Are you a seasoned General Maintenance Mechanic seeking a new career path? Discover our professionally built General Maintenance Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

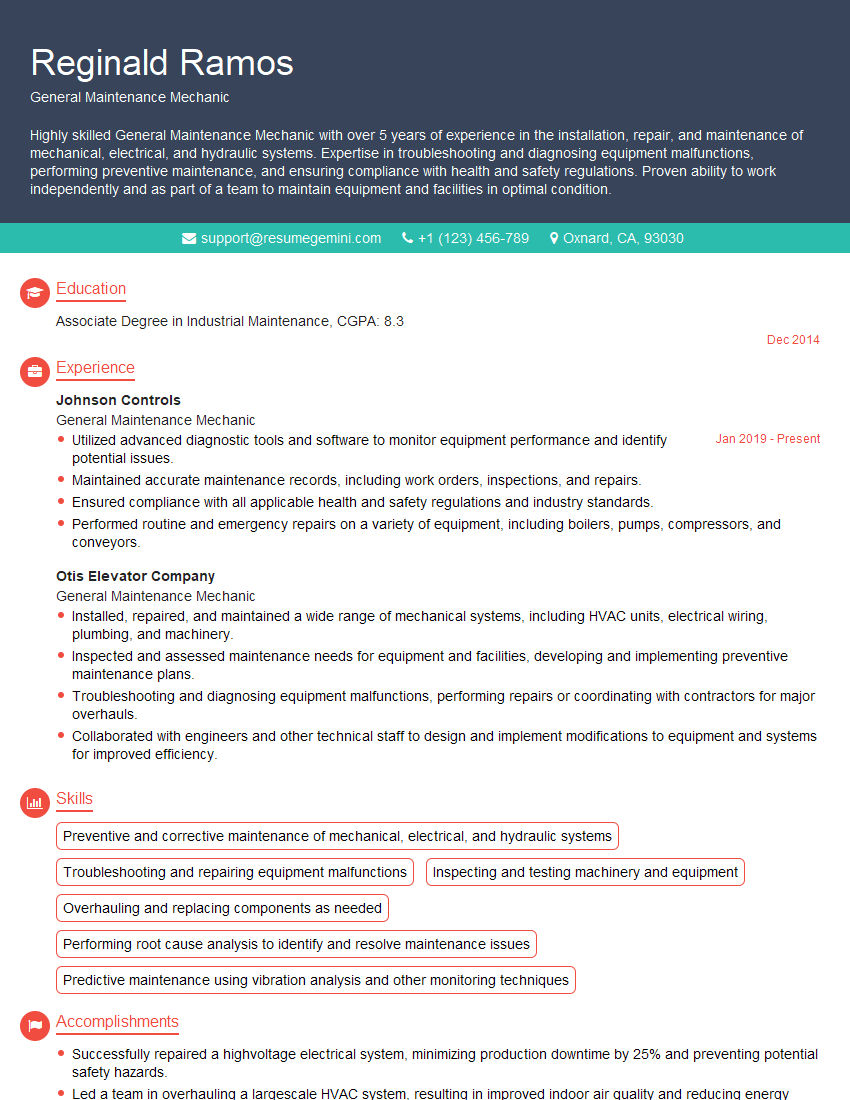

Reginald Ramos

General Maintenance Mechanic

Summary

Highly skilled General Maintenance Mechanic with over 5 years of experience in the installation, repair, and maintenance of mechanical, electrical, and hydraulic systems. Expertise in troubleshooting and diagnosing equipment malfunctions, performing preventive maintenance, and ensuring compliance with health and safety regulations. Proven ability to work independently and as part of a team to maintain equipment and facilities in optimal condition.

Education

Associate Degree in Industrial Maintenance

December 2014

Skills

- Preventive and corrective maintenance of mechanical, electrical, and hydraulic systems

- Troubleshooting and repairing equipment malfunctions

- Inspecting and testing machinery and equipment

- Overhauling and replacing components as needed

- Performing root cause analysis to identify and resolve maintenance issues

- Predictive maintenance using vibration analysis and other monitoring techniques

Work Experience

General Maintenance Mechanic

- Utilized advanced diagnostic tools and software to monitor equipment performance and identify potential issues.

- Maintained accurate maintenance records, including work orders, inspections, and repairs.

- Ensured compliance with all applicable health and safety regulations and industry standards.

- Performed routine and emergency repairs on a variety of equipment, including boilers, pumps, compressors, and conveyors.

General Maintenance Mechanic

- Installed, repaired, and maintained a wide range of mechanical systems, including HVAC units, electrical wiring, plumbing, and machinery.

- Inspected and assessed maintenance needs for equipment and facilities, developing and implementing preventive maintenance plans.

- Troubleshooting and diagnosing equipment malfunctions, performing repairs or coordinating with contractors for major overhauls.

- Collaborated with engineers and other technical staff to design and implement modifications to equipment and systems for improved efficiency.

Accomplishments

- Successfully repaired a highvoltage electrical system, minimizing production downtime by 25% and preventing potential safety hazards.

- Led a team in overhauling a largescale HVAC system, resulting in improved indoor air quality and reducing energy consumption by 12%.

- Developed and implemented a preventive maintenance program, reducing equipment breakdowns by 35% and extending the lifespan of critical assets.

- Troubleshooting and repairing complex mechanical systems, diagnosing root causes and ensuring efficient operations.

- Upgrading and modernizing equipment to meet industry standards and improve overall efficiency.

Awards

- Received the Maintenance Excellence Award for outstanding contributions to the maintenance and repair of critical plant equipment.

- Recognized with the National Safety Councils Safety Achievement Award for maintaining a spotless safety record and implementing innovative safety measures.

- Awarded the Outstanding Maintenance Professional Award by the Chamber of Commerce for exceptional technical skills and dedication to the industry.

- Received the Service Excellence Award for consistently exceeding customer expectations and providing exceptional maintenance support.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Precision Maintenance Technology (PMT) certification

- Certified Maintenance Manager (CMM)

- Certified Plant Maintenance Manager (CPMM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For General Maintenance Mechanic

- Highlight your experience and skills in the specific areas of maintenance that are relevant to the job you’re applying for.

- Use action verbs and quantify your accomplishments whenever possible. For example, instead of saying “Repaired equipment,” say “Repaired over 50 pieces of equipment, reducing downtime by 20%.”

- Proofread your resume carefully for any errors in grammar or spelling.

- Tailor your resume to each job you apply for by highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong General Maintenance Mechanic Resume

- Installed, repaired, and maintained a wide range of mechanical systems, including HVAC units, electrical wiring, plumbing, and machinery.

- Inspected and assessed maintenance needs for equipment and facilities, developing and implementing preventive maintenance plans.

- Troubleshooted and diagnosed equipment malfunctions, performing repairs or coordinating with contractors for major overhauls.

- Collaborated with engineers and other technical staff to design and implement modifications to equipment and systems for improved efficiency.

- Utilized advanced diagnostic tools and software to monitor equipment performance and identify potential issues.

- Maintained accurate maintenance records, including work orders, inspections, and repairs.

- Ensured compliance with all applicable health and safety regulations and industry standards.

Frequently Asked Questions (FAQ’s) For General Maintenance Mechanic

What are the key skills and qualifications required to become a General Maintenance Mechanic?

The key skills and qualifications required to become a General Maintenance Mechanic include a strong understanding of mechanical, electrical, and hydraulic systems, as well as troubleshooting and repair skills. Additionally, General Maintenance Mechanics must be able to read and interpret blueprints and schematics, and have a working knowledge of safety regulations and industry standards.

What are the typical job responsibilities of a General Maintenance Mechanic?

The typical job responsibilities of a General Maintenance Mechanic include installing, repairing, and maintaining mechanical, electrical, and hydraulic systems. They also inspect and assess maintenance needs for equipment and facilities, develop and implement preventive maintenance plans, and troubleshoot and diagnose equipment malfunctions.

What is the average salary for a General Maintenance Mechanic?

The average salary for a General Maintenance Mechanic in the United States is around $35,000 per year.

What are the career prospects for General Maintenance Mechanics?

The career prospects for General Maintenance Mechanics are good. The demand for skilled maintenance professionals is expected to grow in the coming years as more businesses and organizations realize the importance of maintaining their equipment and facilities in good working order.

What are the educational requirements to become a General Maintenance Mechanic?

The educational requirements to become a General Maintenance Mechanic typically include a high school diploma or equivalent, as well as some post-secondary education in a related field such as industrial maintenance or mechanical engineering.

What are the certification requirements to become a General Maintenance Mechanic?

There are no specific certification requirements to become a General Maintenance Mechanic, but some employers may prefer candidates who have obtained certification from a recognized organization such as the National Institute for Certification in Engineering Technologies (NICET) or the International Association of Certified Home Inspectors (InterNACHI).

What are the soft skills required to become a General Maintenance Mechanic?

The soft skills required to become a General Maintenance Mechanic include communication, teamwork, problem-solving, and critical thinking skills. They must also be able to work independently and as part of a team, and be able to follow instructions and work safely.