Are you a seasoned Forming Process Worker seeking a new career path? Discover our professionally built Forming Process Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

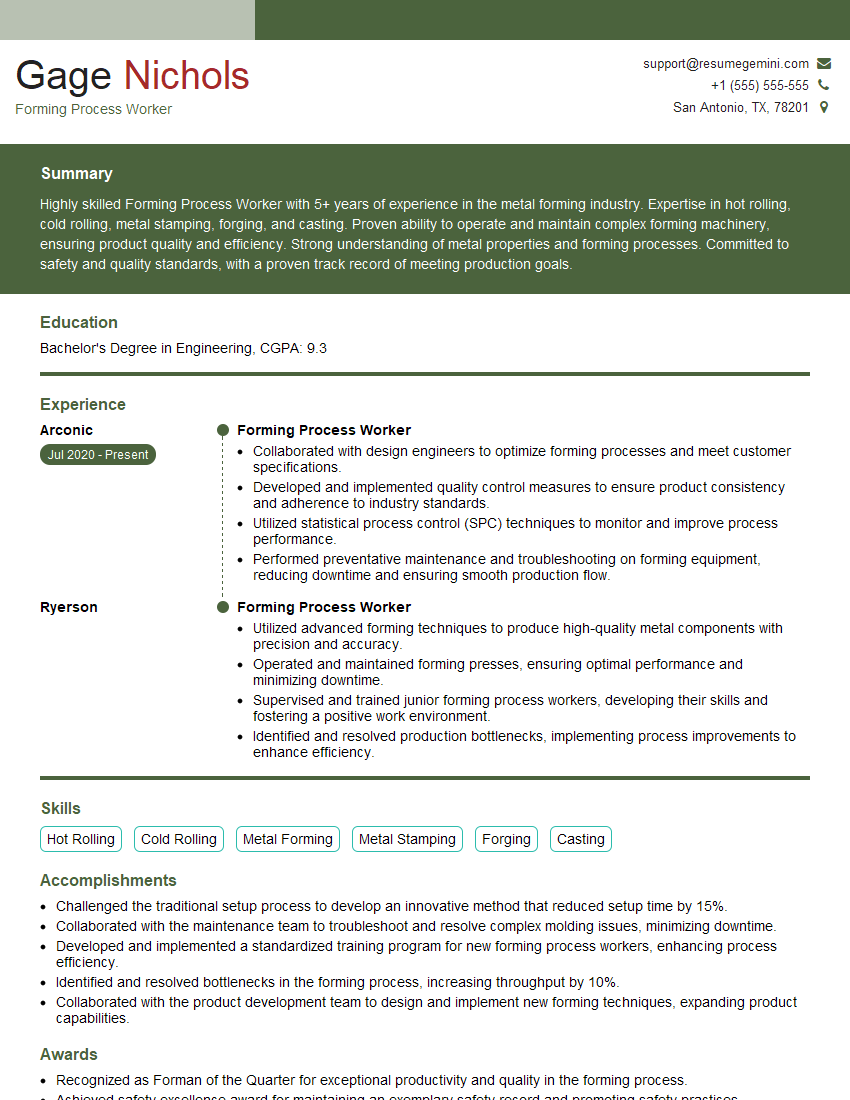

Gage Nichols

Forming Process Worker

Summary

Highly skilled Forming Process Worker with 5+ years of experience in the metal forming industry. Expertise in hot rolling, cold rolling, metal stamping, forging, and casting. Proven ability to operate and maintain complex forming machinery, ensuring product quality and efficiency. Strong understanding of metal properties and forming processes. Committed to safety and quality standards, with a proven track record of meeting production goals.

Education

Bachelor’s Degree in Engineering

June 2016

Skills

- Hot Rolling

- Cold Rolling

- Metal Forming

- Metal Stamping

- Forging

- Casting

Work Experience

Forming Process Worker

- Collaborated with design engineers to optimize forming processes and meet customer specifications.

- Developed and implemented quality control measures to ensure product consistency and adherence to industry standards.

- Utilized statistical process control (SPC) techniques to monitor and improve process performance.

- Performed preventative maintenance and troubleshooting on forming equipment, reducing downtime and ensuring smooth production flow.

Forming Process Worker

- Utilized advanced forming techniques to produce high-quality metal components with precision and accuracy.

- Operated and maintained forming presses, ensuring optimal performance and minimizing downtime.

- Supervised and trained junior forming process workers, developing their skills and fostering a positive work environment.

- Identified and resolved production bottlenecks, implementing process improvements to enhance efficiency.

Accomplishments

- Challenged the traditional setup process to develop an innovative method that reduced setup time by 15%.

- Collaborated with the maintenance team to troubleshoot and resolve complex molding issues, minimizing downtime.

- Developed and implemented a standardized training program for new forming process workers, enhancing process efficiency.

- Identified and resolved bottlenecks in the forming process, increasing throughput by 10%.

- Collaborated with the product development team to design and implement new forming techniques, expanding product capabilities.

Awards

- Recognized as Forman of the Quarter for exceptional productivity and quality in the forming process.

- Achieved safety excellence award for maintaining an exemplary safety record and promoting safety practices.

- Presented with an employee of the year award for contributions to productivity, quality, and teamwork.

- Recognized for optimizing forming parameters, resulting in reduced scrap rates and improved product quality.

Certificates

- Certified Metal Forming Technician (CMFT)

- Certified Production Technician (CPT)

- Occupational Safety and Health Administration (OSHA) Certification

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forming Process Worker

- Highlight your technical skills and experience in the forming industry.

- Quantify your accomplishments whenever possible.

- Use action verbs and specific examples to demonstrate your abilities.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Forming Process Worker Resume

- Operate and maintain forming machinery, including hot rolling mills, cold rolling mills, stamping presses, forging hammers, and casting machines.

- Set up and adjust tooling and dies to meet product specifications.

- Monitor and control forming processes to ensure quality and efficiency.

- Inspect and measure formed products to ensure they meet specifications.

- Troubleshoot and resolve forming problems.

- Maintain a clean and organized work area.

- Follow safety procedures and regulations.

Frequently Asked Questions (FAQ’s) For Forming Process Worker

What is the role of a Forming Process Worker?

Forming Process Workers are responsible for operating and maintaining machinery that forms metal into various shapes and products.

What skills are required to be a Forming Process Worker?

Forming Process Workers typically need a high school diploma or equivalent, as well as experience in the metal forming industry. They should be able to read and interpret blueprints, have a strong understanding of metal properties, and be able to operate and maintain forming machinery.

What is the work environment of a Forming Process Worker like?

Forming Process Workers typically work in manufacturing facilities, where they may be exposed to loud noise, heavy machinery, and hazardous materials.

What is the career outlook for Forming Process Workers?

The career outlook for Forming Process Workers is expected to be good over the next few years, as the demand for metal products continues to grow.

What are the earning potential for Forming Process Workers?

Forming Process Workers can earn a median salary of around $45,000 per year, depending on their experience and location.

What are the benefits of being a Forming Process Worker?

Forming Process Workers can enjoy benefits such as health insurance, paid time off, and a retirement plan.

What are the challenges of being a Forming Process Worker?

Forming Process Workers may face challenges such as working in a noisy and hazardous environment, and having to meet production goals.