Are you a seasoned Gyroscopic Instrument Mechanic seeking a new career path? Discover our professionally built Gyroscopic Instrument Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

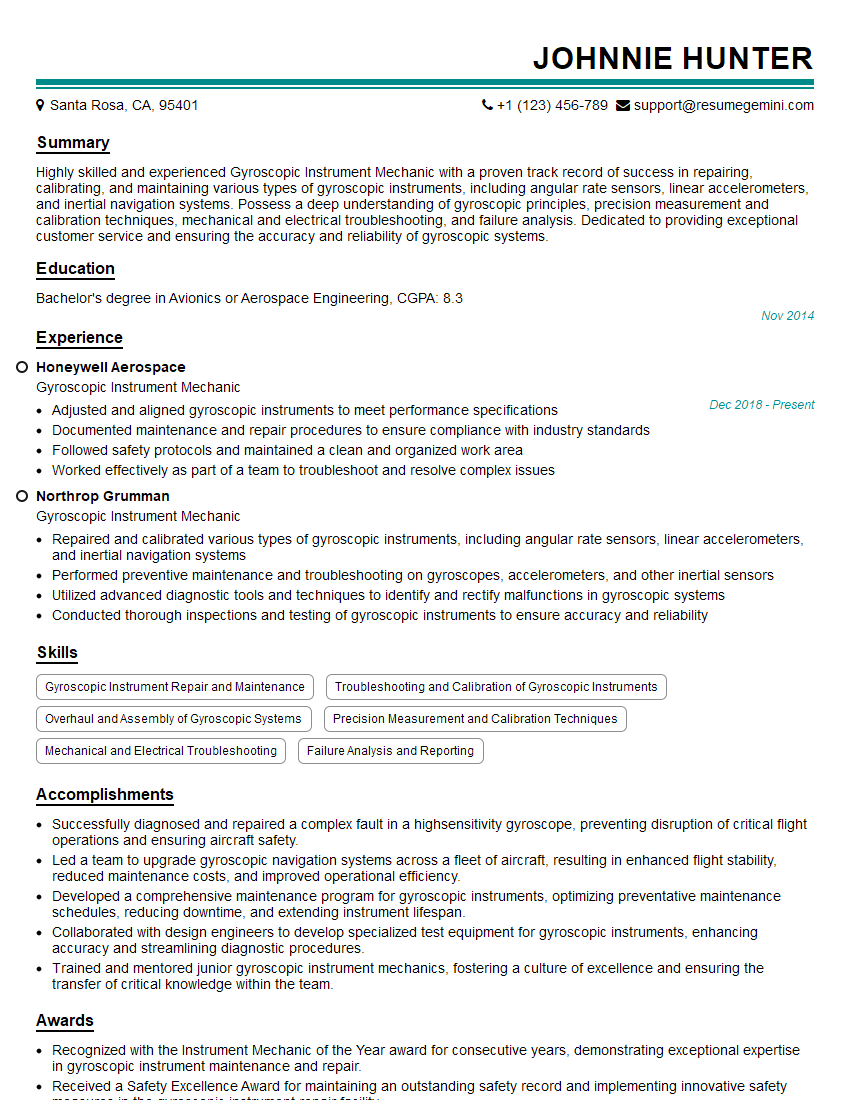

Johnnie Hunter

Gyroscopic Instrument Mechanic

Summary

Highly skilled and experienced Gyroscopic Instrument Mechanic with a proven track record of success in repairing, calibrating, and maintaining various types of gyroscopic instruments, including angular rate sensors, linear accelerometers, and inertial navigation systems. Possess a deep understanding of gyroscopic principles, precision measurement and calibration techniques, mechanical and electrical troubleshooting, and failure analysis. Dedicated to providing exceptional customer service and ensuring the accuracy and reliability of gyroscopic systems.

Education

Bachelor’s degree in Avionics or Aerospace Engineering

November 2014

Skills

- Gyroscopic Instrument Repair and Maintenance

- Troubleshooting and Calibration of Gyroscopic Instruments

- Overhaul and Assembly of Gyroscopic Systems

- Precision Measurement and Calibration Techniques

- Mechanical and Electrical Troubleshooting

- Failure Analysis and Reporting

Work Experience

Gyroscopic Instrument Mechanic

- Adjusted and aligned gyroscopic instruments to meet performance specifications

- Documented maintenance and repair procedures to ensure compliance with industry standards

- Followed safety protocols and maintained a clean and organized work area

- Worked effectively as part of a team to troubleshoot and resolve complex issues

Gyroscopic Instrument Mechanic

- Repaired and calibrated various types of gyroscopic instruments, including angular rate sensors, linear accelerometers, and inertial navigation systems

- Performed preventive maintenance and troubleshooting on gyroscopes, accelerometers, and other inertial sensors

- Utilized advanced diagnostic tools and techniques to identify and rectify malfunctions in gyroscopic systems

- Conducted thorough inspections and testing of gyroscopic instruments to ensure accuracy and reliability

Accomplishments

- Successfully diagnosed and repaired a complex fault in a highsensitivity gyroscope, preventing disruption of critical flight operations and ensuring aircraft safety.

- Led a team to upgrade gyroscopic navigation systems across a fleet of aircraft, resulting in enhanced flight stability, reduced maintenance costs, and improved operational efficiency.

- Developed a comprehensive maintenance program for gyroscopic instruments, optimizing preventative maintenance schedules, reducing downtime, and extending instrument lifespan.

- Collaborated with design engineers to develop specialized test equipment for gyroscopic instruments, enhancing accuracy and streamlining diagnostic procedures.

- Trained and mentored junior gyroscopic instrument mechanics, fostering a culture of excellence and ensuring the transfer of critical knowledge within the team.

Awards

- Recognized with the Instrument Mechanic of the Year award for consecutive years, demonstrating exceptional expertise in gyroscopic instrument maintenance and repair.

- Received a Safety Excellence Award for maintaining an outstanding safety record and implementing innovative safety measures in the gyroscopic instrument repair facility.

- Honored with the Technical Innovation Award for developing a novel approach to calibrate gyroscopic instruments, significantly improving accuracy and reducing turnaround time.

Certificates

- Certified Gyroscopic Instrument Mechanic

- FAA Certified Aircraft Instrument Mechanic

- AS9100D Certification

- ISO 9001:2015 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gyroscopic Instrument Mechanic

- Highlight your skills and experience with gyroscopic instruments, especially your ability to troubleshoot and repair complex issues.

- Showcase your understanding of gyroscopic principles and precision measurement techniques.

- Provide specific examples of projects or tasks you have completed that demonstrate your expertise.

- Emphasize your attention to detail and ability to work independently and as part of a team.

- Quantify your accomplishments and results, such as the number of gyroscopic instruments you have repaired or the percentage improvement in accuracy achieved after calibration.

Essential Experience Highlights for a Strong Gyroscopic Instrument Mechanic Resume

- Repair and calibrate gyroscopic instruments, such as angular rate sensors, linear accelerometers, and inertial navigation systems

- Perform preventive maintenance and troubleshooting on gyroscopes, accelerometers, and other inertial sensors

- Utilize advanced diagnostic tools and techniques to identify and rectify malfunctions in gyroscopic systems

- Conduct thorough inspections and testing of gyroscopic instruments to ensure accuracy and reliability

- Adjust and align gyroscopic instruments to meet performance specifications

- Document maintenance and repair procedures to ensure compliance with industry standards

- Follow safety protocols and maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Gyroscopic Instrument Mechanic

What are the primary responsibilities of a Gyroscopic Instrument Mechanic?

Gyroscopic Instrument Mechanics are responsible for repairing, calibrating, and maintaining gyroscopic instruments, which are used in various industries, including aerospace, defense, and manufacturing. They inspect and test these instruments to ensure their accuracy and reliability. They also troubleshoot and repair any malfunctions in these systems.

What skills and qualifications are required to become a Gyroscopic Instrument Mechanic?

Gyroscopic Instrument Mechanics typically have a background in electronics, mechanics, or a related field. They should have a strong understanding of gyroscopic principles, precision measurement techniques, and mechanical and electrical troubleshooting. They should also be able to work independently and as part of a team.

What are the career prospects for Gyroscopic Instrument Mechanics?

Gyroscopic Instrument Mechanics are in high demand due to the increasing use of gyroscopic instruments in various industries. They can find employment in aerospace, defense, manufacturing, and other industries that rely on precision measurement and control systems.

What are the earning prospects for Gyroscopic Instrument Mechanics?

The salary of a Gyroscopic Instrument Mechanic depends on their experience, skills, and the industry they work in. According to the U.S. Bureau of Labor Statistics, the median annual salary for Precision Instrument and Equipment Repairers, which includes Gyroscopic Instrument Mechanics, was $56,830 in May 2021.

What are the advancement opportunities for Gyroscopic Instrument Mechanics?

Gyroscopic Instrument Mechanics can advance their careers by specializing in a particular area, such as aerospace or defense, or by moving into management or supervisory roles. They can also pursue additional education or training to enhance their skills and knowledge.

What are the challenges faced by Gyroscopic Instrument Mechanics?

Gyroscopic Instrument Mechanics may face challenges due to the precision and sensitivity of the instruments they work with. They must be able to work independently and pay close attention to detail. They may also work in demanding environments, such as on aircraft or in manufacturing facilities.