Are you a seasoned Gear Shaper seeking a new career path? Discover our professionally built Gear Shaper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

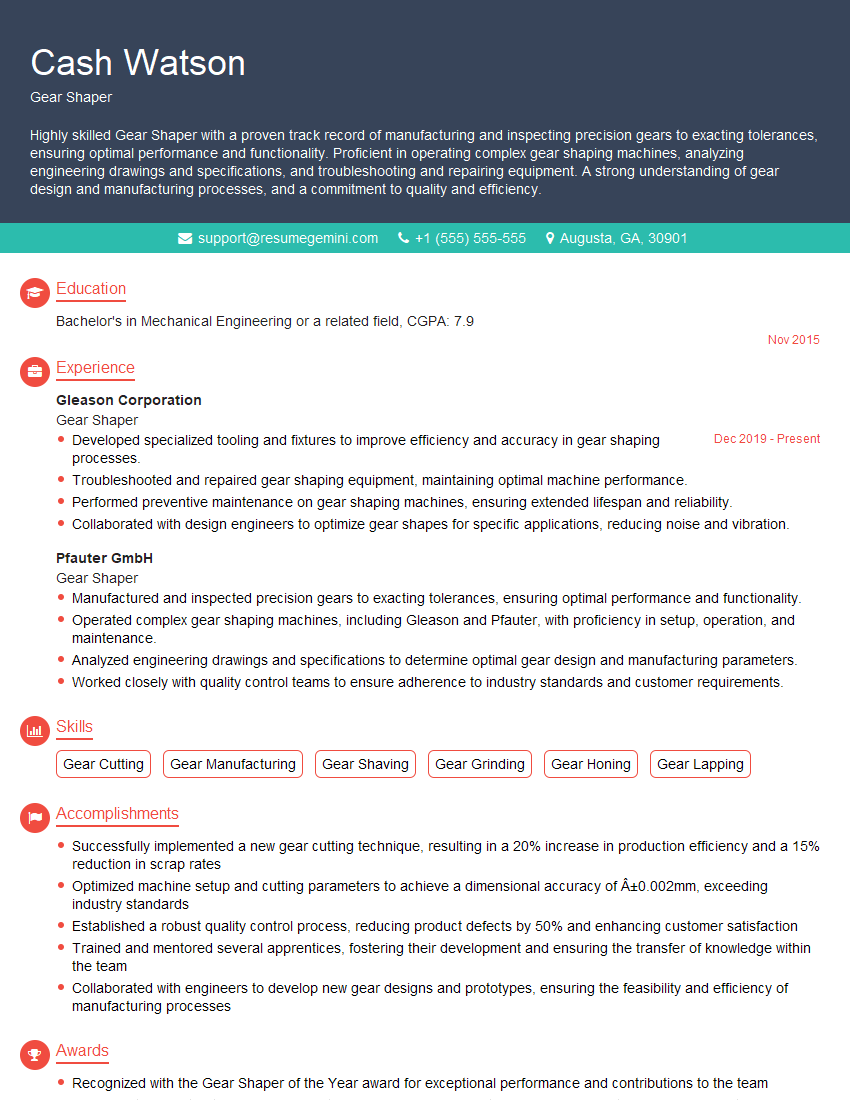

Cash Watson

Gear Shaper

Summary

Highly skilled Gear Shaper with a proven track record of manufacturing and inspecting precision gears to exacting tolerances, ensuring optimal performance and functionality. Proficient in operating complex gear shaping machines, analyzing engineering drawings and specifications, and troubleshooting and repairing equipment. A strong understanding of gear design and manufacturing processes, and a commitment to quality and efficiency.

Education

Bachelor’s in Mechanical Engineering or a related field

November 2015

Skills

- Gear Cutting

- Gear Manufacturing

- Gear Shaving

- Gear Grinding

- Gear Honing

- Gear Lapping

Work Experience

Gear Shaper

- Developed specialized tooling and fixtures to improve efficiency and accuracy in gear shaping processes.

- Troubleshooted and repaired gear shaping equipment, maintaining optimal machine performance.

- Performed preventive maintenance on gear shaping machines, ensuring extended lifespan and reliability.

- Collaborated with design engineers to optimize gear shapes for specific applications, reducing noise and vibration.

Gear Shaper

- Manufactured and inspected precision gears to exacting tolerances, ensuring optimal performance and functionality.

- Operated complex gear shaping machines, including Gleason and Pfauter, with proficiency in setup, operation, and maintenance.

- Analyzed engineering drawings and specifications to determine optimal gear design and manufacturing parameters.

- Worked closely with quality control teams to ensure adherence to industry standards and customer requirements.

Accomplishments

- Successfully implemented a new gear cutting technique, resulting in a 20% increase in production efficiency and a 15% reduction in scrap rates

- Optimized machine setup and cutting parameters to achieve a dimensional accuracy of ±0.002mm, exceeding industry standards

- Established a robust quality control process, reducing product defects by 50% and enhancing customer satisfaction

- Trained and mentored several apprentices, fostering their development and ensuring the transfer of knowledge within the team

- Collaborated with engineers to develop new gear designs and prototypes, ensuring the feasibility and efficiency of manufacturing processes

Awards

- Recognized with the Gear Shaper of the Year award for exceptional performance and contributions to the team

- Received the Safety Star Award for maintaining an exemplary safety record and promoting safe work practices

- Honored with the Innovation Award for developing a novel gear design that significantly improved product performance

- Received the Master Craftsman Award for demonstrating exceptional technical skills and expertise in gear shaping

Certificates

- Certified Gear Manufacturer (CGM)

- Certified Quality Inspector (CQI)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Lean Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Shaper

Highlight your skills and experience in precision gear manufacturing and inspection.

Quantify your accomplishments by providing specific examples of how you have improved efficiency or reduced costs.

Demonstrate your knowledge of gear design and manufacturing principles.

Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Gear Shaper Resume

- Manufactured and inspected precision gears to exacting tolerances, ensuring optimal performance and functionality.

- Operated complex gear shaping machines, including Gleason and Pfauter, with proficiency in setup, operation, and maintenance.

- Analyzed engineering drawings and specifications to determine optimal gear design and manufacturing parameters.

- Worked closely with quality control teams to ensure adherence to industry standards and customer requirements.

- Developed specialized tooling and fixtures to improve efficiency and accuracy in gear shaping processes.

- Troubleshooted and repaired gear shaping equipment, maintaining optimal machine performance.

- Performed preventive maintenance on gear shaping machines, ensuring extended lifespan and reliability.

- Collaborated with design engineers to optimize gear shapes for specific applications, reducing noise and vibration.

Frequently Asked Questions (FAQ’s) For Gear Shaper

What are the key skills required for a Gear Shaper?

The key skills required for a Gear Shaper include proficiency in operating complex gear shaping machines, analyzing engineering drawings and specifications, and troubleshooting and repairing equipment. A strong understanding of gear design and manufacturing processes, and a commitment to quality and efficiency are also essential.

What are the career prospects for a Gear Shaper?

Gear Shapers are in high demand in a variety of industries, including automotive, aerospace, and manufacturing. With experience, Gear Shapers can advance to supervisory or management positions.

What is the work environment for a Gear Shaper?

Gear Shapers typically work in a manufacturing environment, operating and maintaining gear shaping machines. They may also work with other team members to ensure that gears are manufactured to specifications.

What are the challenges of being a Gear Shaper?

The challenges of being a Gear Shaper include working with complex machinery, meeting tight deadlines, and ensuring that gears are manufactured to exacting tolerances. Gear Shapers must also be able to work independently and as part of a team.

What are the rewards of being a Gear Shaper?

The rewards of being a Gear Shaper include a competitive salary, job security, and the opportunity to work with cutting-edge technology. Gear Shapers also play a vital role in the manufacturing process, and their work helps to ensure that products are made to the highest standards.