the job outlook for Forge Tenders?

The job outlook for Forge Tenders is expected to be stable in the coming years due to the ongoing demand for forged metal components in various industries.

What are the safety precautions that Forge Tenders must follow?

Forge Tenders must adhere to strict safety protocols, including wearing protective gear, following proper handling procedures, and maintaining a clean and organized work environment.

What training and education are required to become a Forge Tender?

While formal education is not always required, Forge Tenders typically have an associate degree or certificate in a related field, such as manufacturing technology or metallurgy.