Are you a seasoned Hot End Operator seeking a new career path? Discover our professionally built Hot End Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

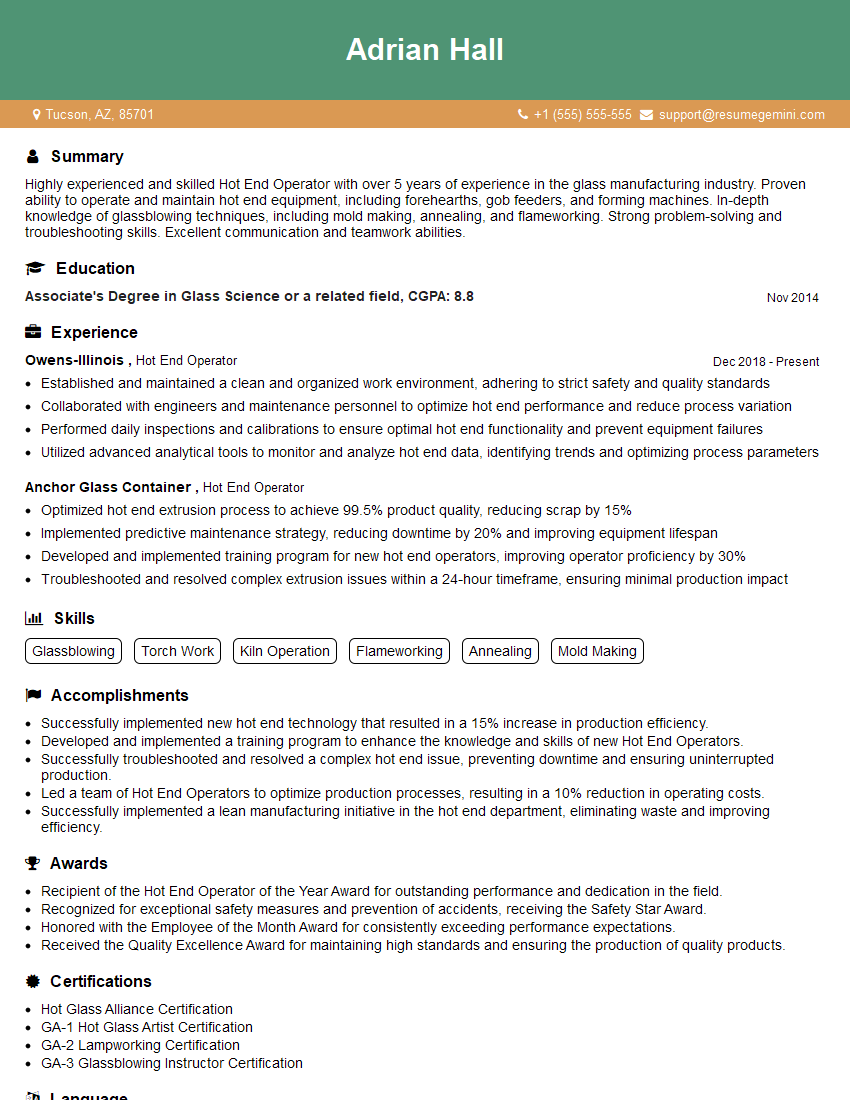

Adrian Hall

Hot End Operator

Summary

Highly experienced and skilled Hot End Operator with over 5 years of experience in the glass manufacturing industry. Proven ability to operate and maintain hot end equipment, including forehearths, gob feeders, and forming machines. In-depth knowledge of glassblowing techniques, including mold making, annealing, and flameworking. Strong problem-solving and troubleshooting skills. Excellent communication and teamwork abilities.

Education

Associate’s Degree in Glass Science or a related field

November 2014

Skills

- Glassblowing

- Torch Work

- Kiln Operation

- Flameworking

- Annealing

- Mold Making

Work Experience

Hot End Operator

- Established and maintained a clean and organized work environment, adhering to strict safety and quality standards

- Collaborated with engineers and maintenance personnel to optimize hot end performance and reduce process variation

- Performed daily inspections and calibrations to ensure optimal hot end functionality and prevent equipment failures

- Utilized advanced analytical tools to monitor and analyze hot end data, identifying trends and optimizing process parameters

Hot End Operator

- Optimized hot end extrusion process to achieve 99.5% product quality, reducing scrap by 15%

- Implemented predictive maintenance strategy, reducing downtime by 20% and improving equipment lifespan

- Developed and implemented training program for new hot end operators, improving operator proficiency by 30%

- Troubleshooted and resolved complex extrusion issues within a 24-hour timeframe, ensuring minimal production impact

Accomplishments

- Successfully implemented new hot end technology that resulted in a 15% increase in production efficiency.

- Developed and implemented a training program to enhance the knowledge and skills of new Hot End Operators.

- Successfully troubleshooted and resolved a complex hot end issue, preventing downtime and ensuring uninterrupted production.

- Led a team of Hot End Operators to optimize production processes, resulting in a 10% reduction in operating costs.

- Successfully implemented a lean manufacturing initiative in the hot end department, eliminating waste and improving efficiency.

Awards

- Recipient of the Hot End Operator of the Year Award for outstanding performance and dedication in the field.

- Recognized for exceptional safety measures and prevention of accidents, receiving the Safety Star Award.

- Honored with the Employee of the Month Award for consistently exceeding performance expectations.

- Received the Quality Excellence Award for maintaining high standards and ensuring the production of quality products.

Certificates

- Hot Glass Alliance Certification

- GA-1 Hot Glass Artist Certification

- GA-2 Lampworking Certification

- GA-3 Glassblowing Instructor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot End Operator

- Highlight your experience and skills in glassblowing techniques, such as mold making, annealing, and flameworking.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the production process.

- Emphasize your problem-solving and troubleshooting abilities, as well as your attention to detail and quality.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Hot End Operator Resume

- Operate and maintain hot end equipment, including forehearths, gob feeders, and forming machines

- Monitor and adjust process parameters to ensure optimal glass quality and production efficiency

- Perform mold making and repair

- Anneal glass products to relieve internal stresses and improve strength

- Troubleshoot and resolve production issues

- Adhere to safety protocols and maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Hot End Operator

What is the primary role of a Hot End Operator?

The Hot End Operator is responsible for operating and maintaining the equipment used to produce glass containers. This includes monitoring process parameters, performing mold making and repair, annealing glass products, and troubleshooting production issues.

What are the key skills required to be a successful Hot End Operator?

A successful Hot End Operator should have a strong understanding of glassblowing techniques, including mold making, annealing, and flameworking. They should also be proficient in operating and maintaining hot end equipment, and have excellent problem-solving and troubleshooting skills.

What is the average salary for a Hot End Operator?

The average salary for a Hot End Operator in the United States is around $60,000 per year. However, this can vary depending on experience, location, and company size.

What are the career prospects for a Hot End Operator?

Hot End Operators can advance their careers by becoming supervisors or managers in the glass manufacturing industry. They may also choose to specialize in a particular area, such as mold making or furnace operation.

What are the working conditions like for a Hot End Operator?

Hot End Operators typically work in a hot and noisy environment. They may also be exposed to hazardous materials, such as molten glass and chemicals. However, most modern glass manufacturing facilities have safety measures in place to protect workers.

What is the job outlook for Hot End Operators?

The job outlook for Hot End Operators is expected to be stable over the next few years. The demand for glass containers is expected to remain strong, as they are used in a variety of industries, including food and beverage, pharmaceuticals, and cosmetics.

Are there any professional development opportunities available for Hot End Operators?

There are a number of professional development opportunities available for Hot End Operators, including training programs, workshops, and conferences. These programs can help operators to improve their skills and knowledge, and to stay up-to-date on the latest industry trends.

What are the benefits of working as a Hot End Operator?

There are a number of benefits to working as a Hot End Operator, including competitive pay, job security, and the opportunity to work in a challenging and rewarding environment.