Are you a seasoned Horizontal Boring Mill Set Up Operator seeking a new career path? Discover our professionally built Horizontal Boring Mill Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

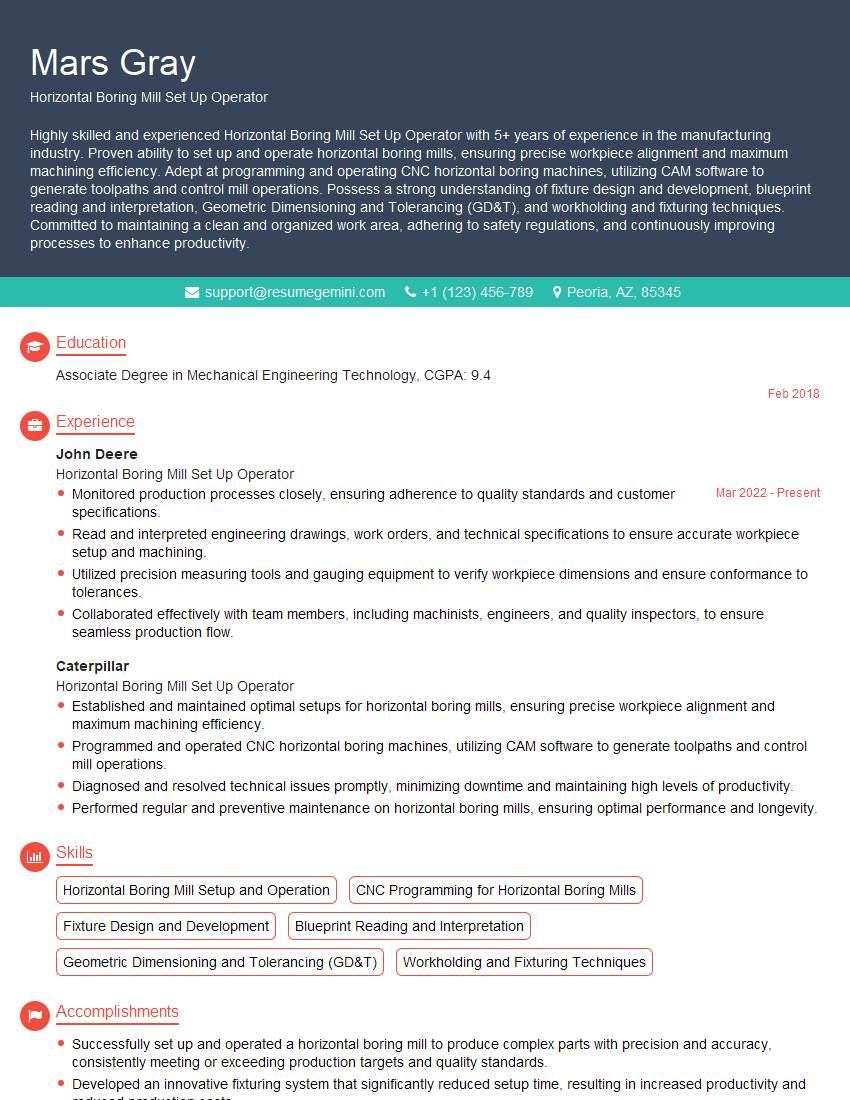

Mars Gray

Horizontal Boring Mill Set Up Operator

Summary

Highly skilled and experienced Horizontal Boring Mill Set Up Operator with 5+ years of experience in the manufacturing industry. Proven ability to set up and operate horizontal boring mills, ensuring precise workpiece alignment and maximum machining efficiency. Adept at programming and operating CNC horizontal boring machines, utilizing CAM software to generate toolpaths and control mill operations. Possess a strong understanding of fixture design and development, blueprint reading and interpretation, Geometric Dimensioning and Tolerancing (GD&T), and workholding and fixturing techniques. Committed to maintaining a clean and organized work area, adhering to safety regulations, and continuously improving processes to enhance productivity.

Education

Associate Degree in Mechanical Engineering Technology

February 2018

Skills

- Horizontal Boring Mill Setup and Operation

- CNC Programming for Horizontal Boring Mills

- Fixture Design and Development

- Blueprint Reading and Interpretation

- Geometric Dimensioning and Tolerancing (GD&T)

- Workholding and Fixturing Techniques

Work Experience

Horizontal Boring Mill Set Up Operator

- Monitored production processes closely, ensuring adherence to quality standards and customer specifications.

- Read and interpreted engineering drawings, work orders, and technical specifications to ensure accurate workpiece setup and machining.

- Utilized precision measuring tools and gauging equipment to verify workpiece dimensions and ensure conformance to tolerances.

- Collaborated effectively with team members, including machinists, engineers, and quality inspectors, to ensure seamless production flow.

Horizontal Boring Mill Set Up Operator

- Established and maintained optimal setups for horizontal boring mills, ensuring precise workpiece alignment and maximum machining efficiency.

- Programmed and operated CNC horizontal boring machines, utilizing CAM software to generate toolpaths and control mill operations.

- Diagnosed and resolved technical issues promptly, minimizing downtime and maintaining high levels of productivity.

- Performed regular and preventive maintenance on horizontal boring mills, ensuring optimal performance and longevity.

Accomplishments

- Successfully set up and operated a horizontal boring mill to produce complex parts with precision and accuracy, consistently meeting or exceeding production targets and quality standards.

- Developed an innovative fixturing system that significantly reduced setup time, resulting in increased productivity and reduced production costs.

- Identified and corrected a critical alignment issue on a horizontal boring mill, preventing potential equipment damage and ensuring optimal performance.

- Successfully programmed and operated a horizontal boring mill to produce intricate components for aerospace applications, ensuring high precision and dimensional tolerances.

- Trained and mentored new horizontal boring mill operators, effectively transferring knowledge and skills to maintain high production standards.

Certificates

- Certified Horizontal Boring Mill Operator

- ISO 9001:2015 Quality Management System Auditor

- Certified Safety Inspector

- Lean Six Sigma Green Belt

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Horizontal Boring Mill Set Up Operator

- Highlight your skills and experience in horizontal boring mill setup and operation, as well as your ability to program and operate CNC machines.

- Provide specific examples of your work, such as projects where you successfully set up and operated a horizontal boring mill to produce high-quality parts.

- Use action verbs and quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Horizontal Boring Mill Set Up Operator Resume

- Set up and maintain optimal setups for horizontal boring mills, ensuring precise workpiece alignment and maximum machining efficiency.

- Program and operate CNC horizontal boring machines, utilizing CAM software to generate toolpaths and control mill operations.

- Diagnose and resolve technical issues promptly, minimizing downtime and maintaining high levels of productivity.

- Perform regular and preventive maintenance on horizontal boring mills, ensuring optimal performance and longevity.

- Monitor production processes closely, ensuring adherence to quality standards and customer specifications.

- Read and interpret engineering drawings, work orders, and technical specifications to ensure accurate workpiece setup and machining.

- Utilized precision measuring tools and gauging equipment to verify workpiece dimensions and ensure conformance to tolerances.

Frequently Asked Questions (FAQ’s) For Horizontal Boring Mill Set Up Operator

What are the primary responsibilities of a Horizontal Boring Mill Set Up Operator?

The primary responsibilities of a Horizontal Boring Mill Set Up Operator include setting up and maintaining optimal setups for horizontal boring mills, programming and operating CNC horizontal boring machines, diagnosing and resolving technical issues, performing regular and preventive maintenance, monitoring production processes, and ensuring adherence to quality standards.

What skills are required to be a successful Horizontal Boring Mill Set Up Operator?

To be a successful Horizontal Boring Mill Set Up Operator, you will need skills in horizontal boring mill setup and operation, CNC programming for horizontal boring mills, fixture design and development, blueprint reading and interpretation, Geometric Dimensioning and Tolerancing (GD&T), and workholding and fixturing techniques.

What is the typical work environment for a Horizontal Boring Mill Set Up Operator?

Horizontal Boring Mill Set Up Operators typically work in a manufacturing environment, often in a machine shop or factory setting. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the career prospects for a Horizontal Boring Mill Set Up Operator?

With experience and additional training, Horizontal Boring Mill Set Up Operators can advance to supervisory or management positions, or specialize in a particular area of machining, such as programming or maintenance.

What is the salary range for a Horizontal Boring Mill Set Up Operator?

The salary range for a Horizontal Boring Mill Set Up Operator varies depending on experience, location, and company size. According to Indeed, the average salary for a Horizontal Boring Mill Set Up Operator in the United States is $24.50 per hour.

What are the educational requirements for a Horizontal Boring Mill Set Up Operator?

While there are no formal educational requirements for a Horizontal Boring Mill Set Up Operator, many employers prefer candidates with an associate degree in a related field, such as mechanical engineering technology or manufacturing.