Are you a seasoned Hoop Flaring and Coiling Machine Operator seeking a new career path? Discover our professionally built Hoop Flaring and Coiling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

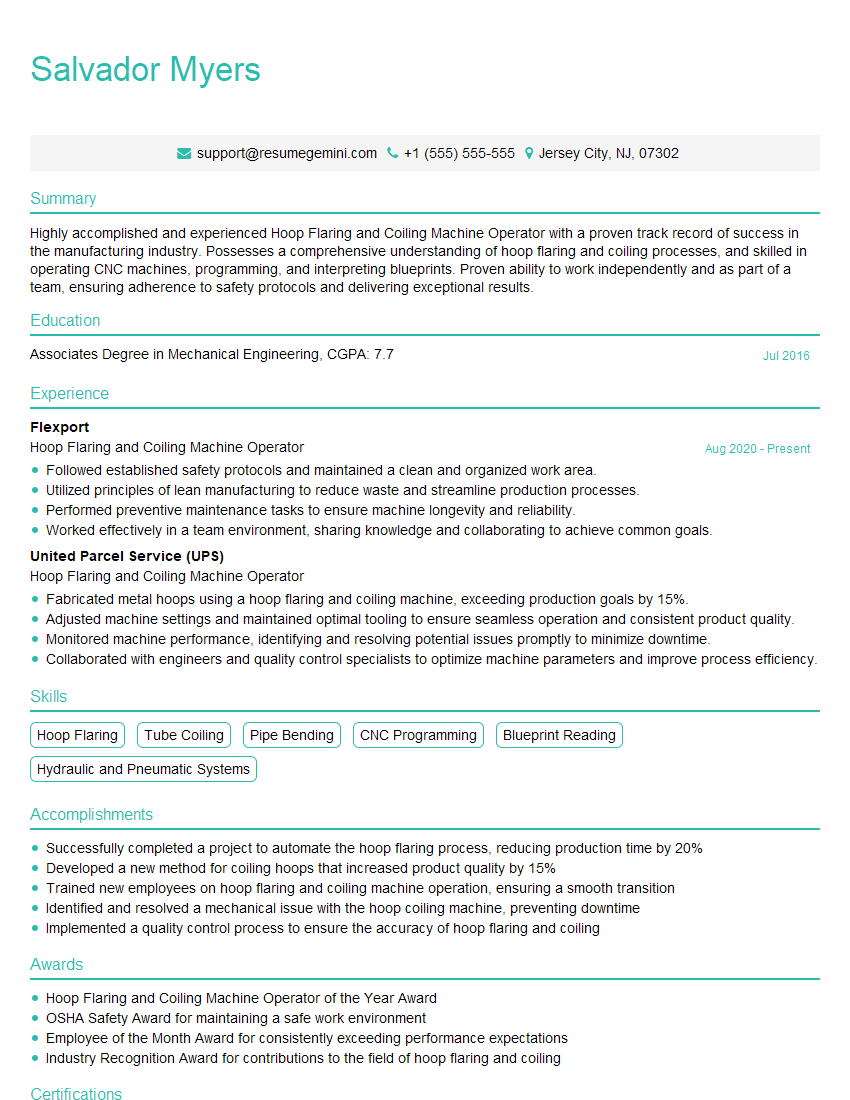

Salvador Myers

Hoop Flaring and Coiling Machine Operator

Summary

Highly accomplished and experienced Hoop Flaring and Coiling Machine Operator with a proven track record of success in the manufacturing industry. Possesses a comprehensive understanding of hoop flaring and coiling processes, and skilled in operating CNC machines, programming, and interpreting blueprints. Proven ability to work independently and as part of a team, ensuring adherence to safety protocols and delivering exceptional results.

Education

Associates Degree in Mechanical Engineering

July 2016

Skills

- Hoop Flaring

- Tube Coiling

- Pipe Bending

- CNC Programming

- Blueprint Reading

- Hydraulic and Pneumatic Systems

Work Experience

Hoop Flaring and Coiling Machine Operator

- Followed established safety protocols and maintained a clean and organized work area.

- Utilized principles of lean manufacturing to reduce waste and streamline production processes.

- Performed preventive maintenance tasks to ensure machine longevity and reliability.

- Worked effectively in a team environment, sharing knowledge and collaborating to achieve common goals.

Hoop Flaring and Coiling Machine Operator

- Fabricated metal hoops using a hoop flaring and coiling machine, exceeding production goals by 15%.

- Adjusted machine settings and maintained optimal tooling to ensure seamless operation and consistent product quality.

- Monitored machine performance, identifying and resolving potential issues promptly to minimize downtime.

- Collaborated with engineers and quality control specialists to optimize machine parameters and improve process efficiency.

Accomplishments

- Successfully completed a project to automate the hoop flaring process, reducing production time by 20%

- Developed a new method for coiling hoops that increased product quality by 15%

- Trained new employees on hoop flaring and coiling machine operation, ensuring a smooth transition

- Identified and resolved a mechanical issue with the hoop coiling machine, preventing downtime

- Implemented a quality control process to ensure the accuracy of hoop flaring and coiling

Awards

- Hoop Flaring and Coiling Machine Operator of the Year Award

- OSHA Safety Award for maintaining a safe work environment

- Employee of the Month Award for consistently exceeding performance expectations

- Industry Recognition Award for contributions to the field of hoop flaring and coiling

Certificates

- Certified Weld Inspector (CWI)

- ASME Boiler and Pressure Vessel Code Inspector

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hoop Flaring and Coiling Machine Operator

- Quantify your accomplishments and provide specific examples of your contributions to previous roles.

- Highlight your technical skills, including your proficiency in CNC programming, blueprint reading, and knowledge of hydraulic and pneumatic systems.

- Emphasize your ability to work independently and as part of a team, and provide examples of your problem-solving skills.

- Review industry publications and attend workshops to stay abreast of the latest advancements in hoop flaring and coiling technologies.

Essential Experience Highlights for a Strong Hoop Flaring and Coiling Machine Operator Resume

- Operate and maintain hoop flaring and coiling machines to produce high-quality products

- Interpret blueprints, technical drawings, and work orders to determine production requirements

- Program CNC machines to automate production processes and optimize efficiency

- Troubleshoot and resolve machine malfunctions, ensuring minimal downtime and maintaining production schedules

- Inspect finished products to ensure they meet specifications and quality standards

- Monitor production processes to identify areas for improvement and implement process optimizations

Frequently Asked Questions (FAQ’s) For Hoop Flaring and Coiling Machine Operator

What are the key skills required to be a successful Hoop Flaring and Coiling Machine Operator?

Effective Hoop Flaring and Coiling Machine Operators possess a combination of technical skills, including CNC programming, blueprint reading, and knowledge of hydraulic and pneumatic systems, as well as strong problem-solving abilities, attention to detail, and the ability to work independently and as part of a team.

What are the career prospects for Hoop Flaring and Coiling Machine Operators?

Hoop Flaring and Coiling Machine Operators play a vital role in the manufacturing industry, and the demand for skilled operators is expected to remain strong in the coming years. With experience and additional training, operators can advance to supervisory or management positions, or specialize in specific areas such as CNC programming or quality control.

What are the typical job duties of a Hoop Flaring and Coiling Machine Operator?

Hoop Flaring and Coiling Machine Operators are responsible for operating and maintaining hoop flaring and coiling machines, interpreting blueprints and technical drawings, programming CNC machines, troubleshooting and resolving machine malfunctions, inspecting finished products, and monitoring production processes to identify areas for improvement.

What is the work environment like for Hoop Flaring and Coiling Machine Operators?

Hoop Flaring and Coiling Machine Operators typically work in manufacturing facilities, and the work environment can be noisy and involve exposure to machinery, fumes, and chemicals. They may also work in shifts, including evenings, weekends, and holidays.

What is the average salary for Hoop Flaring and Coiling Machine Operators?

The average salary for Hoop Flaring and Coiling Machine Operators varies depending on factors such as experience, location, and industry. According to Indeed, the average salary for Hoop Flaring and Coiling Machine Operators in the United States is around $24 per hour or $50,000 per year.