Are you a seasoned Hot Stamp Operator seeking a new career path? Discover our professionally built Hot Stamp Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

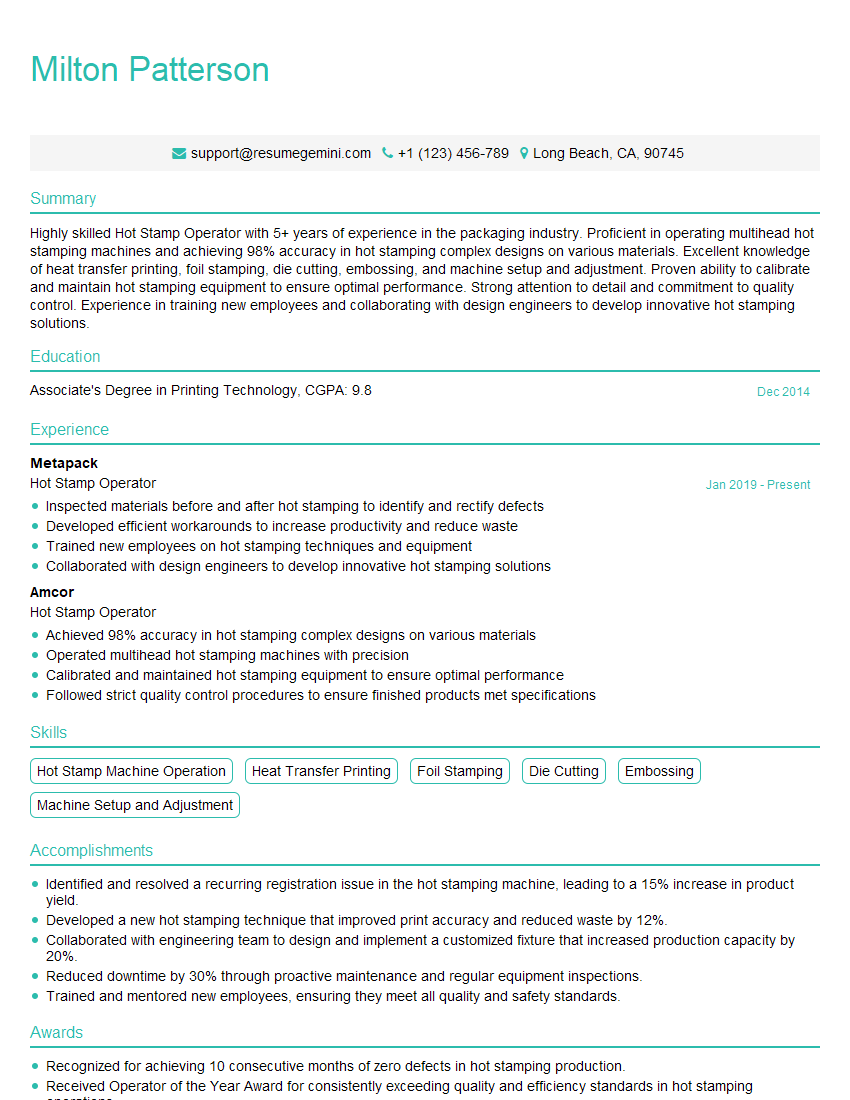

Milton Patterson

Hot Stamp Operator

Summary

Highly skilled Hot Stamp Operator with 5+ years of experience in the packaging industry. Proficient in operating multihead hot stamping machines and achieving 98% accuracy in hot stamping complex designs on various materials. Excellent knowledge of heat transfer printing, foil stamping, die cutting, embossing, and machine setup and adjustment. Proven ability to calibrate and maintain hot stamping equipment to ensure optimal performance. Strong attention to detail and commitment to quality control. Experience in training new employees and collaborating with design engineers to develop innovative hot stamping solutions.

Education

Associate’s Degree in Printing Technology

December 2014

Skills

- Hot Stamp Machine Operation

- Heat Transfer Printing

- Foil Stamping

- Die Cutting

- Embossing

- Machine Setup and Adjustment

Work Experience

Hot Stamp Operator

- Inspected materials before and after hot stamping to identify and rectify defects

- Developed efficient workarounds to increase productivity and reduce waste

- Trained new employees on hot stamping techniques and equipment

- Collaborated with design engineers to develop innovative hot stamping solutions

Hot Stamp Operator

- Achieved 98% accuracy in hot stamping complex designs on various materials

- Operated multihead hot stamping machines with precision

- Calibrated and maintained hot stamping equipment to ensure optimal performance

- Followed strict quality control procedures to ensure finished products met specifications

Accomplishments

- Identified and resolved a recurring registration issue in the hot stamping machine, leading to a 15% increase in product yield.

- Developed a new hot stamping technique that improved print accuracy and reduced waste by 12%.

- Collaborated with engineering team to design and implement a customized fixture that increased production capacity by 20%.

- Reduced downtime by 30% through proactive maintenance and regular equipment inspections.

- Trained and mentored new employees, ensuring they meet all quality and safety standards.

Awards

- Recognized for achieving 10 consecutive months of zero defects in hot stamping production.

- Received Operator of the Year Award for consistently exceeding quality and efficiency standards in hot stamping operations.

- Awarded Certificate of Excellence for innovative process improvement that reduced production time by 25%.

- Won a safety award for maintaining a spotless safety record in the hot stamping department for three consecutive years.

Certificates

- Hot Stamp Application Specialist (HAS)

- Certified Hot Stamp Operator (CHSO)

- FOGRA Certified Color Expert (FCE)

- ISO 9001 Quality Management System Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Stamp Operator

- Highlight your accuracy and precision in hot stamping complex designs.

- Quantify your achievements whenever possible, such as increasing productivity by a certain percentage or reducing waste by a certain amount.

- Emphasize your knowledge of heat transfer printing, foil stamping, die cutting, embossing, and machine setup and adjustment.

- Showcase your ability to calibrate and maintain hot stamping equipment to ensure optimal performance.

- Demonstrate your commitment to quality control and attention to detail.

Essential Experience Highlights for a Strong Hot Stamp Operator Resume

- Operate multihead hot stamping machines with precision and achieve 98% accuracy in hot stamping complex designs on various materials.

- Calibrate and maintain hot stamping equipment to ensure optimal performance.

- Follow strict quality control procedures to ensure finished products meet specifications.

- Inspect materials before and after hot stamping to identify and rectify defects.

- Develop efficient workarounds to increase productivity and reduce waste.

- Train new employees on hot stamping techniques and equipment.

- Collaborate with design engineers to develop innovative hot stamping solutions.

Frequently Asked Questions (FAQ’s) For Hot Stamp Operator

What is hot stamping?

Hot stamping is a printing process that uses heat and pressure to transfer metallic or colored foil onto a material. It is often used to add logos, designs, or lettering to packaging, labels, and other products.

What are the different types of hot stamping machines?

There are two main types of hot stamping machines: flatbed and rotary. Flatbed machines are used for small to medium-sized items, while rotary machines are used for large-volume production.

What materials can be hot stamped?

Hot stamping can be used on a variety of materials, including paper, plastic, metal, and leather.

What are the benefits of hot stamping?

Hot stamping offers a number of benefits, including durability, high quality, and a wide range of design options.

What are the challenges of hot stamping?

Hot stamping can be a challenging process, as it requires precision and attention to detail. It is also important to use the correct materials and equipment to achieve the desired results.

What are the career opportunities for hot stamp operators?

Hot stamp operators can find work in a variety of industries, including packaging, printing, and manufacturing. There are also opportunities for advancement to supervisory and management positions.