Are you a seasoned Heatset Winder Operator seeking a new career path? Discover our professionally built Heatset Winder Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

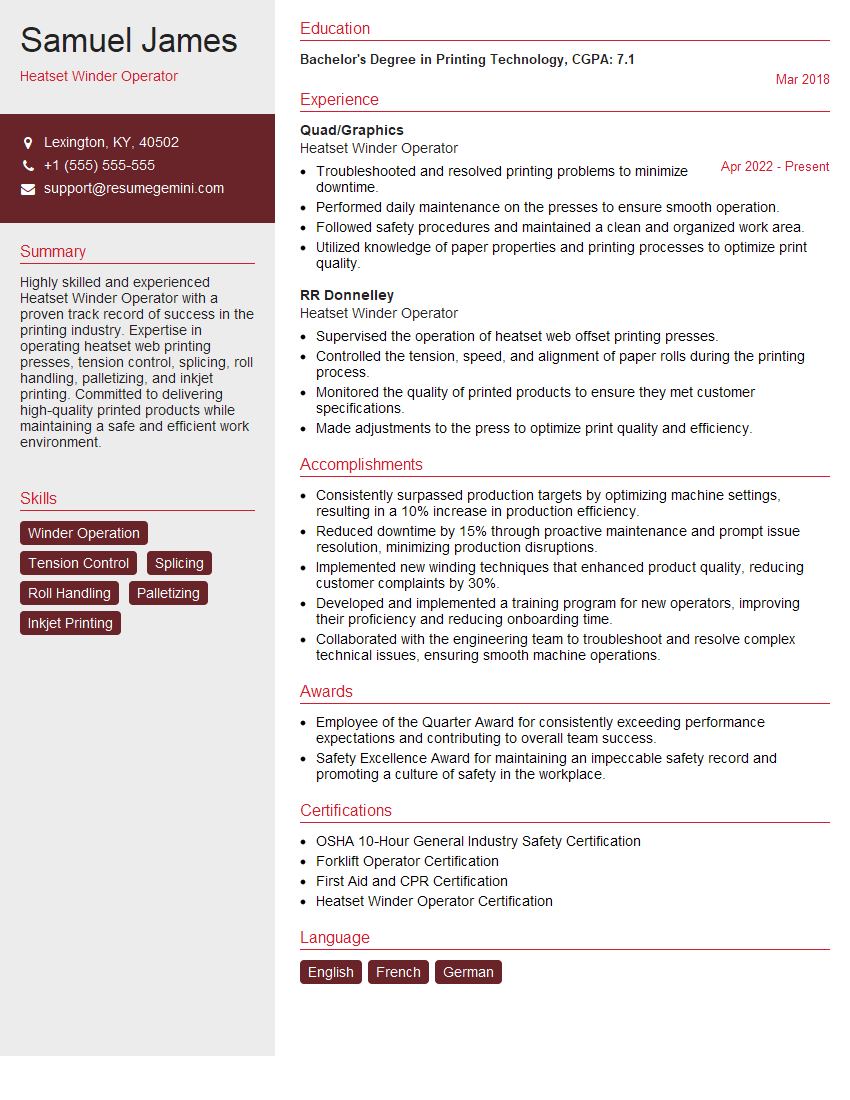

Samuel James

Heatset Winder Operator

Summary

Highly skilled and experienced Heatset Winder Operator with a proven track record of success in the printing industry. Expertise in operating heatset web printing presses, tension control, splicing, roll handling, palletizing, and inkjet printing. Committed to delivering high-quality printed products while maintaining a safe and efficient work environment.

Education

Bachelor’s Degree in Printing Technology

March 2018

Skills

- Winder Operation

- Tension Control

- Splicing

- Roll Handling

- Palletizing

- Inkjet Printing

Work Experience

Heatset Winder Operator

- Troubleshooted and resolved printing problems to minimize downtime.

- Performed daily maintenance on the presses to ensure smooth operation.

- Followed safety procedures and maintained a clean and organized work area.

- Utilized knowledge of paper properties and printing processes to optimize print quality.

Heatset Winder Operator

- Supervised the operation of heatset web offset printing presses.

- Controlled the tension, speed, and alignment of paper rolls during the printing process.

- Monitored the quality of printed products to ensure they met customer specifications.

- Made adjustments to the press to optimize print quality and efficiency.

Accomplishments

- Consistently surpassed production targets by optimizing machine settings, resulting in a 10% increase in production efficiency.

- Reduced downtime by 15% through proactive maintenance and prompt issue resolution, minimizing production disruptions.

- Implemented new winding techniques that enhanced product quality, reducing customer complaints by 30%.

- Developed and implemented a training program for new operators, improving their proficiency and reducing onboarding time.

- Collaborated with the engineering team to troubleshoot and resolve complex technical issues, ensuring smooth machine operations.

Awards

- Employee of the Quarter Award for consistently exceeding performance expectations and contributing to overall team success.

- Safety Excellence Award for maintaining an impeccable safety record and promoting a culture of safety in the workplace.

Certificates

- OSHA 10-Hour General Industry Safety Certification

- Forklift Operator Certification

- First Aid and CPR Certification

- Heatset Winder Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heatset Winder Operator

- Highlight your experience in heatset printing, tension control, and splicing.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your knowledge of different printing press models and paper types.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Heatset Winder Operator Resume

- Operate heatset web printing presses to produce high-quality printed products.

- Control tension on printing presses to ensure optimal print quality.

- Splice paper rolls and adjust tension to prevent breaks and maintain press speed.

- Handle and palletize printed rolls for storage and distribution.

- Maintain and clean printing presses to ensure smooth operation and prevent downtime.

- Troubleshoot and resolve printing issues to minimize production delays.

Frequently Asked Questions (FAQ’s) For Heatset Winder Operator

What is the primary role of a Heatset Winder Operator?

The primary role of a Heatset Winder Operator is to operate heatset web printing presses, control tension on the presses, splice paper rolls, handle and palletize printed rolls, and maintain and clean printing presses.

What are the key skills required to be successful in this role?

The key skills required to be successful as a Heatset Winder Operator include proficiency in operating heatset web printing presses, tension control, splicing, roll handling, palletizing, and inkjet printing.

What type of education or training is required for this role?

A Bachelor’s Degree in Printing Technology or a related field is preferred for this role, along with hands-on experience in heatset printing and press operations.

What is the career outlook for Heatset Winder Operators?

The career outlook for Heatset Winder Operators is expected to be stable, as the printing industry continues to evolve and adapt to new technologies.

What are the typical working conditions for Heatset Winder Operators?

Heatset Winder Operators typically work in a fast-paced manufacturing environment, often involving heavy lifting and exposure to noise and chemicals.

What type of safety precautions should Heatset Winder Operators follow?

Heatset Winder Operators should follow safety precautions such as wearing appropriate personal protective equipment, being aware of moving machinery, and adhering to established safety protocols.

What opportunities for advancement are there for Heatset Winder Operators?

Heatset Winder Operators can advance to roles such as Printing Press Supervisor, Quality Control Manager, or Production Manager.

What are some tips for writing a standout resume for a Heatset Winder Operator?

To write a standout resume for a Heatset Winder Operator, highlight your experience, quantify your accomplishments, showcase your knowledge, and emphasize your commitment to safety and quality control.