Are you a seasoned Furnace Converter seeking a new career path? Discover our professionally built Furnace Converter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

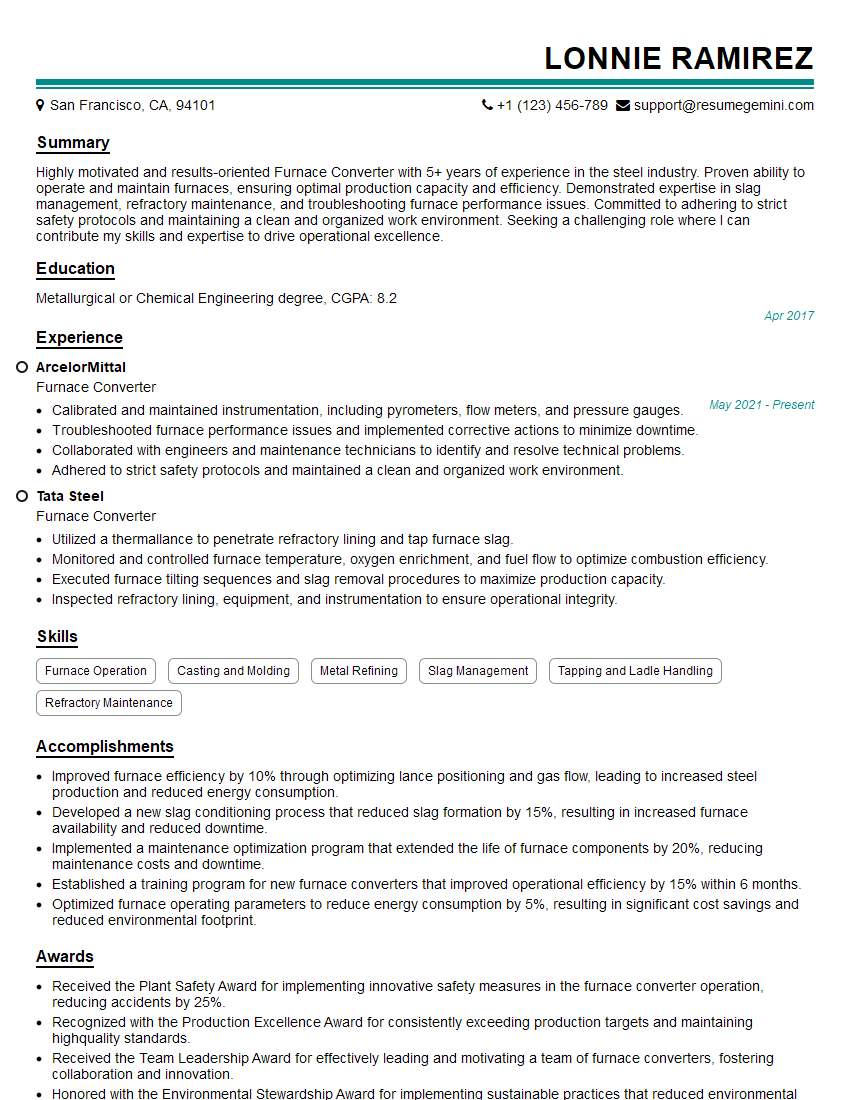

Lonnie Ramirez

Furnace Converter

Summary

Highly motivated and results-oriented Furnace Converter with 5+ years of experience in the steel industry. Proven ability to operate and maintain furnaces, ensuring optimal production capacity and efficiency. Demonstrated expertise in slag management, refractory maintenance, and troubleshooting furnace performance issues. Committed to adhering to strict safety protocols and maintaining a clean and organized work environment. Seeking a challenging role where I can contribute my skills and expertise to drive operational excellence.

Education

Metallurgical or Chemical Engineering degree

April 2017

Skills

- Furnace Operation

- Casting and Molding

- Metal Refining

- Slag Management

- Tapping and Ladle Handling

- Refractory Maintenance

Work Experience

Furnace Converter

- Calibrated and maintained instrumentation, including pyrometers, flow meters, and pressure gauges.

- Troubleshooted furnace performance issues and implemented corrective actions to minimize downtime.

- Collaborated with engineers and maintenance technicians to identify and resolve technical problems.

- Adhered to strict safety protocols and maintained a clean and organized work environment.

Furnace Converter

- Utilized a thermallance to penetrate refractory lining and tap furnace slag.

- Monitored and controlled furnace temperature, oxygen enrichment, and fuel flow to optimize combustion efficiency.

- Executed furnace tilting sequences and slag removal procedures to maximize production capacity.

- Inspected refractory lining, equipment, and instrumentation to ensure operational integrity.

Accomplishments

- Improved furnace efficiency by 10% through optimizing lance positioning and gas flow, leading to increased steel production and reduced energy consumption.

- Developed a new slag conditioning process that reduced slag formation by 15%, resulting in increased furnace availability and reduced downtime.

- Implemented a maintenance optimization program that extended the life of furnace components by 20%, reducing maintenance costs and downtime.

- Established a training program for new furnace converters that improved operational efficiency by 15% within 6 months.

- Optimized furnace operating parameters to reduce energy consumption by 5%, resulting in significant cost savings and reduced environmental footprint.

Awards

- Received the Plant Safety Award for implementing innovative safety measures in the furnace converter operation, reducing accidents by 25%.

- Recognized with the Production Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Received the Team Leadership Award for effectively leading and motivating a team of furnace converters, fostering collaboration and innovation.

- Honored with the Environmental Stewardship Award for implementing sustainable practices that reduced environmental impact and improved air quality around the facility.

Certificates

- Certified Furnace Operator (CFO)

- OSHA Hazwoper 40-Hour Certification

- CPR and First Aid Certification

- AWS Welding Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Furnace Converter

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your expertise in furnace operation, slag management, and refractory maintenance.

- Demonstrate your commitment to safety and maintaining a clean and organized work environment.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Furnace Converter Resume

- Utilized a thermallance to penetrate refractory lining and tap furnace slag.

- Monitored and controlled furnace temperature, oxygen enrichment, and fuel flow to optimize combustion efficiency.

- Executed furnace tilting sequences and slag removal procedures to maximize production capacity.

- Inspected refractory lining, equipment, and instrumentation to ensure operational integrity.

- Calibrated and maintained instrumentation, including pyrometers, flow meters, and pressure gauges.

- Troubleshooted furnace performance issues and implemented corrective actions to minimize downtime.

- Collaborated with engineers and maintenance technicians to identify and resolve technical problems.

Frequently Asked Questions (FAQ’s) For Furnace Converter

What are the key responsibilities of a Furnace Converter?

Furnace Converters are responsible for operating and maintaining furnaces to produce steel. They monitor and control furnace temperature, oxygen enrichment, and fuel flow to optimize combustion efficiency. They also execute furnace tilting sequences and slag removal procedures to maximize production capacity.

What are the qualifications required to become a Furnace Converter?

Furnace Converters typically have a Metallurgical or Chemical Engineering degree. They also have experience in operating and maintaining furnaces, as well as slag management and refractory maintenance.

What are the career prospects for Furnace Converters?

Furnace Converters can advance to positions such as Furnace Supervisor, Production Manager, or Plant Manager. They may also specialize in a particular area of furnace operation, such as refractory maintenance or slag management.

What is the work environment of a Furnace Converter like?

Furnace Converters typically work in a hot and noisy environment. They may also be exposed to hazardous materials, such as molten metal and slag.

What are the safety precautions that Furnace Converters must take?

Furnace Converters must wear protective clothing and equipment, such as hard hats, safety glasses, and gloves. They must also be aware of the potential hazards of working around furnaces and molten metal.

What are the challenges that Furnace Converters face?

Furnace Converters face a number of challenges, including maintaining a consistent furnace temperature, managing slag formation, and preventing refractory damage. They must also be able to troubleshoot furnace performance issues and make repairs as needed.