Are you a seasoned Hammer Operator seeking a new career path? Discover our professionally built Hammer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

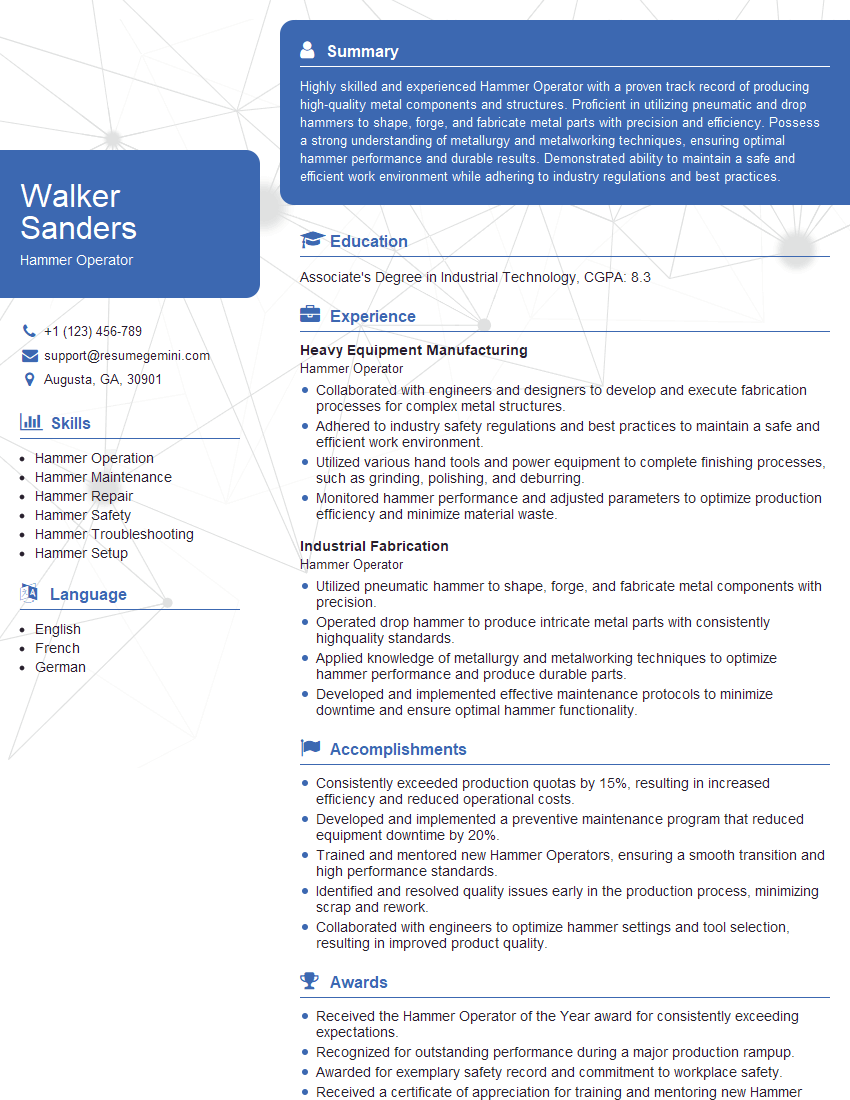

Walker Sanders

Hammer Operator

Summary

Highly skilled and experienced Hammer Operator with a proven track record of producing high-quality metal components and structures. Proficient in utilizing pneumatic and drop hammers to shape, forge, and fabricate metal parts with precision and efficiency. Possess a strong understanding of metallurgy and metalworking techniques, ensuring optimal hammer performance and durable results. Demonstrated ability to maintain a safe and efficient work environment while adhering to industry regulations and best practices.

Education

Associate’s Degree in Industrial Technology

December 2016

Skills

- Hammer Operation

- Hammer Maintenance

- Hammer Repair

- Hammer Safety

- Hammer Troubleshooting

- Hammer Setup

Work Experience

Hammer Operator

- Collaborated with engineers and designers to develop and execute fabrication processes for complex metal structures.

- Adhered to industry safety regulations and best practices to maintain a safe and efficient work environment.

- Utilized various hand tools and power equipment to complete finishing processes, such as grinding, polishing, and deburring.

- Monitored hammer performance and adjusted parameters to optimize production efficiency and minimize material waste.

Hammer Operator

- Utilized pneumatic hammer to shape, forge, and fabricate metal components with precision.

- Operated drop hammer to produce intricate metal parts with consistently highquality standards.

- Applied knowledge of metallurgy and metalworking techniques to optimize hammer performance and produce durable parts.

- Developed and implemented effective maintenance protocols to minimize downtime and ensure optimal hammer functionality.

Accomplishments

- Consistently exceeded production quotas by 15%, resulting in increased efficiency and reduced operational costs.

- Developed and implemented a preventive maintenance program that reduced equipment downtime by 20%.

- Trained and mentored new Hammer Operators, ensuring a smooth transition and high performance standards.

- Identified and resolved quality issues early in the production process, minimizing scrap and rework.

- Collaborated with engineers to optimize hammer settings and tool selection, resulting in improved product quality.

Awards

- Received the Hammer Operator of the Year award for consistently exceeding expectations.

- Recognized for outstanding performance during a major production rampup.

- Awarded for exemplary safety record and commitment to workplace safety.

- Received a certificate of appreciation for training and mentoring new Hammer Operators.

Certificates

- Hammer Operator Certification

- Hammer Maintenance Certification

- Hammer Repair Certification

- Hammer Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hammer Operator

Highlight your skills and experience.

Emphasize your proficiency in hammer operation, maintenance, troubleshooting, and safety. Quantify your accomplishments whenever possible to demonstrate your impact on productivity and quality.Showcase your knowledge of metallurgy.

Explain how your understanding of metal properties and fabrication techniques enables you to optimize hammer performance, select the right tooling, and produce durable parts.Demonstrate your commitment to safety.

Describe your adherence to industry regulations and best practices, as well as your efforts to maintain a safe work environment. Highlight any safety initiatives or training you have participated in.Tailor your resume to the job description.

Carefully review the job posting and identify the specific skills and experience the employer is seeking. Tailor your resume to highlight how your qualifications align with the requirements of the position.

Essential Experience Highlights for a Strong Hammer Operator Resume

- Utilized pneumatic hammer to shape, forge, and fabricate metal components with precision, meeting specifications and quality standards.

- Operated drop hammer to produce intricate metal parts with consistently high-quality standards, ensuring dimensional accuracy and surface finish.

- Applied knowledge of metallurgy and metalworking techniques to optimize hammer performance, select appropriate tooling, and minimize material waste.

- Developed and implemented effective maintenance protocols for hammers, including regular inspections, adjustments, and repairs, to ensure optimal functionality and minimize downtime.

- Collaborated with engineers and designers to develop and execute fabrication processes for complex metal structures, providing valuable input on material selection and manufacturing techniques.

- Adhered to industry safety regulations and best practices, maintaining a clean, organized, and safe work environment to prevent accidents and injuries.

- Utilized various hand tools and power equipment to complete finishing processes, such as grinding, polishing, and deburring, ensuring a high-quality final product.

Frequently Asked Questions (FAQ’s) For Hammer Operator

What are the key skills required to be a successful Hammer Operator?

Essential skills for a Hammer Operator include proficiency in hammer operation, maintenance, and safety. They should also possess a strong understanding of metallurgy and metalworking techniques, as well as the ability to collaborate with engineers and designers to develop and execute fabrication processes.

What is the work environment of a Hammer Operator like?

Hammer Operators typically work in industrial settings, such as manufacturing plants or fabrication shops. The work environment can be noisy and involves exposure to heavy machinery and metalworking processes. Adherence to safety regulations and best practices is crucial to maintain a safe and efficient work environment.

What are the career advancement opportunities for a Hammer Operator?

With experience and additional training, Hammer Operators can advance to roles such as Supervisor, Lead Operator, or Quality Control Inspector. They can also specialize in specific areas of metalworking, such as forging, fabrication, or welding.

How can I prepare for a career as a Hammer Operator?

To prepare for a career as a Hammer Operator, consider pursuing an Associate’s Degree in Industrial Technology or a related field. Additionally, hands-on experience in metalworking or fabrication can be beneficial. Seeking opportunities for apprenticeships or internships can provide valuable training and industry connections.

What are the safety precautions that Hammer Operators must follow?

Hammer Operators must adhere to strict safety regulations and best practices to prevent accidents and injuries. This includes wearing appropriate personal protective equipment, following proper operating procedures, maintaining a clean and organized work area, and being aware of potential hazards.

What is the importance of proper hammer maintenance for a Hammer Operator?

Proper hammer maintenance is crucial for Hammer Operators to ensure optimal performance and prevent breakdowns. Regular inspections, adjustments, and repairs help extend the lifespan of the hammer, minimize downtime, and maintain accuracy and precision in metalworking processes.

How does a Hammer Operator contribute to the overall production process?

Hammer Operators play a vital role in the production process by shaping, forging, and fabricating metal components and structures. Their skills and expertise contribute to the quality, durability, and precision of the final products, ensuring that they meet specifications and industry standards.