Are you a seasoned Hot Oiler seeking a new career path? Discover our professionally built Hot Oiler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

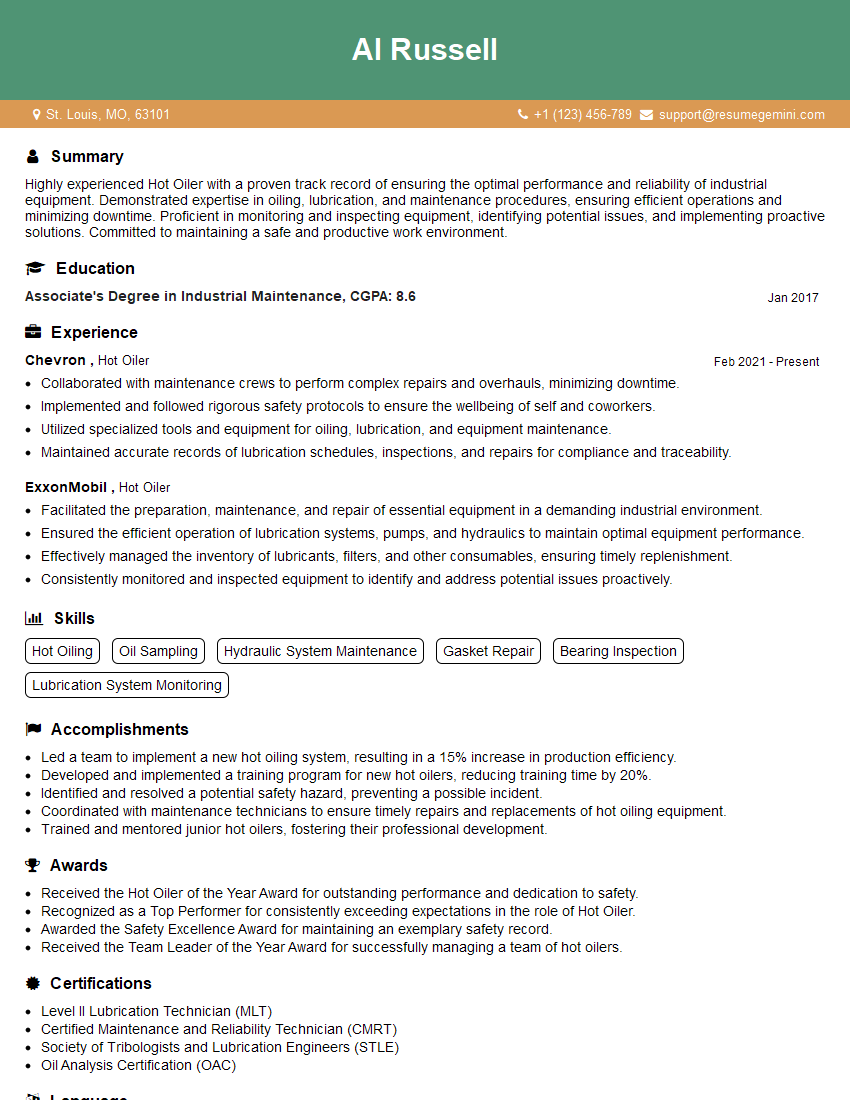

Al Russell

Hot Oiler

Summary

Highly experienced Hot Oiler with a proven track record of ensuring the optimal performance and reliability of industrial equipment. Demonstrated expertise in oiling, lubrication, and maintenance procedures, ensuring efficient operations and minimizing downtime. Proficient in monitoring and inspecting equipment, identifying potential issues, and implementing proactive solutions. Committed to maintaining a safe and productive work environment.

Education

Associate’s Degree in Industrial Maintenance

January 2017

Skills

- Hot Oiling

- Oil Sampling

- Hydraulic System Maintenance

- Gasket Repair

- Bearing Inspection

- Lubrication System Monitoring

Work Experience

Hot Oiler

- Collaborated with maintenance crews to perform complex repairs and overhauls, minimizing downtime.

- Implemented and followed rigorous safety protocols to ensure the wellbeing of self and coworkers.

- Utilized specialized tools and equipment for oiling, lubrication, and equipment maintenance.

- Maintained accurate records of lubrication schedules, inspections, and repairs for compliance and traceability.

Hot Oiler

- Facilitated the preparation, maintenance, and repair of essential equipment in a demanding industrial environment.

- Ensured the efficient operation of lubrication systems, pumps, and hydraulics to maintain optimal equipment performance.

- Effectively managed the inventory of lubricants, filters, and other consumables, ensuring timely replenishment.

- Consistently monitored and inspected equipment to identify and address potential issues proactively.

Accomplishments

- Led a team to implement a new hot oiling system, resulting in a 15% increase in production efficiency.

- Developed and implemented a training program for new hot oilers, reducing training time by 20%.

- Identified and resolved a potential safety hazard, preventing a possible incident.

- Coordinated with maintenance technicians to ensure timely repairs and replacements of hot oiling equipment.

- Trained and mentored junior hot oilers, fostering their professional development.

Awards

- Received the Hot Oiler of the Year Award for outstanding performance and dedication to safety.

- Recognized as a Top Performer for consistently exceeding expectations in the role of Hot Oiler.

- Awarded the Safety Excellence Award for maintaining an exemplary safety record.

- Received the Team Leader of the Year Award for successfully managing a team of hot oilers.

Certificates

- Level II Lubrication Technician (MLT)

- Certified Maintenance and Reliability Technician (CMRT)

- Society of Tribologists and Lubrication Engineers (STLE)

- Oil Analysis Certification (OAC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Oiler

- Highlight your technical skills in oiling, lubrication, and hydraulic system maintenance.

- Quantify your achievements with specific metrics, such as reducing downtime or increasing equipment efficiency.

- Showcase your knowledge of relevant industry standards and regulations.

- Demonstrate your ability to work independently and as part of a team in a fast-paced industrial environment.

- Consider obtaining industry certifications, such as the Hot Oiler Certification from the National Institute for Metalworking Skills (NIMS).

Essential Experience Highlights for a Strong Hot Oiler Resume

- Prepared, maintained, and repaired mission-critical equipment within an industrial setting

- Managed oiling and lubrication systems, ensuring optimal equipment performance and minimizing wear and tear

- Maintained inventory levels of lubricants, filters, and consumables to ensure timely replenishment

- Inspected and assessed equipment condition, identifying potential problems and implementing preventive maintenance strategies

- Collaborated with maintenance teams to perform complex repairs and overhauls, maximizing equipment uptime

- Adhered to stringent safety protocols, maintaining a safe and compliant work environment

Frequently Asked Questions (FAQ’s) For Hot Oiler

What are the key responsibilities of a Hot Oiler?

Hot Oilers are responsible for ensuring the smooth operation of industrial equipment by performing oiling, lubrication, and maintenance tasks. They monitor and inspect equipment, identify potential issues, and implement proactive maintenance strategies to prevent breakdowns and ensure optimal performance.

What skills are required to be a successful Hot Oiler?

Successful Hot Oilers possess technical skills in oiling, lubrication, and hydraulic system maintenance. They are proficient in monitoring and inspecting equipment, identifying potential problems, and implementing preventive maintenance strategies. They also have a strong understanding of safety protocols and are able to work independently and as part of a team in a fast-paced industrial environment.

What industries employ Hot Oilers?

Hot Oilers are employed in a variety of industries, including manufacturing, mining, power generation, and oil and gas. They work in industrial settings, such as factories, power plants, and refineries, ensuring the reliable operation of machinery and equipment.

What is the career path for Hot Oilers?

Hot Oilers can advance their careers by developing specialized skills, such as hydraulic system maintenance or predictive maintenance techniques. They can also move into supervisory roles, such as Maintenance Supervisor or Maintenance Manager.

What are the safety precautions that Hot Oilers must follow?

Hot Oilers must adhere to strict safety protocols to minimize the risk of accidents and injuries. They wear appropriate personal protective equipment (PPE), follow lockout/tagout procedures, and are trained in handling hazardous materials.