Are you a seasoned Incising Machine Operator seeking a new career path? Discover our professionally built Incising Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

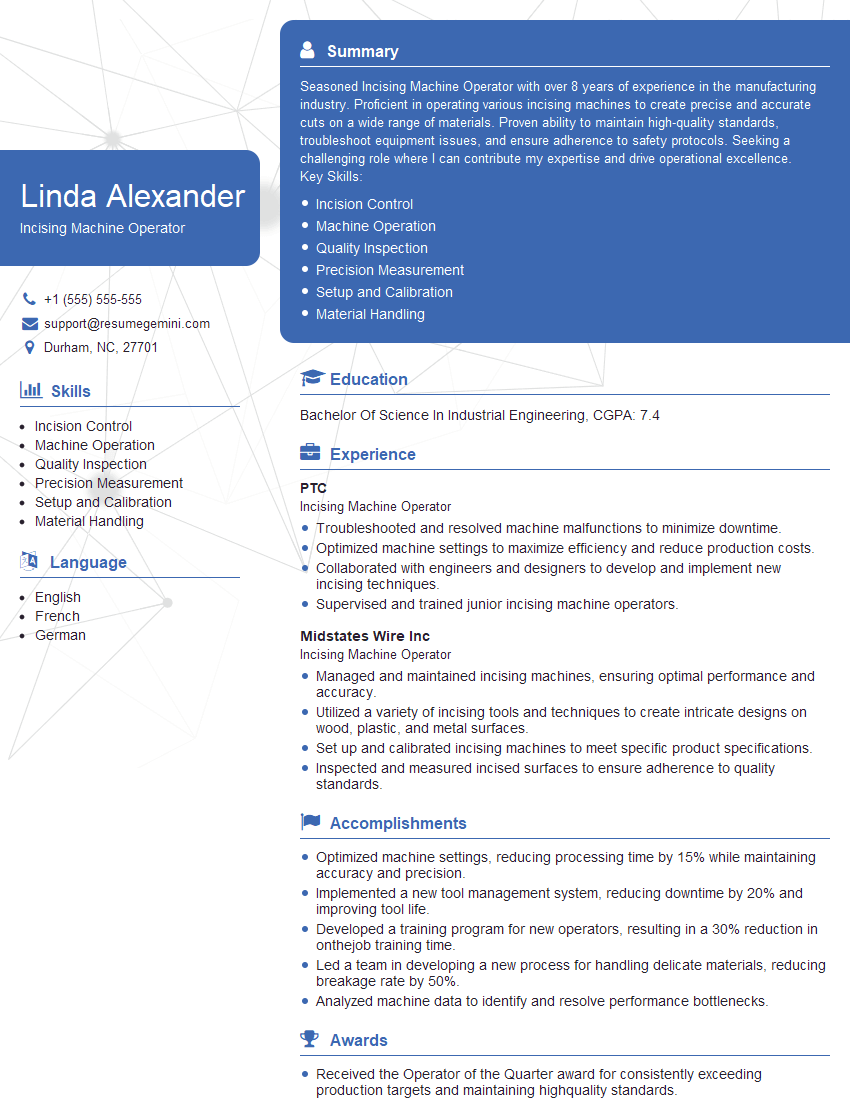

Linda Alexander

Incising Machine Operator

Summary

Seasoned Incising Machine Operator with over 8 years of experience in the manufacturing industry. Proficient in operating various incising machines to create precise and accurate cuts on a wide range of materials. Proven ability to maintain high-quality standards, troubleshoot equipment issues, and ensure adherence to safety protocols. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Key Skills:

- Incision Control

- Machine Operation

- Quality Inspection

- Precision Measurement

- Setup and Calibration

- Material Handling

Education

Bachelor Of Science In Industrial Engineering

January 2015

Skills

- Incision Control

- Machine Operation

- Quality Inspection

- Precision Measurement

- Setup and Calibration

- Material Handling

Work Experience

Incising Machine Operator

- Troubleshooted and resolved machine malfunctions to minimize downtime.

- Optimized machine settings to maximize efficiency and reduce production costs.

- Collaborated with engineers and designers to develop and implement new incising techniques.

- Supervised and trained junior incising machine operators.

Incising Machine Operator

- Managed and maintained incising machines, ensuring optimal performance and accuracy.

- Utilized a variety of incising tools and techniques to create intricate designs on wood, plastic, and metal surfaces.

- Set up and calibrated incising machines to meet specific product specifications.

- Inspected and measured incised surfaces to ensure adherence to quality standards.

Accomplishments

- Optimized machine settings, reducing processing time by 15% while maintaining accuracy and precision.

- Implemented a new tool management system, reducing downtime by 20% and improving tool life.

- Developed a training program for new operators, resulting in a 30% reduction in onthejob training time.

- Led a team in developing a new process for handling delicate materials, reducing breakage rate by 50%.

- Analyzed machine data to identify and resolve performance bottlenecks.

Awards

- Received the Operator of the Quarter award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for exceptional teamwork and collaboration in resolving production issues.

- Certified as a Master Incising Machine Operator by the National Incising Machine Association.

- Received a Safety Excellence Award for maintaining a spotless safety record.

Certificates

- Incising Machine Operator Level I

- Incising Machine Operator Level II

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Incising Machine Operator

- Quantify your accomplishments: Use specific numbers and metrics to showcase your impact on the job.

- Highlight your attention to detail: Emphasize your ability to produce precise and accurate incisions.

- Demonstrate your problem-solving skills: Provide examples of how you have resolved technical issues and improved processes.

- Showcase your commitment to safety: Highlight your adherence to safety protocols and your role in maintaining a safe work environment.

- Consider including a portfolio: If possible, create a portfolio of your work to showcase the quality of your incisions.

Essential Experience Highlights for a Strong Incising Machine Operator Resume

- Set up and calibrate incising machines according to specified parameters.

- Load and position materials accurately for precise incisions.

- Operate incising machines to create clean and consistent cuts on various materials.

- Monitor and maintain incision quality, ensuring compliance with established standards.

- Perform regular maintenance and troubleshooting of machines to minimize downtime.

- Adhere to safety protocols and follow established operating procedures.

- Collaborate with production teams to resolve technical issues and improve efficiency.

Frequently Asked Questions (FAQ’s) For Incising Machine Operator

What are the key skills required to be an effective Incising Machine Operator?

Effective Incising Machine Operators must possess a combination of technical skills, including incision control, machine operation, quality inspection, precision measurement, setup and calibration, and material handling. Additionally, they should have a keen eye for detail, a strong understanding of safety protocols, and the ability to troubleshoot and resolve technical issues.

What are the typical job responsibilities of an Incising Machine Operator?

Incising Machine Operators are responsible for setting up and calibrating incising machines, loading and positioning materials, operating machines to create precise incisions, monitoring and maintaining incision quality, performing regular maintenance and troubleshooting, adhering to safety protocols, and collaborating with production teams.

What industries employ Incising Machine Operators?

Incising Machine Operators are employed in various industries that require precision cutting and incision services, including manufacturing, packaging, and electronics.

What is the average salary range for Incising Machine Operators?

The average salary range for Incising Machine Operators can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for Incising Machine Operators in the United States is around $50,000 per year.

What are the career advancement opportunities for Incising Machine Operators?

Incising Machine Operators can advance their careers by gaining experience and developing specialized skills. They can move into supervisory roles, become trainers, or specialize in specific areas such as quality control or machine maintenance.

What are the educational requirements to become an Incising Machine Operator?

While there are no specific educational requirements to become an Incising Machine Operator, many employers prefer candidates with a high school diploma or equivalent. Some employers may also prefer candidates with experience in manufacturing or a related field.

Is experience necessary to become an Incising Machine Operator?

Experience is not always necessary to become an Incising Machine Operator, but it can be beneficial. Many employers prefer candidates with previous experience operating incising machines or working in a manufacturing environment.

What are the safety precautions that Incising Machine Operators should follow?

Incising Machine Operators should follow all established safety protocols and guidelines, including wearing appropriate personal protective equipment, being aware of moving machinery, and following proper lockout/tagout procedures.