Are you a seasoned Foundry Tender seeking a new career path? Discover our professionally built Foundry Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

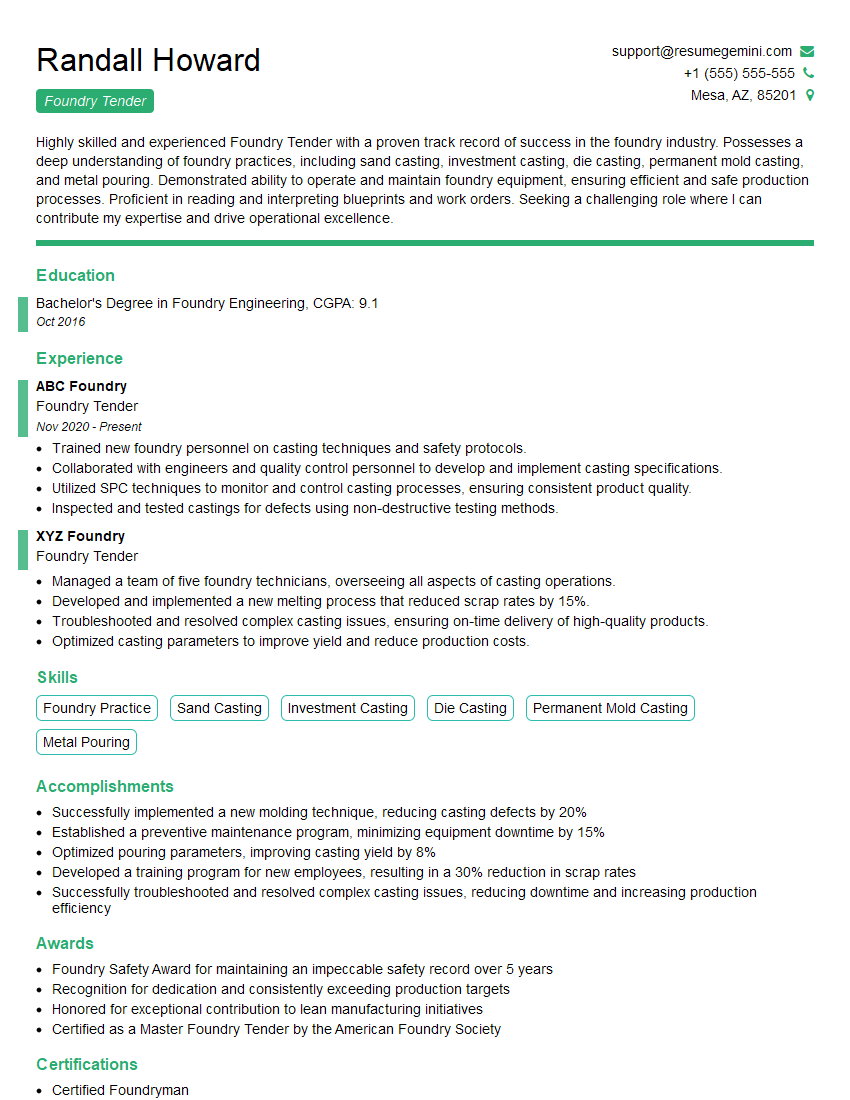

Randall Howard

Foundry Tender

Summary

Highly skilled and experienced Foundry Tender with a proven track record of success in the foundry industry. Possesses a deep understanding of foundry practices, including sand casting, investment casting, die casting, permanent mold casting, and metal pouring. Demonstrated ability to operate and maintain foundry equipment, ensuring efficient and safe production processes. Proficient in reading and interpreting blueprints and work orders. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor’s Degree in Foundry Engineering

October 2016

Skills

- Foundry Practice

- Sand Casting

- Investment Casting

- Die Casting

- Permanent Mold Casting

- Metal Pouring

Work Experience

Foundry Tender

- Trained new foundry personnel on casting techniques and safety protocols.

- Collaborated with engineers and quality control personnel to develop and implement casting specifications.

- Utilized SPC techniques to monitor and control casting processes, ensuring consistent product quality.

- Inspected and tested castings for defects using non-destructive testing methods.

Foundry Tender

- Managed a team of five foundry technicians, overseeing all aspects of casting operations.

- Developed and implemented a new melting process that reduced scrap rates by 15%.

- Troubleshooted and resolved complex casting issues, ensuring on-time delivery of high-quality products.

- Optimized casting parameters to improve yield and reduce production costs.

Accomplishments

- Successfully implemented a new molding technique, reducing casting defects by 20%

- Established a preventive maintenance program, minimizing equipment downtime by 15%

- Optimized pouring parameters, improving casting yield by 8%

- Developed a training program for new employees, resulting in a 30% reduction in scrap rates

- Successfully troubleshooted and resolved complex casting issues, reducing downtime and increasing production efficiency

Awards

- Foundry Safety Award for maintaining an impeccable safety record over 5 years

- Recognition for dedication and consistently exceeding production targets

- Honored for exceptional contribution to lean manufacturing initiatives

- Certified as a Master Foundry Tender by the American Foundry Society

Certificates

- Certified Foundryman

- AFS Safety Certification

- OSHA 30-Hour Safety Training

- ISO 9001:2015 Quality Management

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foundry Tender

- Highlight your technical skills and experience in different foundry practices.

- Quantify your accomplishments with specific metrics and results.

- Showcase your knowledge of safety regulations and adherence to industry standards.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Foundry Tender Resume

- Operate and maintain foundry equipment, including furnaces, molds, and casting machines

- Prepare and mix molding materials, such as sand, binders, and additives

- Pour molten metal into molds and operate casting equipment to produce castings

- Inspect castings for defects and ensure they meet specifications

- Maintain a clean and organized work area, and adhere to all safety regulations

- Troubleshoot and resolve casting issues, and make adjustments to equipment and processes as needed

- Work collaboratively with other foundry personnel to ensure smooth production operations

Frequently Asked Questions (FAQ’s) For Foundry Tender

What are the primary responsibilities of a Foundry Tender?

The primary responsibilities of a Foundry Tender include operating and maintaining foundry equipment, preparing and mixing molding materials, pouring molten metal into molds, inspecting castings for defects, maintaining a clean and organized work area, troubleshooting casting issues, and working collaboratively with other foundry personnel.

What are the essential skills required for a Foundry Tender?

Essential skills for a Foundry Tender include foundry practice, sand casting, investment casting, die casting, permanent mold casting, metal pouring, blueprint reading, and adherence to safety regulations.

What are the qualifications needed to become a Foundry Tender?

Typically, a Foundry Tender requires a high school diploma or equivalent, with additional training or experience in foundry operations. Some employers may prefer candidates with a Bachelor’s Degree in Foundry Engineering or a related field.

What are the career prospects for a Foundry Tender?

Foundry Tenders with experience and expertise can advance to positions such as Foundry Supervisor, Quality Control Manager, or Production Manager. They may also specialize in specific areas of foundry practice, such as investment casting or die casting.

What is the work environment like for a Foundry Tender?

Foundry Tenders typically work in industrial settings, such as foundries or manufacturing plants. The work environment can be hot, noisy, and dusty, and may involve exposure to molten metal and other hazardous materials. Adherence to safety regulations and the use of appropriate protective gear are crucial.

What are the safety precautions that Foundry Tenders should take?

Foundry Tenders should always wear appropriate personal protective equipment, including safety glasses, gloves, and fire-resistant clothing. They should be aware of the hazards associated with molten metal, such as burns and explosions, and follow established safety procedures to minimize risks.