Are you a seasoned Hydraulic Pressure Auto Frettage Machine Operator seeking a new career path? Discover our professionally built Hydraulic Pressure Auto Frettage Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

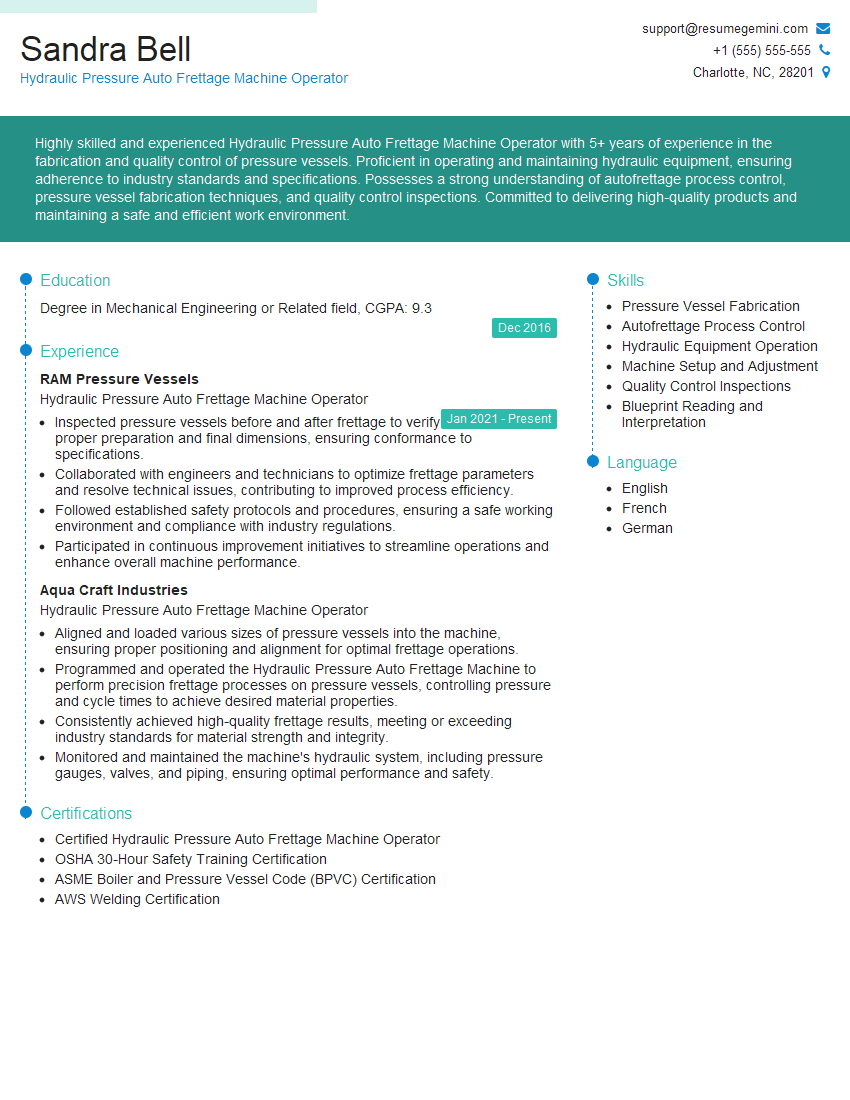

Sandra Bell

Hydraulic Pressure Auto Frettage Machine Operator

Summary

Highly skilled and experienced Hydraulic Pressure Auto Frettage Machine Operator with 5+ years of experience in the fabrication and quality control of pressure vessels. Proficient in operating and maintaining hydraulic equipment, ensuring adherence to industry standards and specifications. Possesses a strong understanding of autofrettage process control, pressure vessel fabrication techniques, and quality control inspections. Committed to delivering high-quality products and maintaining a safe and efficient work environment.

Education

Degree in Mechanical Engineering or Related field

December 2016

Skills

- Pressure Vessel Fabrication

- Autofrettage Process Control

- Hydraulic Equipment Operation

- Machine Setup and Adjustment

- Quality Control Inspections

- Blueprint Reading and Interpretation

Work Experience

Hydraulic Pressure Auto Frettage Machine Operator

- Inspected pressure vessels before and after frettage to verify proper preparation and final dimensions, ensuring conformance to specifications.

- Collaborated with engineers and technicians to optimize frettage parameters and resolve technical issues, contributing to improved process efficiency.

- Followed established safety protocols and procedures, ensuring a safe working environment and compliance with industry regulations.

- Participated in continuous improvement initiatives to streamline operations and enhance overall machine performance.

Hydraulic Pressure Auto Frettage Machine Operator

- Aligned and loaded various sizes of pressure vessels into the machine, ensuring proper positioning and alignment for optimal frettage operations.

- Programmed and operated the Hydraulic Pressure Auto Frettage Machine to perform precision frettage processes on pressure vessels, controlling pressure and cycle times to achieve desired material properties.

- Consistently achieved high-quality frettage results, meeting or exceeding industry standards for material strength and integrity.

- Monitored and maintained the machine’s hydraulic system, including pressure gauges, valves, and piping, ensuring optimal performance and safety.

Certificates

- Certified Hydraulic Pressure Auto Frettage Machine Operator

- OSHA 30-Hour Safety Training Certification

- ASME Boiler and Pressure Vessel Code (BPVC) Certification

- AWS Welding Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydraulic Pressure Auto Frettage Machine Operator

- Highlight your experience and expertise in hydraulic pressure auto frettage machine operation and maintenance.

- Showcase your understanding of autofrettage process control, pressure vessel fabrication techniques, and quality control inspections.

- Quantify your accomplishments and provide specific examples of how you contributed to improving quality and efficiency.

- Demonstrate your commitment to safety and compliance with industry standards and regulations.

Essential Experience Highlights for a Strong Hydraulic Pressure Auto Frettage Machine Operator Resume

- Operate and maintain hydraulic pressure auto frettage machines, ensuring optimal performance and efficiency.

- Control and monitor autofrettage process parameters, including pressure, temperature, and time, to achieve desired results.

- Ensure proper setup and adjustment of machines, utilizing blueprints and technical drawings.

- Perform quality control inspections on finished pressure vessels, verifying dimensions, surface finish, and overall quality.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

- Collaborate with engineers and quality assurance personnel to resolve technical issues and improve processes.

Frequently Asked Questions (FAQ’s) For Hydraulic Pressure Auto Frettage Machine Operator

What is the role of a Hydraulic Pressure Auto Frettage Machine Operator?

A Hydraulic Pressure Auto Frettage Machine Operator is responsible for operating and maintaining hydraulic pressure auto frettage machines, controlling autofrettage process parameters, performing quality control inspections, and ensuring proper setup and adjustment of machines.

What skills are required to be a successful Hydraulic Pressure Auto Frettage Machine Operator?

Successful Hydraulic Pressure Auto Frettage Machine Operators possess expertise in pressure vessel fabrication, autofrettage process control, hydraulic equipment operation, machine setup and adjustment, quality control inspections, and blueprint reading and interpretation.

What are the key responsibilities of a Hydraulic Pressure Auto Frettage Machine Operator?

Key responsibilities include operating and maintaining hydraulic pressure auto frettage machines, controlling autofrettage process parameters, performing quality control inspections, ensuring proper machine setup and adjustment, and adhering to safety protocols.

What qualifications are required to become a Hydraulic Pressure Auto Frettage Machine Operator?

Typically, a Degree in Mechanical Engineering or a related field is required, along with experience in pressure vessel fabrication and quality control.

What is the career outlook for Hydraulic Pressure Auto Frettage Machine Operators?

The career outlook is positive, as there is a growing demand for skilled operators in the pressure vessel fabrication industry.