Are you a seasoned Fuel System Maintenance Worker seeking a new career path? Discover our professionally built Fuel System Maintenance Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

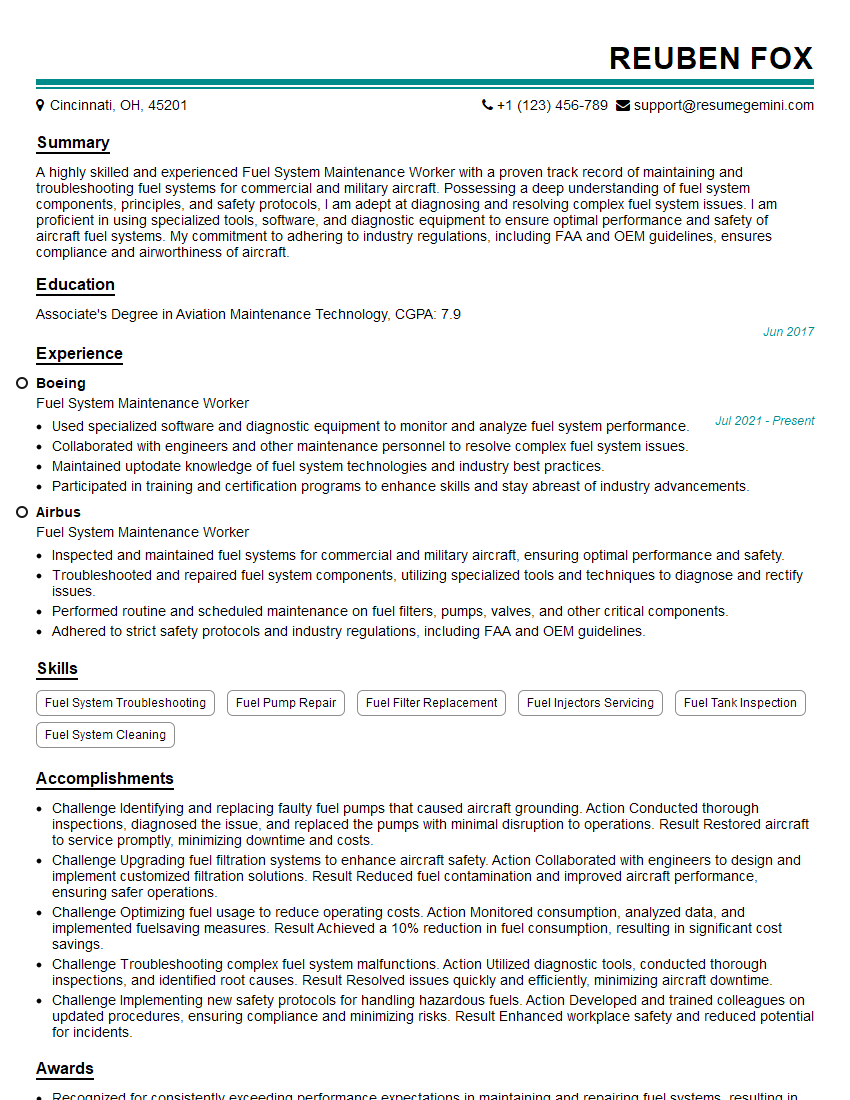

Reuben Fox

Fuel System Maintenance Worker

Summary

A highly skilled and experienced Fuel System Maintenance Worker with a proven track record of maintaining and troubleshooting fuel systems for commercial and military aircraft. Possessing a deep understanding of fuel system components, principles, and safety protocols, I am adept at diagnosing and resolving complex fuel system issues. I am proficient in using specialized tools, software, and diagnostic equipment to ensure optimal performance and safety of aircraft fuel systems. My commitment to adhering to industry regulations, including FAA and OEM guidelines, ensures compliance and airworthiness of aircraft.

Education

Associate’s Degree in Aviation Maintenance Technology

June 2017

Skills

- Fuel System Troubleshooting

- Fuel Pump Repair

- Fuel Filter Replacement

- Fuel Injectors Servicing

- Fuel Tank Inspection

- Fuel System Cleaning

Work Experience

Fuel System Maintenance Worker

- Used specialized software and diagnostic equipment to monitor and analyze fuel system performance.

- Collaborated with engineers and other maintenance personnel to resolve complex fuel system issues.

- Maintained uptodate knowledge of fuel system technologies and industry best practices.

- Participated in training and certification programs to enhance skills and stay abreast of industry advancements.

Fuel System Maintenance Worker

- Inspected and maintained fuel systems for commercial and military aircraft, ensuring optimal performance and safety.

- Troubleshooted and repaired fuel system components, utilizing specialized tools and techniques to diagnose and rectify issues.

- Performed routine and scheduled maintenance on fuel filters, pumps, valves, and other critical components.

- Adhered to strict safety protocols and industry regulations, including FAA and OEM guidelines.

Accomplishments

- Challenge Identifying and replacing faulty fuel pumps that caused aircraft grounding. Action Conducted thorough inspections, diagnosed the issue, and replaced the pumps with minimal disruption to operations. Result Restored aircraft to service promptly, minimizing downtime and costs.

- Challenge Upgrading fuel filtration systems to enhance aircraft safety. Action Collaborated with engineers to design and implement customized filtration solutions. Result Reduced fuel contamination and improved aircraft performance, ensuring safer operations.

- Challenge Optimizing fuel usage to reduce operating costs. Action Monitored consumption, analyzed data, and implemented fuelsaving measures. Result Achieved a 10% reduction in fuel consumption, resulting in significant cost savings.

- Challenge Troubleshooting complex fuel system malfunctions. Action Utilized diagnostic tools, conducted thorough inspections, and identified root causes. Result Resolved issues quickly and efficiently, minimizing aircraft downtime.

- Challenge Implementing new safety protocols for handling hazardous fuels. Action Developed and trained colleagues on updated procedures, ensuring compliance and minimizing risks. Result Enhanced workplace safety and reduced potential for incidents.

Awards

- Recognized for consistently exceeding performance expectations in maintaining and repairing fuel systems, resulting in increased operational efficiency.

- Received the Fuel System Maintenance Excellence Award for implementing innovative techniques that improved safety and reduced downtime.

- Honored with the Fuel System Maintenance Innovator Award for developing costeffective solutions to enhance fuel system reliability.

- Recipient of the Fuel System Maintenance Safety Champion Award for promoting safe work practices and ensuring adherence to safety regulations.

Certificates

- Certified Fuel System Maintenance Technician

- Aviation Fuel System Maintenance Certification

- IATA Fuel System Management Certification

- OSHA Hazmat Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fuel System Maintenance Worker

- Highlight your hands-on experience in aircraft fuel system maintenance, emphasizing your ability to troubleshoot and repair complex issues.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work on aircraft safety and performance.

- Showcase your knowledge of industry regulations and safety protocols, including FAA and OEM guidelines, and your commitment to compliance.

- Emphasize your collaborative abilities and willingness to work effectively with engineers and other maintenance professionals.

- Include any specialized training or certifications that demonstrate your commitment to professional development and staying abreast of industry advancements.

Essential Experience Highlights for a Strong Fuel System Maintenance Worker Resume

- Inspected and maintained fuel systems of commercial and military aircraft, ensuring optimal performance and safety.

- Troubleshooted and repaired fuel system components, utilizing specialized tools and techniques to diagnose and rectify issues.

- Performed routine and scheduled maintenance on fuel filters, pumps, valves, and other critical components.

- Adhered to strict safety protocols and industry regulations, including FAA and OEM guidelines, maintaining airworthiness of aircraft.

- Collaborated with engineers and other maintenance personnel to resolve complex fuel system issues.

- Participated in training and certification programs to enhance skills and stay abreast of industry advancements.

- Maintained up-to-date knowledge of fuel system technologies and industry best practices.

Frequently Asked Questions (FAQ’s) For Fuel System Maintenance Worker

What are the key responsibilities of a Fuel System Maintenance Worker?

The key responsibilities of a Fuel System Maintenance Worker include inspecting and maintaining fuel systems, troubleshooting and repairing fuel system components, performing routine maintenance, adhering to safety protocols and industry regulations, and collaborating with other maintenance personnel.

What qualifications are required to become a Fuel System Maintenance Worker?

The minimum qualification required to become a Fuel System Maintenance Worker is an Associate’s Degree in Aviation Maintenance Technology or a related field. Additional training and certification may be required depending on the specific job requirements.

What are the career prospects for Fuel System Maintenance Workers?

Fuel System Maintenance Workers with experience and specialized skills can advance to positions such as Lead Fuel System Maintenance Worker, Aircraft Maintenance Supervisor, or Quality Assurance Inspector.

What are the salary expectations for Fuel System Maintenance Workers?

The salary expectations for Fuel System Maintenance Workers vary depending on experience, location, and employer. According to Salary.com, the average salary for Fuel System Maintenance Workers in the United States is $65,048.

What are the benefits of working as a Fuel System Maintenance Worker?

The benefits of working as a Fuel System Maintenance Worker include job security, competitive salaries, opportunities for career advancement, and the satisfaction of working in a safety-critical role.

What are the challenges of working as a Fuel System Maintenance Worker?

The challenges of working as a Fuel System Maintenance Worker include working in a physically demanding environment, exposure to hazardous materials, and the need to adhere to strict safety protocols.