Are you a seasoned Hydropress Operator seeking a new career path? Discover our professionally built Hydropress Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

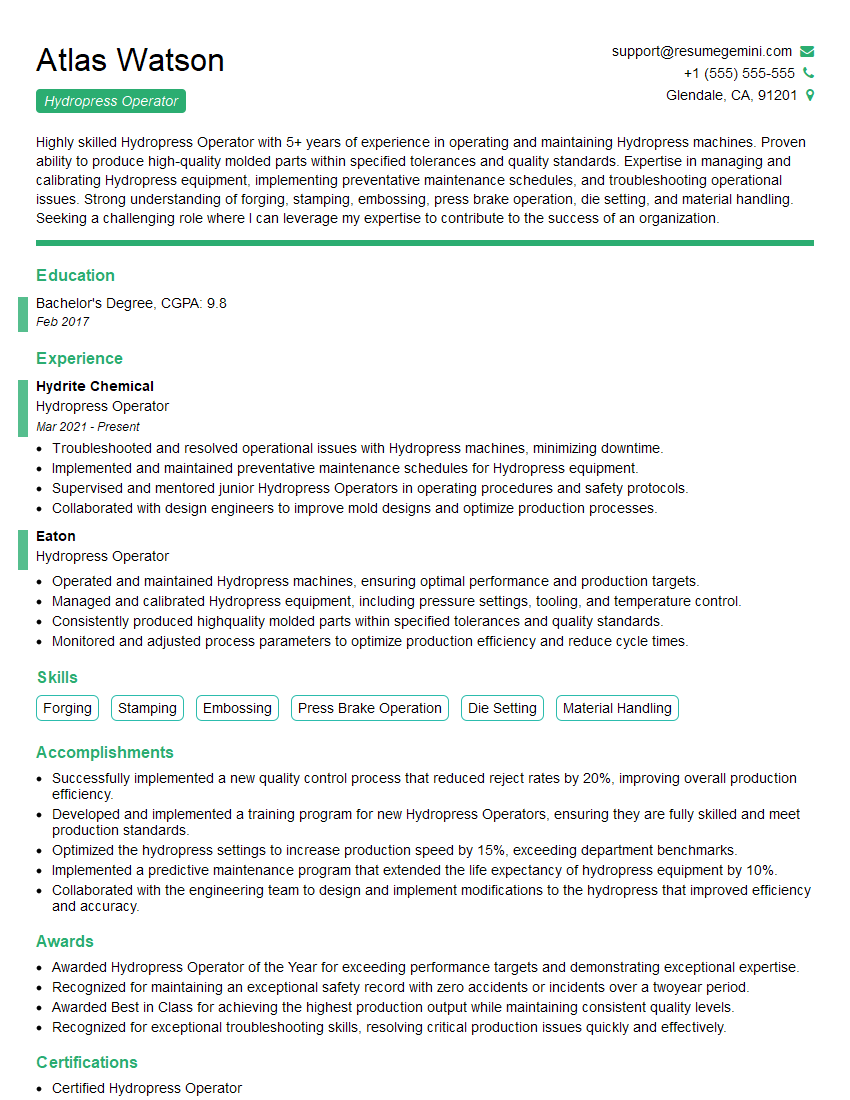

Atlas Watson

Hydropress Operator

Summary

Highly skilled Hydropress Operator with 5+ years of experience in operating and maintaining Hydropress machines. Proven ability to produce high-quality molded parts within specified tolerances and quality standards. Expertise in managing and calibrating Hydropress equipment, implementing preventative maintenance schedules, and troubleshooting operational issues. Strong understanding of forging, stamping, embossing, press brake operation, die setting, and material handling. Seeking a challenging role where I can leverage my expertise to contribute to the success of an organization.

Education

Bachelor’s Degree

February 2017

Skills

- Forging

- Stamping

- Embossing

- Press Brake Operation

- Die Setting

- Material Handling

Work Experience

Hydropress Operator

- Troubleshooted and resolved operational issues with Hydropress machines, minimizing downtime.

- Implemented and maintained preventative maintenance schedules for Hydropress equipment.

- Supervised and mentored junior Hydropress Operators in operating procedures and safety protocols.

- Collaborated with design engineers to improve mold designs and optimize production processes.

Hydropress Operator

- Operated and maintained Hydropress machines, ensuring optimal performance and production targets.

- Managed and calibrated Hydropress equipment, including pressure settings, tooling, and temperature control.

- Consistently produced highquality molded parts within specified tolerances and quality standards.

- Monitored and adjusted process parameters to optimize production efficiency and reduce cycle times.

Accomplishments

- Successfully implemented a new quality control process that reduced reject rates by 20%, improving overall production efficiency.

- Developed and implemented a training program for new Hydropress Operators, ensuring they are fully skilled and meet production standards.

- Optimized the hydropress settings to increase production speed by 15%, exceeding department benchmarks.

- Implemented a predictive maintenance program that extended the life expectancy of hydropress equipment by 10%.

- Collaborated with the engineering team to design and implement modifications to the hydropress that improved efficiency and accuracy.

Awards

- Awarded Hydropress Operator of the Year for exceeding performance targets and demonstrating exceptional expertise.

- Recognized for maintaining an exceptional safety record with zero accidents or incidents over a twoyear period.

- Awarded Best in Class for achieving the highest production output while maintaining consistent quality levels.

- Recognized for exceptional troubleshooting skills, resolving critical production issues quickly and effectively.

Certificates

- Certified Hydropress Operator

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Quality Inspector (CQI)

- OSHA 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydropress Operator

- Highlight your experience and skills in operating and maintaining Hydropress machines.

- Showcase your ability to produce high-quality molded parts within specified tolerances and quality standards.

- Emphasize your troubleshooting and problem-solving abilities as they are crucial for Hydropress Operators.

- Include any certifications or training related to Hydropress operation and maintenance.

Essential Experience Highlights for a Strong Hydropress Operator Resume

- Operate and maintain Hydropress machines, ensuring optimal performance and production targets.

- Manage and calibrate Hydropress equipment, including pressure settings, tooling, and temperature control.

- Consistently produce high-quality molded parts within specified tolerances and quality standards.

- Monitor and adjust process parameters to optimize production efficiency and reduce cycle times.

- Troubleshoot and resolve operational issues with Hydropress machines, minimizing downtime.

- Implement and maintain preventative maintenance schedules for Hydropress equipment.

- Supervise and mentor junior Hydropress Operators in operating procedures and safety protocols.

Frequently Asked Questions (FAQ’s) For Hydropress Operator

What is a Hydropress?

A Hydropress is a machine that uses high-pressure water to form and shape materials.

What are the key responsibilities of a Hydropress Operator?

Operating and maintaining Hydropress machines, producing high-quality molded parts, troubleshooting operational issues, and implementing preventative maintenance.

What skills are required to be a successful Hydropress Operator?

Experience in operating and maintaining Hydropress machines, knowledge of forging, stamping, embossing, press brake operation, die setting, and material handling.

What industries use Hydropress machines?

Automotive, aerospace, construction, and manufacturing.

What is the career outlook for Hydropress Operators?

The job outlook is expected to grow in the coming years due to increasing demand for molded parts in various industries.

What is the average salary of a Hydropress Operator?

The average salary varies based on experience, location, and industry.

What are the safety precautions to consider when working with Hydropress machines?

Always follow the manufacturer’s guidelines, wear appropriate safety gear, and be aware of potential hazards.