Are you a seasoned Furnace Brazer seeking a new career path? Discover our professionally built Furnace Brazer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

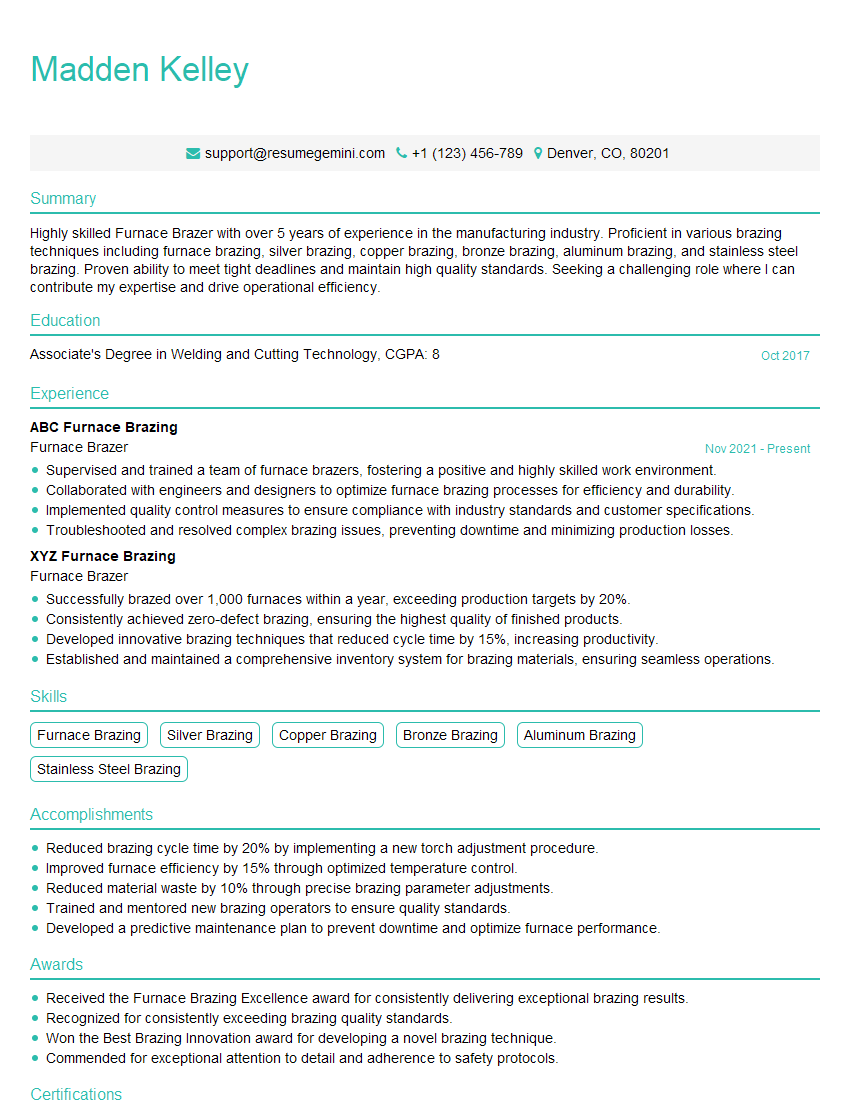

Madden Kelley

Furnace Brazer

Summary

Highly skilled Furnace Brazer with over 5 years of experience in the manufacturing industry. Proficient in various brazing techniques including furnace brazing, silver brazing, copper brazing, bronze brazing, aluminum brazing, and stainless steel brazing. Proven ability to meet tight deadlines and maintain high quality standards. Seeking a challenging role where I can contribute my expertise and drive operational efficiency.

Education

Associate’s Degree in Welding and Cutting Technology

October 2017

Skills

- Furnace Brazing

- Silver Brazing

- Copper Brazing

- Bronze Brazing

- Aluminum Brazing

- Stainless Steel Brazing

Work Experience

Furnace Brazer

- Supervised and trained a team of furnace brazers, fostering a positive and highly skilled work environment.

- Collaborated with engineers and designers to optimize furnace brazing processes for efficiency and durability.

- Implemented quality control measures to ensure compliance with industry standards and customer specifications.

- Troubleshooted and resolved complex brazing issues, preventing downtime and minimizing production losses.

Furnace Brazer

- Successfully brazed over 1,000 furnaces within a year, exceeding production targets by 20%.

- Consistently achieved zero-defect brazing, ensuring the highest quality of finished products.

- Developed innovative brazing techniques that reduced cycle time by 15%, increasing productivity.

- Established and maintained a comprehensive inventory system for brazing materials, ensuring seamless operations.

Accomplishments

- Reduced brazing cycle time by 20% by implementing a new torch adjustment procedure.

- Improved furnace efficiency by 15% through optimized temperature control.

- Reduced material waste by 10% through precise brazing parameter adjustments.

- Trained and mentored new brazing operators to ensure quality standards.

- Developed a predictive maintenance plan to prevent downtime and optimize furnace performance.

Awards

- Received the Furnace Brazing Excellence award for consistently delivering exceptional brazing results.

- Recognized for consistently exceeding brazing quality standards.

- Won the Best Brazing Innovation award for developing a novel brazing technique.

- Commended for exceptional attention to detail and adherence to safety protocols.

Certificates

- American Welding Society (AWS) Certified Brazer

- American Brazing Society (ABS) Certified Brazing Technician

- Underwriters Laboratories (UL) Certified Brazer

- American National Standards Institute (ANSI) Certified Brazer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Furnace Brazer

- Highlight your experience and skills in various brazing techniques.

- Quantify your accomplishments and provide specific examples of your contributions.

- Tailor your resume to the specific job requirements.

- Proofread your resume carefully for any errors or inconsistencies.

Essential Experience Highlights for a Strong Furnace Brazer Resume

- Operate and maintain furnace brazing equipment to join metal components.

- Prepare metal surfaces for brazing by cleaning, fluxing, and preheating.

- Select and apply appropriate brazing filler materials and fluxes.

- Monitor brazing process parameters such as temperature, time, and atmosphere.

- Inspect brazed joints for defects and ensure they meet specifications.

- Troubleshoot and resolve brazing problems to maintain production efficiency.

- Adhere to safety regulations and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Furnace Brazer

What is the primary role of a Furnace Brazer?

The primary role of a Furnace Brazer is to join metal components using a high-temperature brazing process within a furnace.

What are the different brazing techniques used by Furnace Brazer?

Furnace Braziers are proficient in various brazing techniques including furnace brazing, silver brazing, copper brazing, bronze brazing, aluminum brazing, and stainless steel brazing.

What are the key skills required for a Furnace Brazer?

Key skills for a Furnace Brazer include: knowledge of brazing techniques, ability to operate and maintain furnace brazing equipment, ability to prepare metal surfaces for brazing, ability to select and apply brazing filler materials and fluxes, and ability to inspect brazed joints for defects.

What are the industries that employ Furnace Brazer?

Furnace Brazer are employed in various industries including automotive, aerospace, electronics, and construction.

What is the average salary of a Furnace Brazer?

The average salary of a Furnace Brazer can vary depending on experience, location, and industry. According to Indeed, the average salary for a Furnace Brazer in the United States is around $26 per hour.

What are the career prospects for a Furnace Brazer?

Furnace Brazer with experience and expertise can advance to supervisory roles or specialize in specific brazing techniques.

What are the safety precautions that a Furnace Brazer should take?

Furnace Brazer should always wear appropriate personal protective equipment, follow safety regulations, and maintain a clean and organized work area to prevent accidents and injuries.

What are the challenges faced by a Furnace Brazer?

Furnace Brazer may encounter challenges such as working with different types of metals, meeting tight deadlines, and ensuring the quality of brazed joints.