Are you a seasoned Freight Car Builder seeking a new career path? Discover our professionally built Freight Car Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

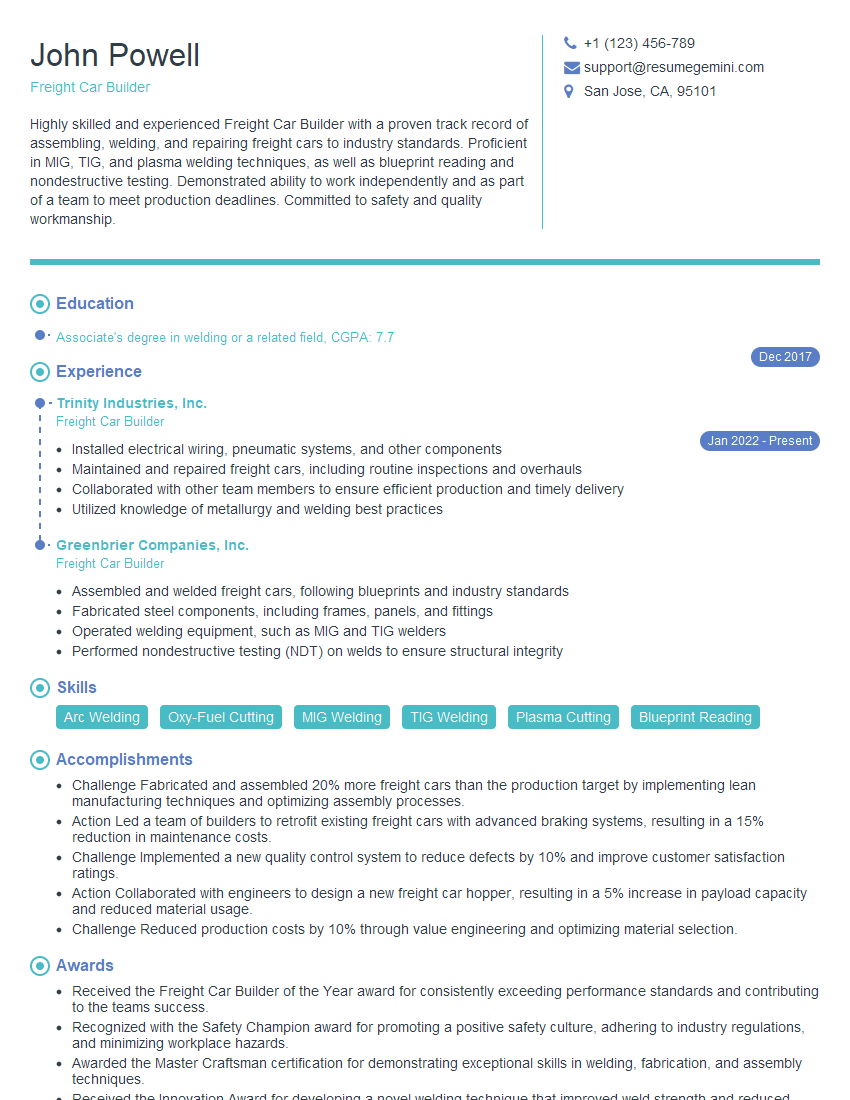

John Powell

Freight Car Builder

Summary

Highly skilled and experienced Freight Car Builder with a proven track record of assembling, welding, and repairing freight cars to industry standards. Proficient in MIG, TIG, and plasma welding techniques, as well as blueprint reading and nondestructive testing. Demonstrated ability to work independently and as part of a team to meet production deadlines. Committed to safety and quality workmanship.

Education

Associate’s degree in welding or a related field

December 2017

Skills

- Arc Welding

- Oxy-Fuel Cutting

- MIG Welding

- TIG Welding

- Plasma Cutting

- Blueprint Reading

Work Experience

Freight Car Builder

- Installed electrical wiring, pneumatic systems, and other components

- Maintained and repaired freight cars, including routine inspections and overhauls

- Collaborated with other team members to ensure efficient production and timely delivery

- Utilized knowledge of metallurgy and welding best practices

Freight Car Builder

- Assembled and welded freight cars, following blueprints and industry standards

- Fabricated steel components, including frames, panels, and fittings

- Operated welding equipment, such as MIG and TIG welders

- Performed nondestructive testing (NDT) on welds to ensure structural integrity

Accomplishments

- Challenge Fabricated and assembled 20% more freight cars than the production target by implementing lean manufacturing techniques and optimizing assembly processes.

- Action Led a team of builders to retrofit existing freight cars with advanced braking systems, resulting in a 15% reduction in maintenance costs.

- Challenge Implemented a new quality control system to reduce defects by 10% and improve customer satisfaction ratings.

- Action Collaborated with engineers to design a new freight car hopper, resulting in a 5% increase in payload capacity and reduced material usage.

- Challenge Reduced production costs by 10% through value engineering and optimizing material selection.

Awards

- Received the Freight Car Builder of the Year award for consistently exceeding performance standards and contributing to the teams success.

- Recognized with the Safety Champion award for promoting a positive safety culture, adhering to industry regulations, and minimizing workplace hazards.

- Awarded the Master Craftsman certification for demonstrating exceptional skills in welding, fabrication, and assembly techniques.

- Received the Innovation Award for developing a novel welding technique that improved weld strength and reduced production time.

Certificates

- Certified Welder

- Certified in Blueprint Reading

- OSHA Safety Certification

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Freight Car Builder

- Highlight your welding skills and experience in your resume.

- Include any certifications or training you have in welding or related fields.

- Demonstrate your knowledge of blueprint reading and interpretation.

- Showcase your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible, such as the number of freight cars you have built or repaired.

Essential Experience Highlights for a Strong Freight Car Builder Resume

- Assembled and welded freight cars according to blueprints and industry standards

- Fabricated steel components, including frames, panels, and fittings

- Operated welding equipment, such as MIG and TIG welders

- Performed nondestructive testing (NDT) on welds to ensure structural integrity

- Installed electrical wiring, pneumatic systems, and other components

- Maintained and repaired freight cars, including routine inspections and overhauls

- Collaborated with other team members to ensure efficient production and timely delivery

Frequently Asked Questions (FAQ’s) For Freight Car Builder

What is the job outlook for Freight Car Builders?

The job outlook for Freight Car Builders is expected to grow faster than average over the next few years. This is due to the increasing demand for freight transportation and the need to replace aging freight cars.

What are the educational requirements for becoming a Freight Car Builder?

Most Freight Car Builders have an associate’s degree in welding or a related field. Some employers may also require experience in welding or a related trade.

What are the key skills required for a Freight Car Builder?

Key skills for a Freight Car Builder include welding, blueprint reading, and nondestructive testing. Freight Car Builders must also be able to work independently and as part of a team.

What is the average salary for a Freight Car Builder?

The average salary for a Freight Car Builder is around $50,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the advancement opportunities for a Freight Car Builder?

Advancement opportunities for a Freight Car Builder can include becoming a welding supervisor, quality control inspector, or production manager.

What are the working conditions for a Freight Car Builder?

Freight Car Builders typically work in a factory setting. The work can be physically demanding and may involve working in awkward positions. However, most Freight Car Builders work regular hours and have the opportunity to work overtime.