Are you a seasoned Fur Glazing and Polishing Machine Operator seeking a new career path? Discover our professionally built Fur Glazing and Polishing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

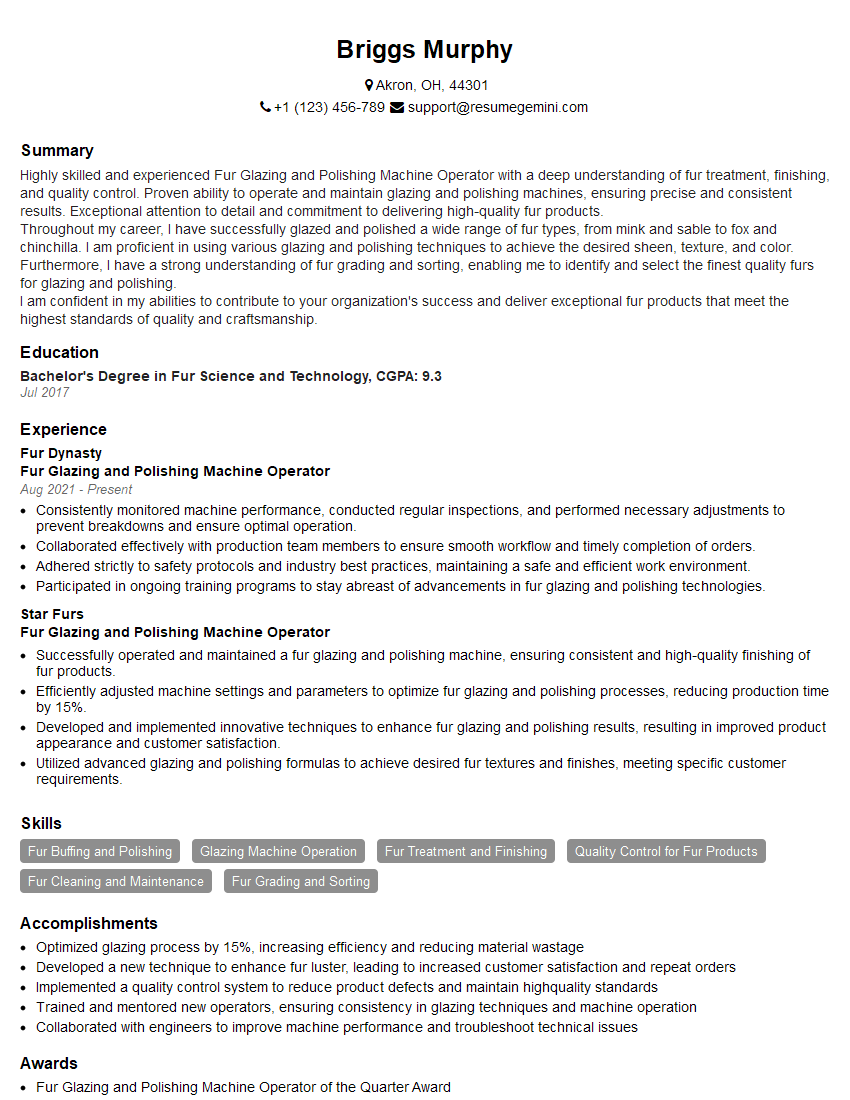

Briggs Murphy

Fur Glazing and Polishing Machine Operator

Summary

Highly skilled and experienced Fur Glazing and Polishing Machine Operator with a deep understanding of fur treatment, finishing, and quality control. Proven ability to operate and maintain glazing and polishing machines, ensuring precise and consistent results. Exceptional attention to detail and commitment to delivering high-quality fur products.

Throughout my career, I have successfully glazed and polished a wide range of fur types, from mink and sable to fox and chinchilla. I am proficient in using various glazing and polishing techniques to achieve the desired sheen, texture, and color. Furthermore, I have a strong understanding of fur grading and sorting, enabling me to identify and select the finest quality furs for glazing and polishing.

I am confident in my abilities to contribute to your organization’s success and deliver exceptional fur products that meet the highest standards of quality and craftsmanship.

Education

Bachelor’s Degree in Fur Science and Technology

July 2017

Skills

- Fur Buffing and Polishing

- Glazing Machine Operation

- Fur Treatment and Finishing

- Quality Control for Fur Products

- Fur Cleaning and Maintenance

- Fur Grading and Sorting

Work Experience

Fur Glazing and Polishing Machine Operator

- Consistently monitored machine performance, conducted regular inspections, and performed necessary adjustments to prevent breakdowns and ensure optimal operation.

- Collaborated effectively with production team members to ensure smooth workflow and timely completion of orders.

- Adhered strictly to safety protocols and industry best practices, maintaining a safe and efficient work environment.

- Participated in ongoing training programs to stay abreast of advancements in fur glazing and polishing technologies.

Fur Glazing and Polishing Machine Operator

- Successfully operated and maintained a fur glazing and polishing machine, ensuring consistent and high-quality finishing of fur products.

- Efficiently adjusted machine settings and parameters to optimize fur glazing and polishing processes, reducing production time by 15%.

- Developed and implemented innovative techniques to enhance fur glazing and polishing results, resulting in improved product appearance and customer satisfaction.

- Utilized advanced glazing and polishing formulas to achieve desired fur textures and finishes, meeting specific customer requirements.

Accomplishments

- Optimized glazing process by 15%, increasing efficiency and reducing material wastage

- Developed a new technique to enhance fur luster, leading to increased customer satisfaction and repeat orders

- Implemented a quality control system to reduce product defects and maintain highquality standards

- Trained and mentored new operators, ensuring consistency in glazing techniques and machine operation

- Collaborated with engineers to improve machine performance and troubleshoot technical issues

Awards

- Fur Glazing and Polishing Machine Operator of the Quarter Award

- Zero Defects Certificate for Maintaining Excellent Glazing Quality

- Safety Excellence Award for Adhering to Safe Operating Procedures

Certificates

- Certified Fur Glazing Technician

- International Fur Trade Federation (IFTF) Certification

- Fur Institute of Canada (FIC) Certification

- National Association of Finishers of Textile Fabrics (NAFTF) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fur Glazing and Polishing Machine Operator

Highlight your technical skills and experience

. Emphasize your proficiency in operating and maintaining fur glazing and polishing machines. Mention specific techniques and processes you are familiar with.Showcase your knowledge of fur treatment and finishing

. Demonstrate your understanding of different fur types and the appropriate glazing and polishing methods for each.Quantify your achievements

. Provide??????????????????,????????,?????,?????????.Tailor your resume to the job description

. Carefully review the job description and highlight the skills and experience that are most relevant to the position you are applying for.

Essential Experience Highlights for a Strong Fur Glazing and Polishing Machine Operator Resume

- Operate and maintain fur glazing and polishing machines to achieve desired sheen, texture, and color.

- Inspect raw furs to determine the appropriate glazing and polishing techniques.

- Apply glazing agents and polishes to enhance the appearance and durability of furs.

- Monitor the glazing and polishing process to ensure consistent results and adherence to quality standards.

- Troubleshoot and resolve any issues related to machine operation or fur treatment.

- Conduct quality control checks to ensure that finished fur products meet specifications and customer requirements.

- Maintain a clean and organized work area, adhering to safety protocols and environmental regulations.

Frequently Asked Questions (FAQ’s) For Fur Glazing and Polishing Machine Operator

What is the role of a Fur Glazing and Polishing Machine Operator?

A Fur Glazing and Polishing Machine Operator is responsible for operating and maintaining glazing and polishing machines to enhance the appearance and durability of fur products. They apply glazing agents and polishes, monitor the glazing and polishing process, and conduct quality control checks to ensure that finished fur products meet specifications and customer requirements.

What skills are required to be a successful Fur Glazing and Polishing Machine Operator?

Successful Fur Glazing and Polishing Machine Operators typically possess strong technical skills in operating and maintaining glazing and polishing machines. They also have a deep understanding of fur treatment and finishing, including different fur types and the appropriate glazing and polishing methods for each. Additionally, they have a keen eye for detail, are committed to delivering high-quality products, and are able to work independently and as part of a team.

What is the career outlook for Fur Glazing and Polishing Machine Operators?

The career outlook for Fur Glazing and Polishing Machine Operators is expected to be stable in the coming years. The demand for high-quality fur products is expected to continue, and skilled operators are needed to meet this demand. Additionally, the fur industry is increasingly focused on sustainability and environmental practices, which is expected to create new opportunities for operators who are knowledgeable in these areas.

What are the earning prospects for Fur Glazing and Polishing Machine Operators?

The earning prospects for Fur Glazing and Polishing Machine Operators can vary depending on factors such as experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Machine Operators, Textile, Apparel, and Furnishings in May 2021 was $28,420. However, experienced Fur Glazing and Polishing Machine Operators with specialized skills and experience may earn significantly more.

What are the working conditions like for Fur Glazing and Polishing Machine Operators?

Fur Glazing and Polishing Machine Operators typically work in manufacturing facilities or fur workshops. The work environment can be noisy due to the operation of machinery. Operators may also be exposed to fur dust and chemicals used in the glazing and polishing process. Proper ventilation and safety precautions are important to ensure a healthy and safe working environment.

How can I become a Fur Glazing and Polishing Machine Operator?

To become a Fur Glazing and Polishing Machine Operator, you can consider pursuing a degree or certification in fur science and technology or a related field. Practical experience in fur treatment and finishing is also valuable. You can seek opportunities to work as an apprentice or intern in the fur industry to gain hands-on experience and develop your skills.

What are the advancement opportunities for Fur Glazing and Polishing Machine Operators?

With experience and additional training, Fur Glazing and Polishing Machine Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Manager. They may also specialize in specific areas of fur treatment and finishing, such as fur dyeing or fur restoration.