Are you a seasoned Forging Roll Operator seeking a new career path? Discover our professionally built Forging Roll Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

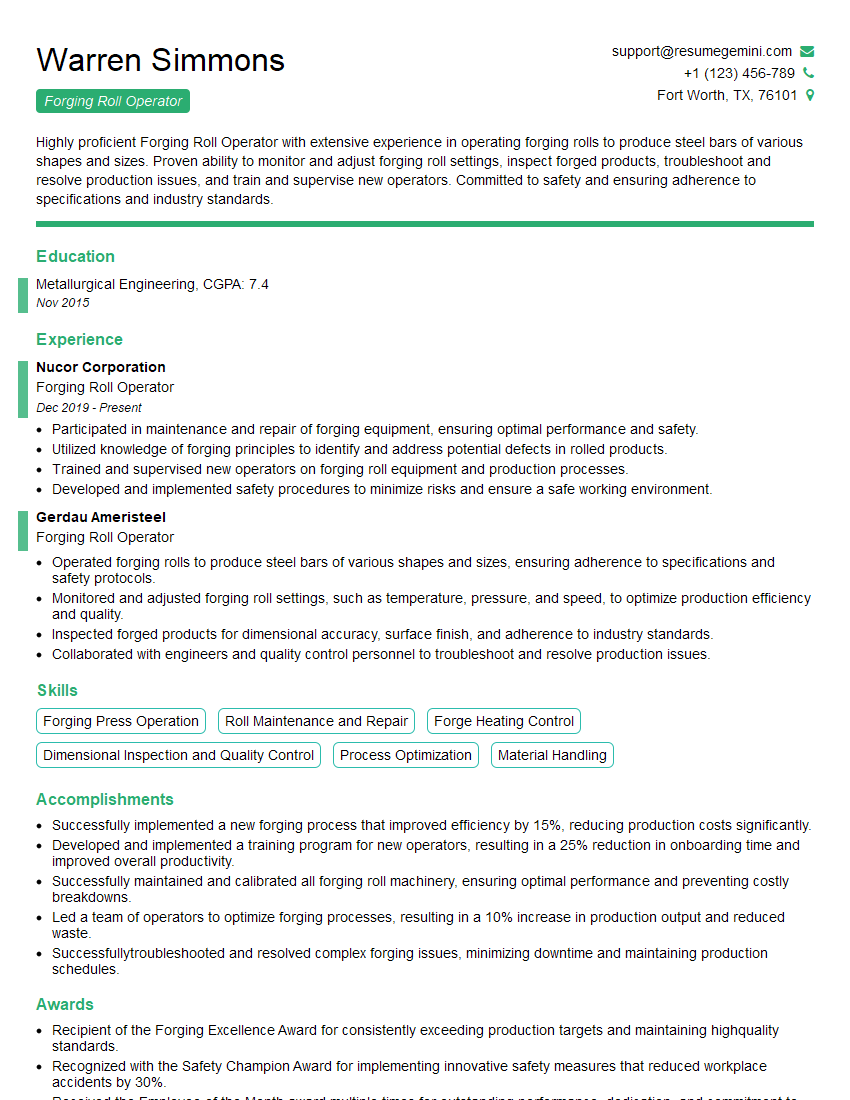

Warren Simmons

Forging Roll Operator

Summary

Highly proficient Forging Roll Operator with extensive experience in operating forging rolls to produce steel bars of various shapes and sizes. Proven ability to monitor and adjust forging roll settings, inspect forged products, troubleshoot and resolve production issues, and train and supervise new operators. Committed to safety and ensuring adherence to specifications and industry standards.

Education

Metallurgical Engineering

November 2015

Skills

- Forging Press Operation

- Roll Maintenance and Repair

- Forge Heating Control

- Dimensional Inspection and Quality Control

- Process Optimization

- Material Handling

Work Experience

Forging Roll Operator

- Participated in maintenance and repair of forging equipment, ensuring optimal performance and safety.

- Utilized knowledge of forging principles to identify and address potential defects in rolled products.

- Trained and supervised new operators on forging roll equipment and production processes.

- Developed and implemented safety procedures to minimize risks and ensure a safe working environment.

Forging Roll Operator

- Operated forging rolls to produce steel bars of various shapes and sizes, ensuring adherence to specifications and safety protocols.

- Monitored and adjusted forging roll settings, such as temperature, pressure, and speed, to optimize production efficiency and quality.

- Inspected forged products for dimensional accuracy, surface finish, and adherence to industry standards.

- Collaborated with engineers and quality control personnel to troubleshoot and resolve production issues.

Accomplishments

- Successfully implemented a new forging process that improved efficiency by 15%, reducing production costs significantly.

- Developed and implemented a training program for new operators, resulting in a 25% reduction in onboarding time and improved overall productivity.

- Successfully maintained and calibrated all forging roll machinery, ensuring optimal performance and preventing costly breakdowns.

- Led a team of operators to optimize forging processes, resulting in a 10% increase in production output and reduced waste.

- Successfullytroubleshooted and resolved complex forging issues, minimizing downtime and maintaining production schedules.

Awards

- Recipient of the Forging Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Recognized with the Safety Champion Award for implementing innovative safety measures that reduced workplace accidents by 30%.

- Received the Employee of the Month award multiple times for outstanding performance, dedication, and commitment to the companys goals.

- Recognized as a Master Forging Roll Operator for exceptional skills and proficiency in operating multiple forging machines simultaneously.

Certificates

- Certified Forging Roll Operator (CFRO)

- National Forging Institute (NFI) certification

- American Society for Metals (ASM) certification

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forging Roll Operator

- Highlight your experience and skills in operating forging rolls, including any specialized knowledge or training.

- Quantify your accomplishments and results, providing specific examples of how you improved production efficiency or product quality.

- Emphasize your commitment to safety and adherence to industry standards.

- Consider including any certifications or professional development courses that demonstrate your knowledge and expertise in forging operations.

Essential Experience Highlights for a Strong Forging Roll Operator Resume

- Operated forging rolls to produce steel bars of various shapes and sizes, ensuring adherence to specifications and safety protocols.

- Monitored and adjusted forging roll settings, such as temperature, pressure, and speed, to optimize production efficiency and quality.

- Inspected forged products for dimensional accuracy, surface finish, and adherence to industry standards.

- Collaborated with engineers and quality control personnel to troubleshoot and resolve production issues.

- Participated in maintenance and repair of forging equipment, ensuring optimal performance and safety.

- Utilized knowledge of forging principles to identify and address potential defects in rolled products.

Frequently Asked Questions (FAQ’s) For Forging Roll Operator

What are the key skills required for a Forging Roll Operator?

Key skills for a Forging Roll Operator include forging press operation, roll maintenance and repair, forge heating control, dimensional inspection and quality control, process optimization, and material handling.

What is the work environment of a Forging Roll Operator like?

Forging Roll Operators typically work in industrial settings, such as steel mills or forging plants. The work environment can be hot, noisy, and physically demanding.

What are the career prospects for a Forging Roll Operator?

Forging Roll Operators with experience and expertise can advance to supervisory or management roles within the forging industry.

What is the average salary for a Forging Roll Operator?

According to Indeed, the average salary for a Forging Roll Operator in the United States is around $65,000 per year.

What are the safety precautions that a Forging Roll Operator must follow?

Forging Roll Operators must follow strict safety protocols, such as wearing appropriate personal protective equipment, being aware of potential hazards, and following established procedures for operating and maintaining equipment.

What are the opportunities for professional development for a Forging Roll Operator?

Forging Roll Operators can enhance their skills and knowledge through on-the-job training, workshops, and industry conferences.

What is the role of a Forging Roll Operator in the production process?

Forging Roll Operators play a crucial role in the production of steel bars by operating forging rolls to shape and size the steel to meet specific requirements.