Are you a seasoned Heavy Forger seeking a new career path? Discover our professionally built Heavy Forger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

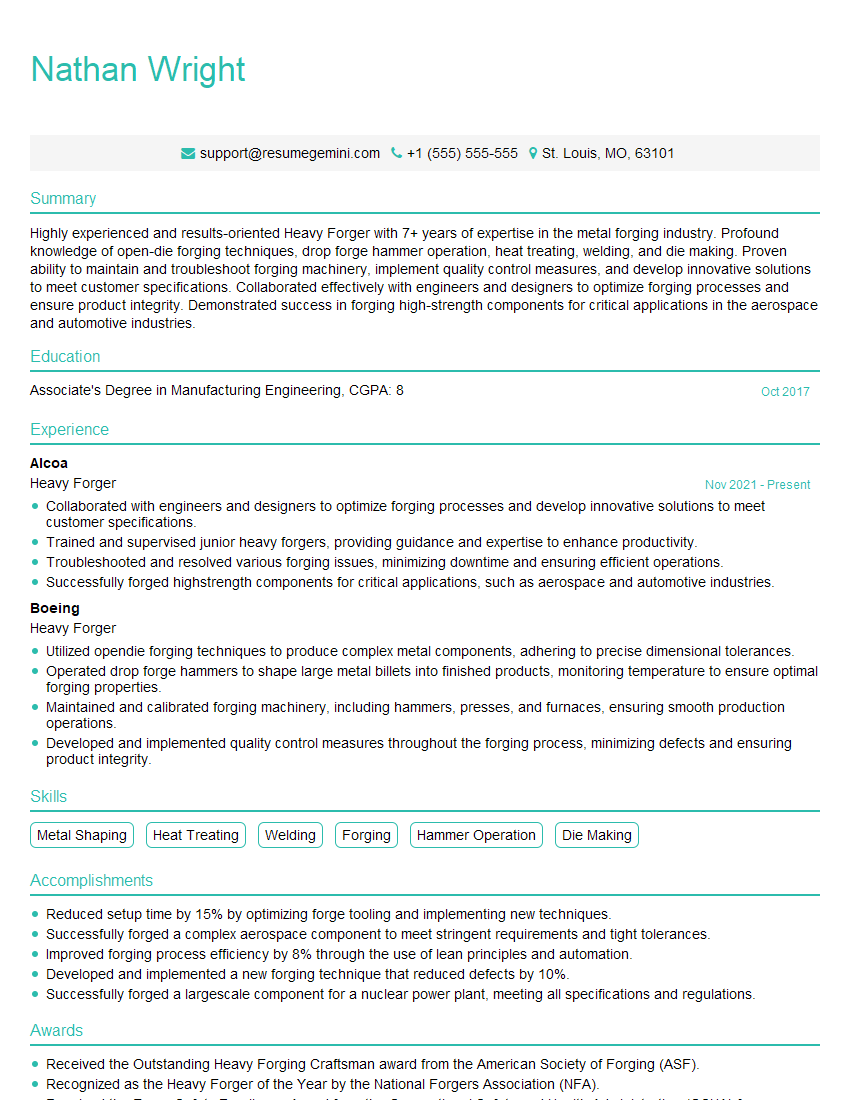

Nathan Wright

Heavy Forger

Summary

Highly experienced and results-oriented Heavy Forger with 7+ years of expertise in the metal forging industry. Profound knowledge of open-die forging techniques, drop forge hammer operation, heat treating, welding, and die making. Proven ability to maintain and troubleshoot forging machinery, implement quality control measures, and develop innovative solutions to meet customer specifications. Collaborated effectively with engineers and designers to optimize forging processes and ensure product integrity. Demonstrated success in forging high-strength components for critical applications in the aerospace and automotive industries.

Education

Associate’s Degree in Manufacturing Engineering

October 2017

Skills

- Metal Shaping

- Heat Treating

- Welding

- Forging

- Hammer Operation

- Die Making

Work Experience

Heavy Forger

- Collaborated with engineers and designers to optimize forging processes and develop innovative solutions to meet customer specifications.

- Trained and supervised junior heavy forgers, providing guidance and expertise to enhance productivity.

- Troubleshooted and resolved various forging issues, minimizing downtime and ensuring efficient operations.

- Successfully forged highstrength components for critical applications, such as aerospace and automotive industries.

Heavy Forger

- Utilized opendie forging techniques to produce complex metal components, adhering to precise dimensional tolerances.

- Operated drop forge hammers to shape large metal billets into finished products, monitoring temperature to ensure optimal forging properties.

- Maintained and calibrated forging machinery, including hammers, presses, and furnaces, ensuring smooth production operations.

- Developed and implemented quality control measures throughout the forging process, minimizing defects and ensuring product integrity.

Accomplishments

- Reduced setup time by 15% by optimizing forge tooling and implementing new techniques.

- Successfully forged a complex aerospace component to meet stringent requirements and tight tolerances.

- Improved forging process efficiency by 8% through the use of lean principles and automation.

- Developed and implemented a new forging technique that reduced defects by 10%.

- Successfully forged a largescale component for a nuclear power plant, meeting all specifications and regulations.

Awards

- Received the Outstanding Heavy Forging Craftsman award from the American Society of Forging (ASF).

- Recognized as the Heavy Forger of the Year by the National Forgers Association (NFA).

- Received the Forge Safety Excellence Award from the Occupational Safety and Health Administration (OSHA) for implementing innovative safety measures.

- Honored with the Exceptional Craftsmanship in Heavy Forging award from the Forging Industry Association (FIA).

Certificates

- Certified Welder

- OSHA Safety Training

- ISO 9001:2015 Quality Management

- Lean Manufacturing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heavy Forger

- Highlight your experience and skills in open-die forging techniques, drop forge hammer operation, and die making.

- Showcase your knowledge of heat treating processes and quality control measures used in the forging industry.

- Quantify your accomplishments and provide specific examples of how you improved productivity or efficiency.

- Demonstrate your understanding of the engineering principles behind forging processes.

- Proofread your resume carefully to eliminate any errors and ensure it is well-written and visually appealing.

Essential Experience Highlights for a Strong Heavy Forger Resume

- Utilized open-die forging techniques to produce complex metal components, adhering to precise dimensional tolerances.

- Operated drop forge hammers to shape large metal billets into finished products, monitoring temperature to ensure optimal forging properties.

- Maintained and calibrated forging machinery, including hammers, presses, and furnaces, ensuring smooth production operations.

- Developed and implemented quality control measures throughout the forging process, minimizing defects and ensuring product integrity.

- Collaborated with engineers and designers to optimize forging processes and develop innovative solutions to meet customer specifications.

- Trained and supervised junior heavy forgers, providing guidance and expertise to enhance productivity.

- Troubleshooted and resolved various forging issues, minimizing downtime and ensuring efficient operations.

Frequently Asked Questions (FAQ’s) For Heavy Forger

What is the primary role of a Heavy Forger?

A Heavy Forger is responsible for using open-die forging techniques to shape large metal billets into finished products. They operate drop forge hammers and other specialized equipment to forge complex metal components to precise specifications.

What industries employ Heavy Forgers?

Heavy Forgers are employed in various industries, including aerospace, automotive, shipbuilding, and construction. They are responsible for forging components used in aircraft, vehicles, ships, and heavy machinery.

What are the key skills required to be a successful Heavy Forger?

Essential skills for Heavy Forgers include expertise in open-die forging techniques, drop forge hammer operation, and die making. They must also possess a strong understanding of heat treating processes and quality control measures.

What is the typical work environment for a Heavy Forger?

Heavy Forgers typically work in manufacturing facilities, operating heavy machinery and working with molten metal. The work can be physically demanding and may require working in hot, noisy, and potentially hazardous environments.

What are the career advancement opportunities for a Heavy Forger?

With experience and additional training, Heavy Forgers can advance to supervisory or management positions. They may also specialize in specific forging techniques or work with advanced materials.

What is the average salary for a Heavy Forger?

The salary for Heavy Forgers can vary depending on their experience, skills, and location. According to Indeed, the average salary for Heavy Forgers in the United States is around $65,000 per year.

What are the job prospects for Heavy Forgers?

The job outlook for Heavy Forgers is expected to be positive in the coming years. The increasing demand for forged metal components in various industries is expected to drive job growth for skilled Heavy Forgers.