Are you a seasoned Forging Press Operator seeking a new career path? Discover our professionally built Forging Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

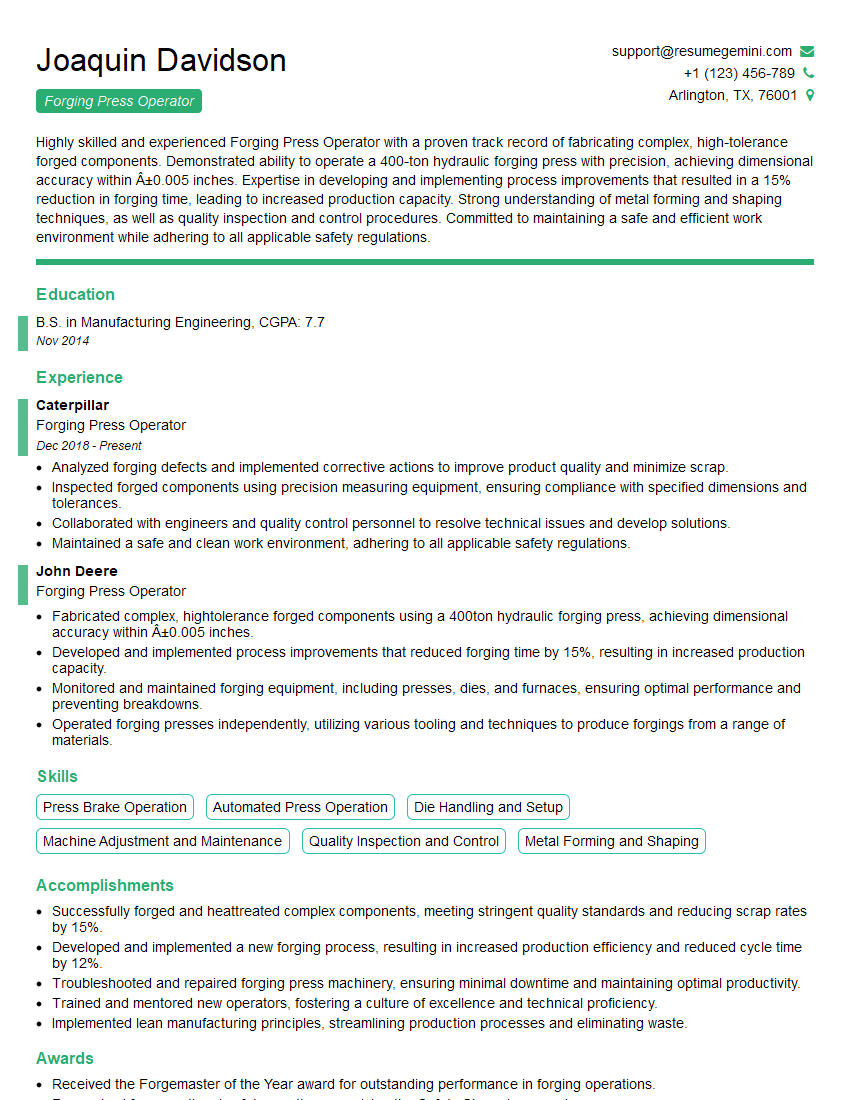

Joaquin Davidson

Forging Press Operator

Summary

Highly skilled and experienced Forging Press Operator with a proven track record of fabricating complex, high-tolerance forged components. Demonstrated ability to operate a 400-ton hydraulic forging press with precision, achieving dimensional accuracy within ±0.005 inches. Expertise in developing and implementing process improvements that resulted in a 15% reduction in forging time, leading to increased production capacity. Strong understanding of metal forming and shaping techniques, as well as quality inspection and control procedures. Committed to maintaining a safe and efficient work environment while adhering to all applicable safety regulations.

Education

B.S. in Manufacturing Engineering

November 2014

Skills

- Press Brake Operation

- Automated Press Operation

- Die Handling and Setup

- Machine Adjustment and Maintenance

- Quality Inspection and Control

- Metal Forming and Shaping

Work Experience

Forging Press Operator

- Analyzed forging defects and implemented corrective actions to improve product quality and minimize scrap.

- Inspected forged components using precision measuring equipment, ensuring compliance with specified dimensions and tolerances.

- Collaborated with engineers and quality control personnel to resolve technical issues and develop solutions.

- Maintained a safe and clean work environment, adhering to all applicable safety regulations.

Forging Press Operator

- Fabricated complex, hightolerance forged components using a 400ton hydraulic forging press, achieving dimensional accuracy within ±0.005 inches.

- Developed and implemented process improvements that reduced forging time by 15%, resulting in increased production capacity.

- Monitored and maintained forging equipment, including presses, dies, and furnaces, ensuring optimal performance and preventing breakdowns.

- Operated forging presses independently, utilizing various tooling and techniques to produce forgings from a range of materials.

Accomplishments

- Successfully forged and heattreated complex components, meeting stringent quality standards and reducing scrap rates by 15%.

- Developed and implemented a new forging process, resulting in increased production efficiency and reduced cycle time by 12%.

- Troubleshooted and repaired forging press machinery, ensuring minimal downtime and maintaining optimal productivity.

- Trained and mentored new operators, fostering a culture of excellence and technical proficiency.

- Implemented lean manufacturing principles, streamlining production processes and eliminating waste.

Awards

- Received the Forgemaster of the Year award for outstanding performance in forging operations.

- Recognized for exceptional safety practices, receiving the Safety Champion award.

- Achieved Six Sigma Black Belt certification, demonstrating expertise in process improvement and quality management.

- Nominated for the Employee of the Year award for exceptional contributions to the forging team.

Certificates

- Certified Forging Press Operator (CFPO)

- International Organization for Standardization (ISO) 9001:2015

- Occupational Safety and Health Administration (OSHA) Safety Training

- American Welding Society (AWS) Welding Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forging Press Operator

- Highlight your experience and skills in operating a 400-ton hydraulic forging press.

- Quantify your accomplishments whenever possible, such as reducing forging time by 15%.

- Demonstrate your knowledge of metal forming and shaping techniques, as well as quality inspection and control procedures.

- Emphasize your commitment to safety and maintaining a clean and efficient work environment.

Essential Experience Highlights for a Strong Forging Press Operator Resume

- Operate and maintain a 400-ton hydraulic forging press to produce high-quality forged components.

- Monitor and maintain forging equipment, including presses, dies, and furnaces, to ensure optimal performance and prevent breakdowns.

- Inspect forged components using precision measuring equipment to ensure compliance with specified dimensions and tolerances.

- Analyze forging defects and implement corrective actions to improve product quality and minimize scrap.

- Collaborate with engineers and quality control personnel to resolve technical issues and develop solutions.

- Adhere to all applicable safety regulations and maintain a safe and clean work environment.

Frequently Asked Questions (FAQ’s) For Forging Press Operator

What is the primary responsibility of a Forging Press Operator?

The primary responsibility of a Forging Press Operator is to operate and maintain a forging press to produce forged components according to specified dimensions and tolerances.

What skills are required to be a successful Forging Press Operator?

To be a successful Forging Press Operator, one should have experience in operating a forging press, knowledge of metal forming and shaping techniques, and expertise in quality inspection and control procedures.

What is the work environment of a Forging Press Operator like?

Forging Press Operators typically work in a manufacturing environment, where they operate heavy machinery and handle hot metal components. They must be able to work in a fast-paced and physically demanding environment.

What are the career prospects for a Forging Press Operator?

With experience and additional training, Forging Press Operators can advance to supervisory roles, such as Foreman or Production Manager.

What safety precautions should Forging Press Operators take?

Forging Press Operators should always wear appropriate safety gear, such as gloves, safety glasses, and earplugs. They should also be aware of the potential hazards of working with heavy machinery and hot metal components.