Are you a seasoned Hydroelectric Component Machinist seeking a new career path? Discover our professionally built Hydroelectric Component Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

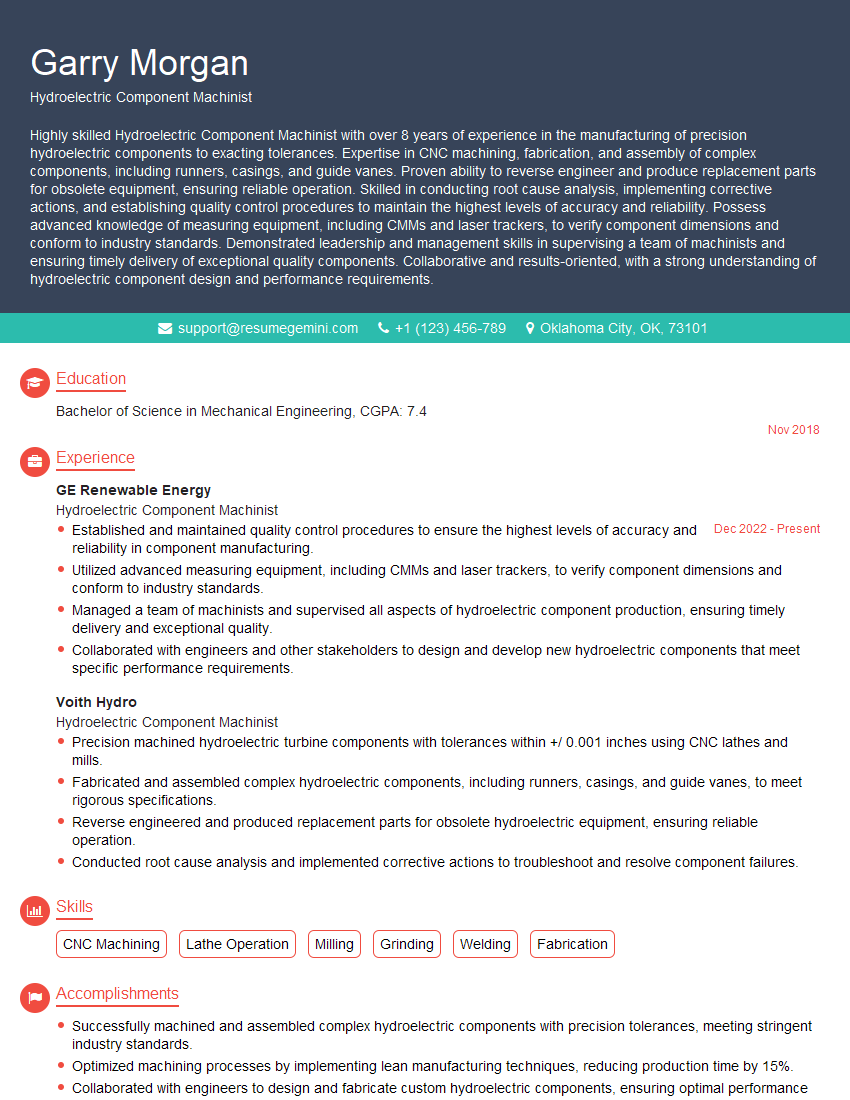

Garry Morgan

Hydroelectric Component Machinist

Summary

Highly skilled Hydroelectric Component Machinist with over 8 years of experience in the manufacturing of precision hydroelectric components to exacting tolerances. Expertise in CNC machining, fabrication, and assembly of complex components, including runners, casings, and guide vanes. Proven ability to reverse engineer and produce replacement parts for obsolete equipment, ensuring reliable operation. Skilled in conducting root cause analysis, implementing corrective actions, and establishing quality control procedures to maintain the highest levels of accuracy and reliability. Possess advanced knowledge of measuring equipment, including CMMs and laser trackers, to verify component dimensions and conform to industry standards. Demonstrated leadership and management skills in supervising a team of machinists and ensuring timely delivery of exceptional quality components. Collaborative and results-oriented, with a strong understanding of hydroelectric component design and performance requirements.

Education

Bachelor of Science in Mechanical Engineering

November 2018

Skills

- CNC Machining

- Lathe Operation

- Milling

- Grinding

- Welding

- Fabrication

Work Experience

Hydroelectric Component Machinist

- Established and maintained quality control procedures to ensure the highest levels of accuracy and reliability in component manufacturing.

- Utilized advanced measuring equipment, including CMMs and laser trackers, to verify component dimensions and conform to industry standards.

- Managed a team of machinists and supervised all aspects of hydroelectric component production, ensuring timely delivery and exceptional quality.

- Collaborated with engineers and other stakeholders to design and develop new hydroelectric components that meet specific performance requirements.

Hydroelectric Component Machinist

- Precision machined hydroelectric turbine components with tolerances within +/ 0.001 inches using CNC lathes and mills.

- Fabricated and assembled complex hydroelectric components, including runners, casings, and guide vanes, to meet rigorous specifications.

- Reverse engineered and produced replacement parts for obsolete hydroelectric equipment, ensuring reliable operation.

- Conducted root cause analysis and implemented corrective actions to troubleshoot and resolve component failures.

Accomplishments

- Successfully machined and assembled complex hydroelectric components with precision tolerances, meeting stringent industry standards.

- Optimized machining processes by implementing lean manufacturing techniques, reducing production time by 15%.

- Collaborated with engineers to design and fabricate custom hydroelectric components, ensuring optimal performance and reliability.

- Troubleshooted and repaired complex hydroelectric machinery, minimizing downtime and ensuring smooth operations.

- Developed a training program for new employees, enhancing their knowledge and skills in hydroelectric component machining.

Awards

- Received the Employee of the Year Award for outstanding contributions to the hydroelectric component machining department.

- Recognized with the Safety Excellence Award for exceptional adherence to safety protocols in the machining of hydroelectric components.

- Awarded the Innovation Award for developing a new technique to improve the efficiency of machining hydroelectric components.

Certificates

- Certified Machinist

- Certified Welder

- OSHA Safety Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydroelectric Component Machinist

Highlight your precision machining skills and experience.

Hydroelectric components are critical to the efficient operation of hydroelectric power plants, so employers will be looking for candidates with a proven track record of producing high-quality parts to exacting tolerances.Quantify your accomplishments.

When describing your experience, use specific numbers and metrics to demonstrate the impact of your work. For example, you might say that you “reduced production time by 15%” or “improved product quality by 20%”.Demonstrate your knowledge of hydroelectric systems.

Employers will want to know that you have a good understanding of how hydroelectric power plants operate and the role that components play in that process.Be prepared to discuss your safety record.

Hydroelectric power plants are inherently dangerous environments, so employers will want to know that you have a strong safety record and are committed to working safely.Get certified.

There are a number of industry certifications that can demonstrate your skills and knowledge as a Hydroelectric Component Machinist. Earning one or more of these certifications can make you a more competitive candidate for jobs.

Essential Experience Highlights for a Strong Hydroelectric Component Machinist Resume

- Precision machined hydroelectric turbine components with tolerances within +/- 0.001 inches using CNC lathes and mills.

- Fabricated and assembled complex hydroelectric components, including runners, casings, and guide vanes, to meet rigorous specifications.

- Reverse engineered and produced replacement parts for obsolete hydroelectric equipment, ensuring reliable operation.

- Conducted root cause analysis and implemented corrective actions to troubleshoot and resolve component failures.

- Established and maintained quality control procedures to ensure the highest levels of accuracy and reliability in component manufacturing.

- Utilized advanced measuring equipment, including CMMs and laser trackers, to verify component dimensions and conform to industry standards.

- Managed a team of machinists and supervised all aspects of hydroelectric component production, ensuring timely delivery and exceptional quality.

Frequently Asked Questions (FAQ’s) For Hydroelectric Component Machinist

What is a Hydroelectric Component Machinist?

A Hydroelectric Component Machinist is a skilled professional who manufactures and repairs components used in hydroelectric power plants. These components include runners, casings, guide vanes, and other parts that are essential for the efficient operation of the plant.

What are the job duties of a Hydroelectric Component Machinist?

The job duties of a Hydroelectric Component Machinist include precision machining of components to exacting tolerances, fabrication and assembly of complex components, reverse engineering and production of replacement parts, conducting root cause analysis and implementing corrective actions, and establishing and maintaining quality control procedures.

What are the qualifications for a Hydroelectric Component Machinist?

The qualifications for a Hydroelectric Component Machinist typically include a high school diploma or equivalent, as well as several years of experience in the machining industry. Additional qualifications may include a college degree in mechanical engineering or a related field, as well as certification in relevant machining processes.

What is the work environment of a Hydroelectric Component Machinist?

The work environment of a Hydroelectric Component Machinist is typically a machine shop or manufacturing facility. The work can be physically demanding and may require working in awkward or confined spaces. Hydroelectric Component Machinists must also be able to work independently and as part of a team.

What is the career outlook for Hydroelectric Component Machinists?

The career outlook for Hydroelectric Component Machinists is expected to be good over the next few years. The demand for hydroelectric power is increasing, and this is expected to lead to increased demand for Hydroelectric Component Machinists.

What are the earning prospects for Hydroelectric Component Machinists?

The earning prospects for Hydroelectric Component Machinists vary depending on experience, location, and employer. However, Hydroelectric Component Machinists with several years of experience can earn a good living.

What are the benefits of working as a Hydroelectric Component Machinist?

The benefits of working as a Hydroelectric Component Machinist include a good salary, job security, and the opportunity to work in a challenging and rewarding field.