Are you a seasoned Gear Grinder seeking a new career path? Discover our professionally built Gear Grinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

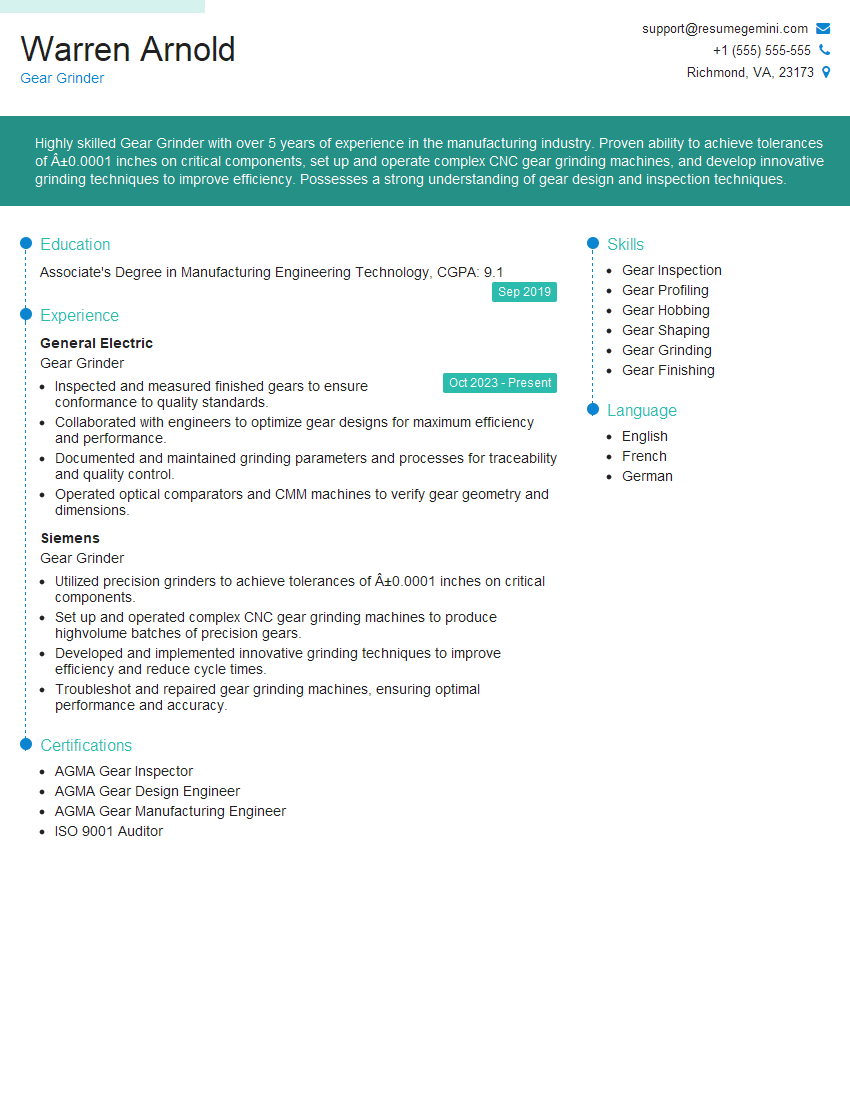

Warren Arnold

Gear Grinder

Summary

Highly skilled Gear Grinder with over 5 years of experience in the manufacturing industry. Proven ability to achieve tolerances of ±0.0001 inches on critical components, set up and operate complex CNC gear grinding machines, and develop innovative grinding techniques to improve efficiency. Possesses a strong understanding of gear design and inspection techniques.

Education

Associate’s Degree in Manufacturing Engineering Technology

September 2019

Skills

- Gear Inspection

- Gear Profiling

- Gear Hobbing

- Gear Shaping

- Gear Grinding

- Gear Finishing

Work Experience

Gear Grinder

- Inspected and measured finished gears to ensure conformance to quality standards.

- Collaborated with engineers to optimize gear designs for maximum efficiency and performance.

- Documented and maintained grinding parameters and processes for traceability and quality control.

- Operated optical comparators and CMM machines to verify gear geometry and dimensions.

Gear Grinder

- Utilized precision grinders to achieve tolerances of ±0.0001 inches on critical components.

- Set up and operated complex CNC gear grinding machines to produce highvolume batches of precision gears.

- Developed and implemented innovative grinding techniques to improve efficiency and reduce cycle times.

- Troubleshot and repaired gear grinding machines, ensuring optimal performance and accuracy.

Certificates

- AGMA Gear Inspector

- AGMA Gear Design Engineer

- AGMA Gear Manufacturing Engineer

- ISO 9001 Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Grinder

- Highlight your skills and experience in precision grinding and gear manufacturing.

- Showcase your knowledge of gear design and inspection techniques.

- Emphasize your ability to troubleshoot and repair gear grinding machines.

- Quantify your accomplishments with specific metrics and examples.

- Tailor your resume to the specific requirements of each job you apply for.

Essential Experience Highlights for a Strong Gear Grinder Resume

- Set up and operated complex CNC gear grinding machines to produce high-volume batches of precision gears.

- Developed and implemented innovative grinding techniques to improve efficiency and reduce cycle times.

- Troubleshot and repaired gear grinding machines, ensuring optimal performance and accuracy.

- Inspected and measured finished gears to ensure conformance to quality standards.

- Collaborated with engineers to optimize gear designs for maximum efficiency and performance.

Frequently Asked Questions (FAQ’s) For Gear Grinder

What is the role of a Gear Grinder?

A Gear Grinder is responsible for producing high-quality gears using specialized grinding machines. Their primary tasks include setting up and operating CNC gear grinding machines, developing grinding techniques, troubleshooting machine issues, and inspecting finished gears to ensure they meet specifications.

What skills are required to be a successful Gear Grinder?

To be a successful Gear Grinder, you should have a strong understanding of gear design and manufacturing processes. You should also be proficient in operating CNC gear grinding machines and have excellent troubleshooting skills. Additionally, you should be able to read and interpret engineering drawings and specifications.

What are the career prospects for Gear Grinders?

Gear Grinders are in high demand in various industries, including automotive, aerospace, and manufacturing. With experience and expertise, you can advance your career to become a Gear Grinder Supervisor or Quality Control Inspector. You can also specialize in different types of gear grinding, such as hobbing, shaping, or finishing.

How can I prepare for a career as a Gear Grinder?

To prepare for a career as a Gear Grinder, you can pursue an Associate’s Degree in Manufacturing Engineering Technology or a related field. You can also gain experience by completing an apprenticeship or working as a Machine Operator in a manufacturing setting. Additionally, you can attend industry workshops and training programs to enhance your skills.

What are the challenges faced by Gear Grinders?

Gear Grinders face several challenges, including working with tight tolerances and meeting demanding production schedules. They must also be able to troubleshoot and repair complex machinery and adapt to new technologies and manufacturing techniques.

What are the safety precautions that Gear Grinders should follow?

Gear Grinders should follow strict safety precautions to prevent accidents and injuries. These include wearing appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. They should also be aware of the potential hazards associated with working with machinery and rotating equipment.