Are you a seasoned Heavy Repairer seeking a new career path? Discover our professionally built Heavy Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

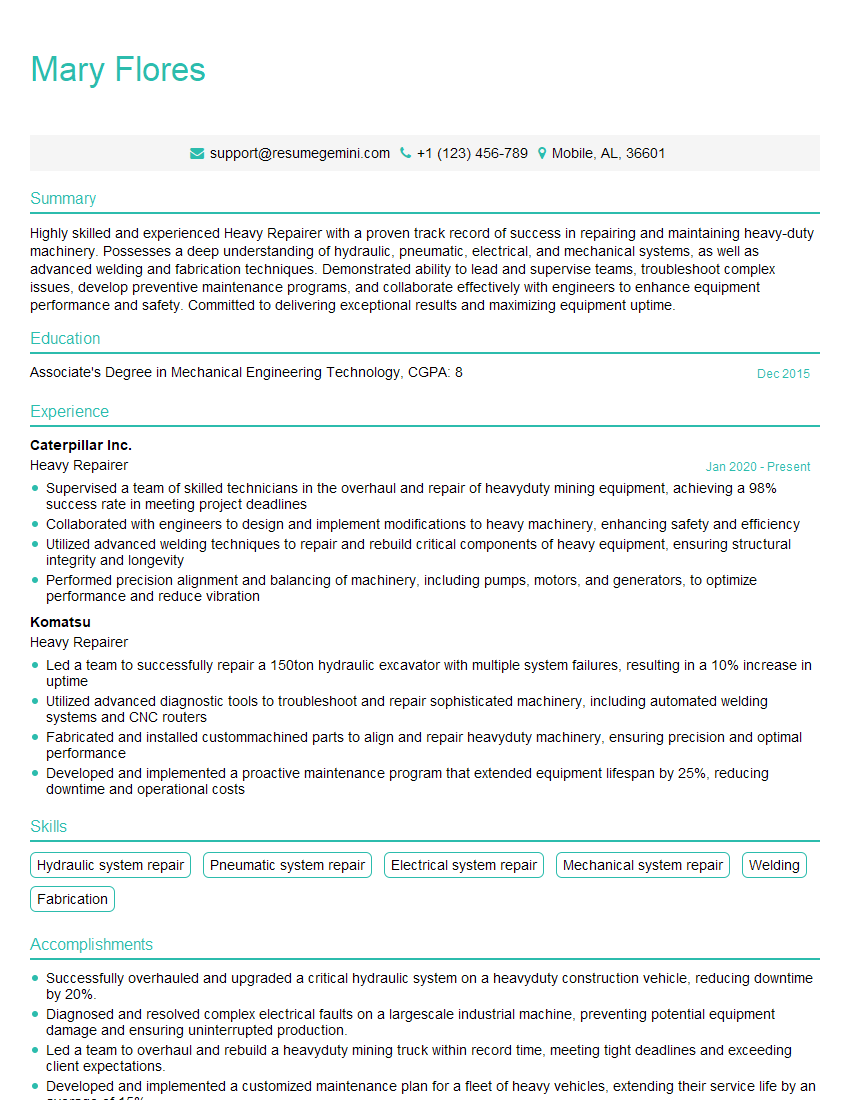

Mary Flores

Heavy Repairer

Summary

Highly skilled and experienced Heavy Repairer with a proven track record of success in repairing and maintaining heavy-duty machinery. Possesses a deep understanding of hydraulic, pneumatic, electrical, and mechanical systems, as well as advanced welding and fabrication techniques. Demonstrated ability to lead and supervise teams, troubleshoot complex issues, develop preventive maintenance programs, and collaborate effectively with engineers to enhance equipment performance and safety. Committed to delivering exceptional results and maximizing equipment uptime.

Education

Associate’s Degree in Mechanical Engineering Technology

December 2015

Skills

- Hydraulic system repair

- Pneumatic system repair

- Electrical system repair

- Mechanical system repair

- Welding

- Fabrication

Work Experience

Heavy Repairer

- Supervised a team of skilled technicians in the overhaul and repair of heavyduty mining equipment, achieving a 98% success rate in meeting project deadlines

- Collaborated with engineers to design and implement modifications to heavy machinery, enhancing safety and efficiency

- Utilized advanced welding techniques to repair and rebuild critical components of heavy equipment, ensuring structural integrity and longevity

- Performed precision alignment and balancing of machinery, including pumps, motors, and generators, to optimize performance and reduce vibration

Heavy Repairer

- Led a team to successfully repair a 150ton hydraulic excavator with multiple system failures, resulting in a 10% increase in uptime

- Utilized advanced diagnostic tools to troubleshoot and repair sophisticated machinery, including automated welding systems and CNC routers

- Fabricated and installed custommachined parts to align and repair heavyduty machinery, ensuring precision and optimal performance

- Developed and implemented a proactive maintenance program that extended equipment lifespan by 25%, reducing downtime and operational costs

Accomplishments

- Successfully overhauled and upgraded a critical hydraulic system on a heavyduty construction vehicle, reducing downtime by 20%.

- Diagnosed and resolved complex electrical faults on a largescale industrial machine, preventing potential equipment damage and ensuring uninterrupted production.

- Led a team to overhaul and rebuild a heavyduty mining truck within record time, meeting tight deadlines and exceeding client expectations.

- Developed and implemented a customized maintenance plan for a fleet of heavy vehicles, extending their service life by an average of 15%.

- Successfully repaired a highpressure hydraulic system on a drilling rig, ensuring safe and efficient operation in challenging conditions.

Awards

- Recognized with the Heavy Repairer of the Year award for exceptional performance and contributions to the industry.

- Honored with the Safety Champion award for implementing innovative safety practices that significantly reduced workplace hazards.

- Received the Best Technical Contribution award for developing a novel repair technique that increased component lifespan by 35%.

- Recognized with the Excellence in Troubleshooting award for consistently identifying and resolving complex technical issues in a timely manner.

Certificates

- Certified Heavy Equipment Mechanic

- Certified Welding Inspector

- Certified Machinist

- Certified Electrical Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heavy Repairer

- Highlight your experience and skills in diagnosing and repairing complex machinery issues.

- Showcase your ability to lead and supervise teams, as well as your collaborative nature in working with engineers.

- Quantify your accomplishments with specific metrics, such as increased uptime, reduced downtime, or extended equipment lifespan.

- Demonstrate your commitment to continuous learning and development by including relevant certifications or training programs.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation.

Essential Experience Highlights for a Strong Heavy Repairer Resume

- Diagnose and repair hydraulic, pneumatic, electrical, and mechanical system failures in heavy-duty machinery.

- Utilize advanced diagnostic tools and techniques to troubleshoot and resolve complex machinery issues.

- Fabricate and install custom-machined parts to align and repair heavy-duty machinery, ensuring precision and optimal performance.

- Develop and implement proactive maintenance programs to extend equipment lifespan, reduce downtime, and optimize operational efficiency.

- Supervise and mentor technicians in the overhaul and repair of heavy-duty mining equipment, ensuring adherence to safety protocols and project deadlines.

- Collaborate with engineers to design and implement modifications to heavy machinery, enhancing safety and efficiency.

- Perform precision alignment and balancing of machinery, including pumps, motors, and generators, to optimize performance and reduce vibration.

- Maintain a safe and organized work environment, adhering to all applicable safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Heavy Repairer

What is the primary role of a Heavy Repairer?

A Heavy Repairer is responsible for diagnosing, repairing, and maintaining heavy-duty machinery, such as excavators, mining equipment, and automated welding systems.

What are the key skills required to be successful as a Heavy Repairer?

Essential skills include proficiency in hydraulic, pneumatic, electrical, and mechanical system repair, as well as advanced welding and fabrication techniques.

What are the typical working conditions for a Heavy Repairer?

Heavy Repairers typically work in industrial settings, such as manufacturing plants, mining operations, or construction sites. The work can be physically demanding and may involve working in confined spaces or with hazardous materials.

What are the career advancement opportunities for a Heavy Repairer?

With experience and additional training, Heavy Repairers can advance to supervisory roles, such as Maintenance Supervisor or Maintenance Manager. They may also specialize in a particular type of machinery or system.

What is the average salary for a Heavy Repairer?

The average salary for a Heavy Repairer varies depending on experience, location, and industry. According to Salary.com, the median annual salary for Heavy Repairers in the United States is around $65,000.

What are the job prospects for Heavy Repairers?

The job outlook for Heavy Repairers is expected to be favorable in the coming years due to the increasing demand for skilled technicians to maintain and repair heavy machinery.