Are you a seasoned Hot Metal Mixer Operator Helper seeking a new career path? Discover our professionally built Hot Metal Mixer Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

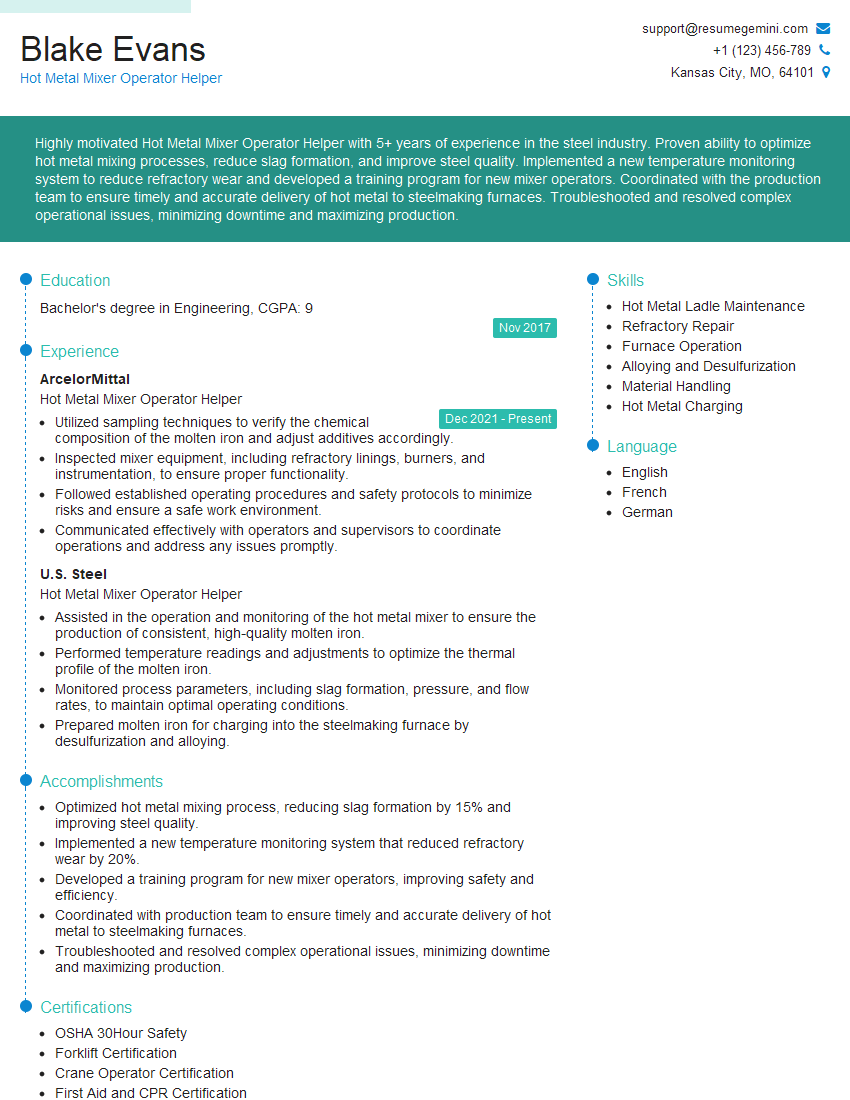

Blake Evans

Hot Metal Mixer Operator Helper

Summary

Highly motivated Hot Metal Mixer Operator Helper with 5+ years of experience in the steel industry. Proven ability to optimize hot metal mixing processes, reduce slag formation, and improve steel quality. Implemented a new temperature monitoring system to reduce refractory wear and developed a training program for new mixer operators. Coordinated with the production team to ensure timely and accurate delivery of hot metal to steelmaking furnaces. Troubleshooted and resolved complex operational issues, minimizing downtime and maximizing production.

Education

Bachelor’s degree in Engineering

November 2017

Skills

- Hot Metal Ladle Maintenance

- Refractory Repair

- Furnace Operation

- Alloying and Desulfurization

- Material Handling

- Hot Metal Charging

Work Experience

Hot Metal Mixer Operator Helper

- Utilized sampling techniques to verify the chemical composition of the molten iron and adjust additives accordingly.

- Inspected mixer equipment, including refractory linings, burners, and instrumentation, to ensure proper functionality.

- Followed established operating procedures and safety protocols to minimize risks and ensure a safe work environment.

- Communicated effectively with operators and supervisors to coordinate operations and address any issues promptly.

Hot Metal Mixer Operator Helper

- Assisted in the operation and monitoring of the hot metal mixer to ensure the production of consistent, high-quality molten iron.

- Performed temperature readings and adjustments to optimize the thermal profile of the molten iron.

- Monitored process parameters, including slag formation, pressure, and flow rates, to maintain optimal operating conditions.

- Prepared molten iron for charging into the steelmaking furnace by desulfurization and alloying.

Accomplishments

- Optimized hot metal mixing process, reducing slag formation by 15% and improving steel quality.

- Implemented a new temperature monitoring system that reduced refractory wear by 20%.

- Developed a training program for new mixer operators, improving safety and efficiency.

- Coordinated with production team to ensure timely and accurate delivery of hot metal to steelmaking furnaces.

- Troubleshooted and resolved complex operational issues, minimizing downtime and maximizing production.

Certificates

- OSHA 30Hour Safety

- Forklift Certification

- Crane Operator Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Metal Mixer Operator Helper

- Highlight your experience in optimizing hot metal mixing processes and improving steel quality.

- Quantify your accomplishments with specific metrics, such as reducing slag formation by 15% and improving refractory wear by 20%.

- Showcase your ability to troubleshoot and resolve complex operational issues.

- Demonstrate your knowledge of hot metal ladle maintenance, refractory repair, furnace operation, alloying and desulfurization, and material handling.

Essential Experience Highlights for a Strong Hot Metal Mixer Operator Helper Resume

- Optimized hot metal mixing process, reducing slag formation by 15% and improving steel quality.

- Implemented a new temperature monitoring system that reduced refractory wear by 20%.

- Developed a training program for new mixer operators, improving safety and efficiency.

- Coordinated with production team to ensure timely and accurate delivery of hot metal to steelmaking furnaces.

- Troubleshooted and resolved complex operational issues, minimizing downtime and maximizing production.

- Maintained and repaired hot metal ladles and refractory linings.

- Operated furnaces and controlled alloying and desulfurization processes.

Frequently Asked Questions (FAQ’s) For Hot Metal Mixer Operator Helper

What are the key responsibilities of a Hot Metal Mixer Operator Helper?

The key responsibilities of a Hot Metal Mixer Operator Helper include optimizing hot metal mixing processes, reducing slag formation, improving steel quality, implementing temperature monitoring systems, developing training programs for new mixer operators, coordinating with production teams, and troubleshooting complex operational issues.

What are the educational requirements for a Hot Metal Mixer Operator Helper?

A Hot Metal Mixer Operator Helper typically requires a high school diploma or equivalent, with some employers preferring candidates with a Bachelor’s degree in Engineering or a related field.

What skills are required for a Hot Metal Mixer Operator Helper?

Hot Metal Mixer Operator Helpers must have a strong understanding of hot metal mixing processes, refractory repair, furnace operation, alloying and desulfurization, and material handling.

What is the work environment of a Hot Metal Mixer Operator Helper like?

Hot Metal Mixer Operator Helpers typically work in a hot and noisy environment, often in close proximity to heavy machinery.

What is the career outlook for a Hot Metal Mixer Operator Helper?

The career outlook for Hot Metal Mixer Operator Helpers is expected to be good, with a projected 4% growth in employment over the next decade.

What are the salary expectations for a Hot Metal Mixer Operator Helper?

The salary expectations for a Hot Metal Mixer Operator Helper can vary depending on experience, location, and employer, but typically range from $50,000 to $80,000 per year.