Are you a seasoned Foundry Superintendant seeking a new career path? Discover our professionally built Foundry Superintendant Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

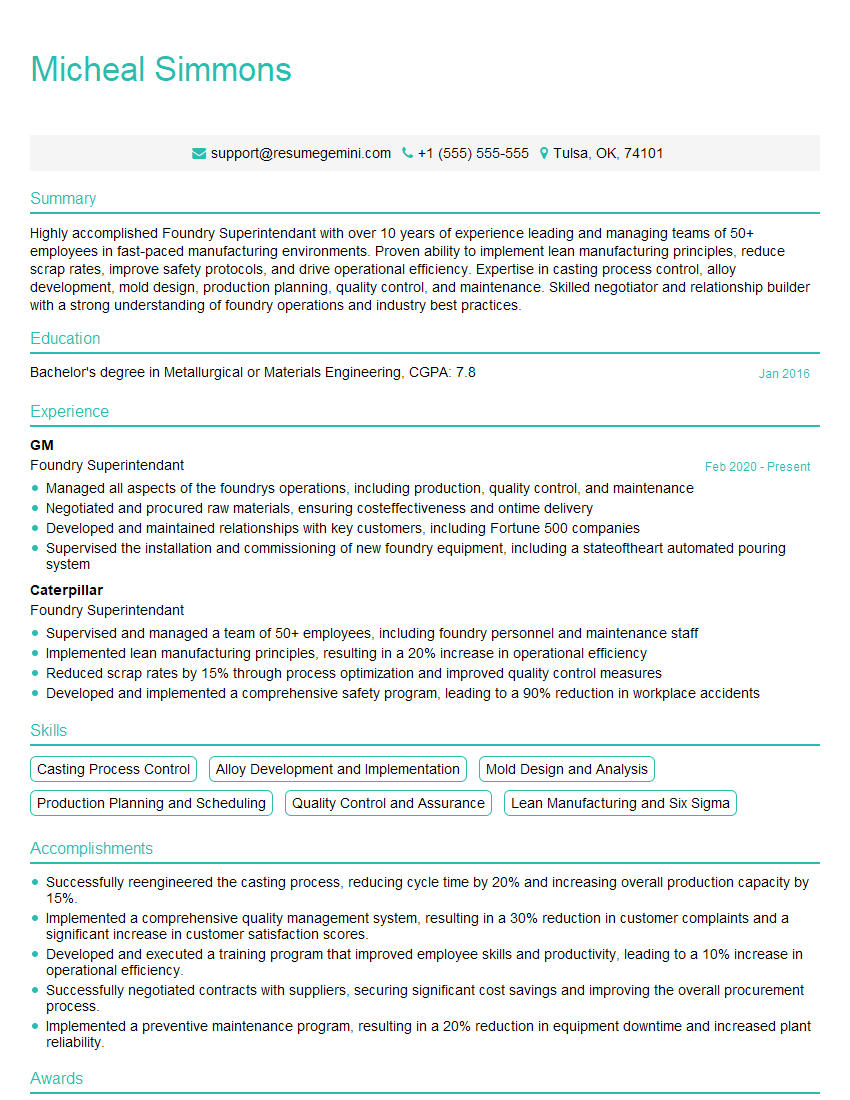

Micheal Simmons

Foundry Superintendant

Summary

Highly accomplished Foundry Superintendant with over 10 years of experience leading and managing teams of 50+ employees in fast-paced manufacturing environments. Proven ability to implement lean manufacturing principles, reduce scrap rates, improve safety protocols, and drive operational efficiency. Expertise in casting process control, alloy development, mold design, production planning, quality control, and maintenance. Skilled negotiator and relationship builder with a strong understanding of foundry operations and industry best practices.

Education

Bachelor’s degree in Metallurgical or Materials Engineering

January 2016

Skills

- Casting Process Control

- Alloy Development and Implementation

- Mold Design and Analysis

- Production Planning and Scheduling

- Quality Control and Assurance

- Lean Manufacturing and Six Sigma

Work Experience

Foundry Superintendant

- Managed all aspects of the foundrys operations, including production, quality control, and maintenance

- Negotiated and procured raw materials, ensuring costeffectiveness and ontime delivery

- Developed and maintained relationships with key customers, including Fortune 500 companies

- Supervised the installation and commissioning of new foundry equipment, including a stateoftheart automated pouring system

Foundry Superintendant

- Supervised and managed a team of 50+ employees, including foundry personnel and maintenance staff

- Implemented lean manufacturing principles, resulting in a 20% increase in operational efficiency

- Reduced scrap rates by 15% through process optimization and improved quality control measures

- Developed and implemented a comprehensive safety program, leading to a 90% reduction in workplace accidents

Accomplishments

- Successfully reengineered the casting process, reducing cycle time by 20% and increasing overall production capacity by 15%.

- Implemented a comprehensive quality management system, resulting in a 30% reduction in customer complaints and a significant increase in customer satisfaction scores.

- Developed and executed a training program that improved employee skills and productivity, leading to a 10% increase in operational efficiency.

- Successfully negotiated contracts with suppliers, securing significant cost savings and improving the overall procurement process.

- Implemented a preventive maintenance program, resulting in a 20% reduction in equipment downtime and increased plant reliability.

Awards

- Recognized with the Foundry Industry Achievement Award for exceptional contributions to casting processes and quality control.

- Received the Safety Excellence Award for implementing innovative safety protocols that significantly reduced workplace accidents.

- Awarded the Lean Manufacturing Excellence Award for successfully implementing LEAN principles, resulting in improved efficiency and reduced production costs.

- Honored with the Foundry Innovator of the Year Award for developing a groundbreaking method for reducing casting defects.

Certificates

- Certified Foundry Superintendent (CFS)

- American Foundry Society (AFS) Member

- American Society for Quality (ASQ) Certified Quality Manager (CQM)

- American Society for Materials (ASM) Fellow

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foundry Superintendant

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your expertise in casting process control, alloy development, and mold design.

- Emphasize your ability to implement lean manufacturing principles and improve operational efficiency.

- Showcase your leadership and management skills, particularly in a high-volume manufacturing environment.

- Demonstrate your commitment to safety and quality control, and your ability to create a positive work culture.

Essential Experience Highlights for a Strong Foundry Superintendant Resume

- Supervise and manage a team of foundry personnel and maintenance staff, ensuring adherence to safety protocols and production goals.

- Implement lean manufacturing principles to streamline operations, reduce waste, and improve productivity.

- Optimize process parameters and implement quality control measures to minimize scrap rates and ensure product quality.

- Develop and execute safety programs to create a safe and compliant work environment for all employees.

- Manage all aspects of foundry operations, including production scheduling, inventory control, and equipment maintenance.

- Negotiate and procure raw materials, ensuring cost-effectiveness and timely delivery.

- Build and maintain relationships with key customers, including Fortune 500 companies, to ensure satisfaction and repeat business.

Frequently Asked Questions (FAQ’s) For Foundry Superintendant

What are the key responsibilities of a Foundry Superintendant?

Foundry Superintendents are responsible for overseeing all aspects of foundry operations, including production planning, quality control, safety, maintenance, and customer relations. They manage teams of employees, implement lean manufacturing principles, and ensure that the foundry meets all production and quality targets.

What are the educational requirements for becoming a Foundry Superintendant?

Most Foundry Superintendents hold a Bachelor’s degree in Metallurgical or Materials Engineering. Some may also have a Master’s degree in Business Administration or a related field.

What are the key skills required for a Foundry Superintendant?

Foundry Superintendents should have a strong understanding of casting processes, alloy development, mold design, and quality control. They should also be proficient in lean manufacturing principles and have excellent leadership and management skills.

What is the career outlook for Foundry Superintendents?

The job outlook for Foundry Superintendents is expected to be good over the next few years. As the manufacturing sector continues to grow, there will be a need for qualified individuals to oversee foundry operations.

What is the average salary for a Foundry Superintendant?

The average salary for a Foundry Superintendant is around $80,000 per year. However, salaries can vary depending on experience, education, and location.

What are the benefits of working as a Foundry Superintendant?

Foundry Superintendents enjoy a number of benefits, including a competitive salary, comprehensive benefits package, and the opportunity to work in a challenging and rewarding environment.

What are the challenges of working as a Foundry Superintendant?

Foundry Superintendents face a number of challenges, including managing a large team of employees, meeting production targets, and ensuring the safety of their workers. They must also be able to adapt to changing market conditions and technological advances.