Are you a seasoned Hot Metal Mixer Operator seeking a new career path? Discover our professionally built Hot Metal Mixer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

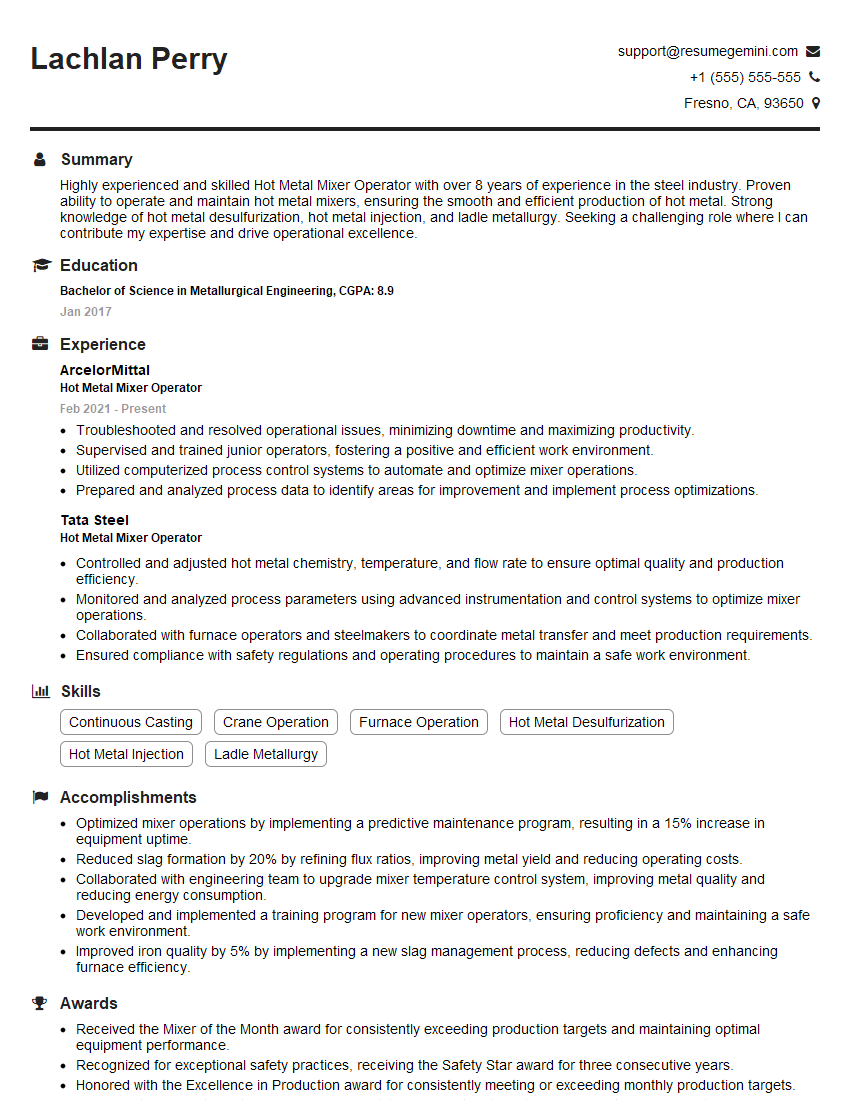

Lachlan Perry

Hot Metal Mixer Operator

Summary

Highly experienced and skilled Hot Metal Mixer Operator with over 8 years of experience in the steel industry. Proven ability to operate and maintain hot metal mixers, ensuring the smooth and efficient production of hot metal. Strong knowledge of hot metal desulfurization, hot metal injection, and ladle metallurgy. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor of Science in Metallurgical Engineering

January 2017

Skills

- Continuous Casting

- Crane Operation

- Furnace Operation

- Hot Metal Desulfurization

- Hot Metal Injection

- Ladle Metallurgy

Work Experience

Hot Metal Mixer Operator

- Troubleshooted and resolved operational issues, minimizing downtime and maximizing productivity.

- Supervised and trained junior operators, fostering a positive and efficient work environment.

- Utilized computerized process control systems to automate and optimize mixer operations.

- Prepared and analyzed process data to identify areas for improvement and implement process optimizations.

Hot Metal Mixer Operator

- Controlled and adjusted hot metal chemistry, temperature, and flow rate to ensure optimal quality and production efficiency.

- Monitored and analyzed process parameters using advanced instrumentation and control systems to optimize mixer operations.

- Collaborated with furnace operators and steelmakers to coordinate metal transfer and meet production requirements.

- Ensured compliance with safety regulations and operating procedures to maintain a safe work environment.

Accomplishments

- Optimized mixer operations by implementing a predictive maintenance program, resulting in a 15% increase in equipment uptime.

- Reduced slag formation by 20% by refining flux ratios, improving metal yield and reducing operating costs.

- Collaborated with engineering team to upgrade mixer temperature control system, improving metal quality and reducing energy consumption.

- Developed and implemented a training program for new mixer operators, ensuring proficiency and maintaining a safe work environment.

- Improved iron quality by 5% by implementing a new slag management process, reducing defects and enhancing furnace efficiency.

Awards

- Received the Mixer of the Month award for consistently exceeding production targets and maintaining optimal equipment performance.

- Recognized for exceptional safety practices, receiving the Safety Star award for three consecutive years.

- Honored with the Excellence in Production award for consistently meeting or exceeding monthly production targets.

- Received the Operator of the Year award for outstanding contributions to mixer operations and plant performance.

Certificates

- National Association of Steel Producers (NASP) Level 3 Hot Metal Mixer Operator Certification

- International Association of Iron and Steel Engineers (IAISE) Hot Metal Mixer Operator Certification

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Commissioned Boiler Operator Certification

- Occupational Safety and Health Administration (OSHA) 10Hour Safety Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Metal Mixer Operator

- Highlight your experience and skills in hot metal mixer operation, desulfurization, and ladle metallurgy.

- Quantify your accomplishments and provide specific examples of how you have improved productivity or reduced downtime.

- Demonstrate your knowledge of safety protocols and procedures for working in a hazardous environment.

- Include a section in your resume that showcases your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Hot Metal Mixer Operator Resume

- Operate and maintain hot metal mixers, including charging, mixing, and tapping operations.

- Monitor and control mixer temperature, chemistry, and flow rates to ensure product quality.

- Perform hot metal desulfurization and hot metal injection to remove impurities and adjust composition.

- Conduct ladle metallurgy operations to adjust the chemical composition of the hot metal.

- Monitor and troubleshoot mixer equipment and systems to prevent breakdowns and ensure safe operation.

- Work closely with other operators and supervisors to coordinate production and maintain plant efficiency.

Frequently Asked Questions (FAQ’s) For Hot Metal Mixer Operator

What is the primary role of a Hot Metal Mixer Operator?

The primary role of a Hot Metal Mixer Operator is to operate and maintain hot metal mixers, which are used to homogenize the temperature and composition of molten iron before it is transferred to other steelmaking processes.

What are the key skills required for a Hot Metal Mixer Operator?

Key skills for a Hot Metal Mixer Operator include proficiency in hot metal mixer operation, desulfurization, and ladle metallurgy, as well as a strong understanding of iron and steelmaking processes, and the ability to work in a hazardous environment.

What is the career outlook for Hot Metal Mixer Operators?

The career outlook for Hot Metal Mixer Operators is expected to be stable, with a projected growth of around 4% from 2021 to 2031, primarily driven by the increasing demand for steel in various industries.

What are the safety requirements for Hot Metal Mixer Operators?

Hot Metal Mixer Operators must adhere to strict safety protocols and procedures, including wearing protective clothing and equipment, maintaining a clean work area, and following proper lockout/tagout procedures to prevent accidents and injuries.

What is the average salary for Hot Metal Mixer Operators?

The average salary for Hot Metal Mixer Operators in the United States is around $85,000 per year, although this can vary depending on factors such as experience, location, and company size.

What are the different types of hot metal mixers used in the steel industry?

Common types of hot metal mixers used in the steel industry include torpedo mixers, vertical mixers, and inline mixers, each with its own advantages and applications in the production of hot metal.

What are the challenges faced by Hot Metal Mixer Operators?

Challenges faced by Hot Metal Mixer Operators include working in a hazardous environment with molten metal, maintaining a consistent and optimal mixer operation, and troubleshooting and resolving technical issues that may arise during the mixing process.