Are you a seasoned Hot Dipper seeking a new career path? Discover our professionally built Hot Dipper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

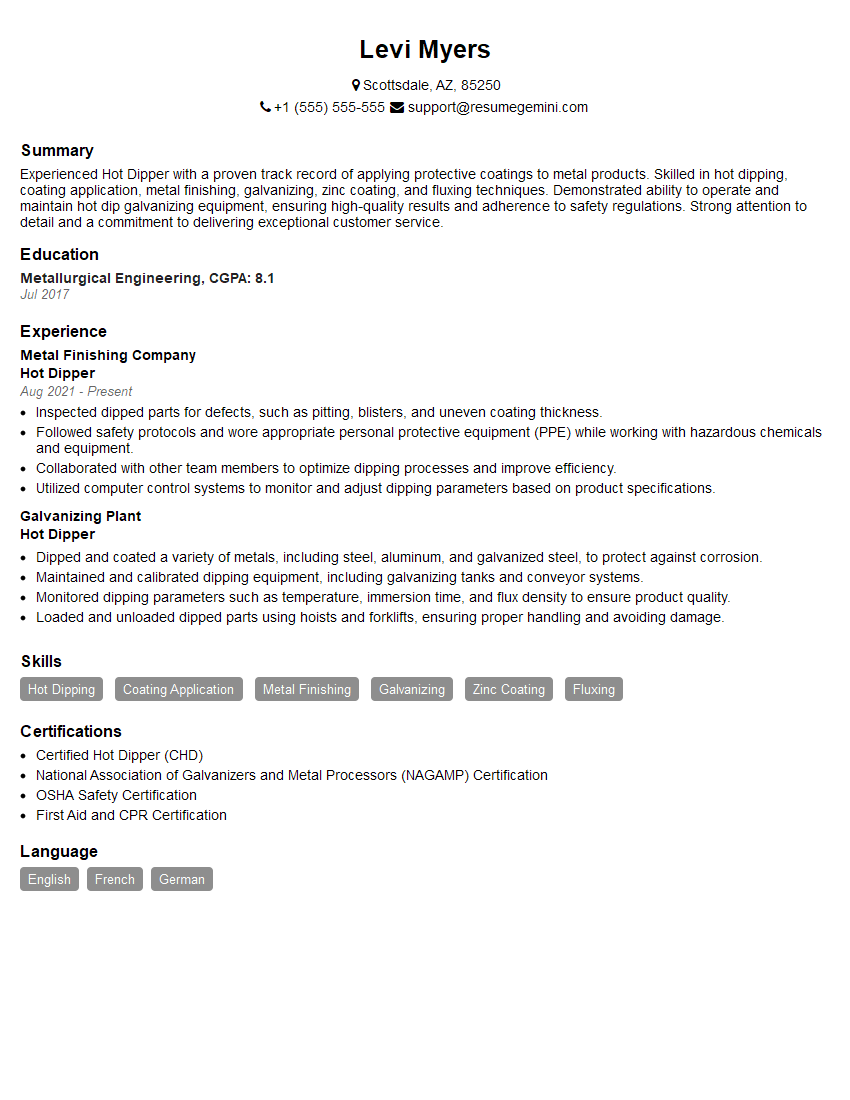

Levi Myers

Hot Dipper

Summary

Experienced Hot Dipper with a proven track record of applying protective coatings to metal products. Skilled in hot dipping, coating application, metal finishing, galvanizing, zinc coating, and fluxing techniques. Demonstrated ability to operate and maintain hot dip galvanizing equipment, ensuring high-quality results and adherence to safety regulations. Strong attention to detail and a commitment to delivering exceptional customer service.

Education

Metallurgical Engineering

July 2017

Skills

- Hot Dipping

- Coating Application

- Metal Finishing

- Galvanizing

- Zinc Coating

- Fluxing

Work Experience

Hot Dipper

- Inspected dipped parts for defects, such as pitting, blisters, and uneven coating thickness.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) while working with hazardous chemicals and equipment.

- Collaborated with other team members to optimize dipping processes and improve efficiency.

- Utilized computer control systems to monitor and adjust dipping parameters based on product specifications.

Hot Dipper

- Dipped and coated a variety of metals, including steel, aluminum, and galvanized steel, to protect against corrosion.

- Maintained and calibrated dipping equipment, including galvanizing tanks and conveyor systems.

- Monitored dipping parameters such as temperature, immersion time, and flux density to ensure product quality.

- Loaded and unloaded dipped parts using hoists and forklifts, ensuring proper handling and avoiding damage.

Certificates

- Certified Hot Dipper (CHD)

- National Association of Galvanizers and Metal Processors (NAGAMP) Certification

- OSHA Safety Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Dipper

- Highlight your technical skills and experience in hot dipping and metal finishing techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of safety regulations and commitment to maintaining a safe work environment.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Hot Dipper Resume

- Operate and maintain hot dip galvanizing equipment, including dipping tanks, conveyor systems, and drying ovens

- Prepare metal surfaces for coating by cleaning, degreasing, and fluxing

- Immerse metal products into molten zinc to create a protective coating

- Control dipping time and temperature to ensure uniform coating thickness and adhesion

- Monitor finished products for coating quality and adherence to specifications

- Maintain a clean and safe work environment, adhering to all safety regulations

- Troubleshoot and resolve equipment issues to ensure smooth operations

Frequently Asked Questions (FAQ’s) For Hot Dipper

What is hot dipping?

Hot dipping is a metal finishing process that involves immersing metal products into molten zinc to create a protective coating. This coating protects the metal from corrosion, wear, and other environmental factors.

What are the different types of hot dip coatings?

There are various types of hot dip coatings, including zinc coating, galvanizing, aluminum coating, and tinning. Each type of coating offers different properties and is suitable for specific applications.

What are the benefits of hot dip coating?

Hot dip coatings provide several benefits, including corrosion protection, improved durability, enhanced appearance, and increased electrical conductivity.

What industries use hot dip coating?

Hot dip coating is used in various industries, including automotive, construction, manufacturing, and energy. It is commonly used to protect metal components, structures, and equipment from harsh environments.

What are the safety precautions to consider when working with hot dip coating?

Working with hot dip coating requires ????????? ???? ????????????????, such as wearing appropriate protective gear, handling molten metals with caution, and ensuring proper ventilation to avoid exposure to harmful fumes.

What are the career opportunities for Hot Dippers?

Hot Dippers can find employment in metal finishing companies, galvanizing plants, and other industries that utilize hot dip coating processes. They can also pursue advanced training or education to qualify for supervisory or management roles.