Are you a seasoned Industrial Technician seeking a new career path? Discover our professionally built Industrial Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

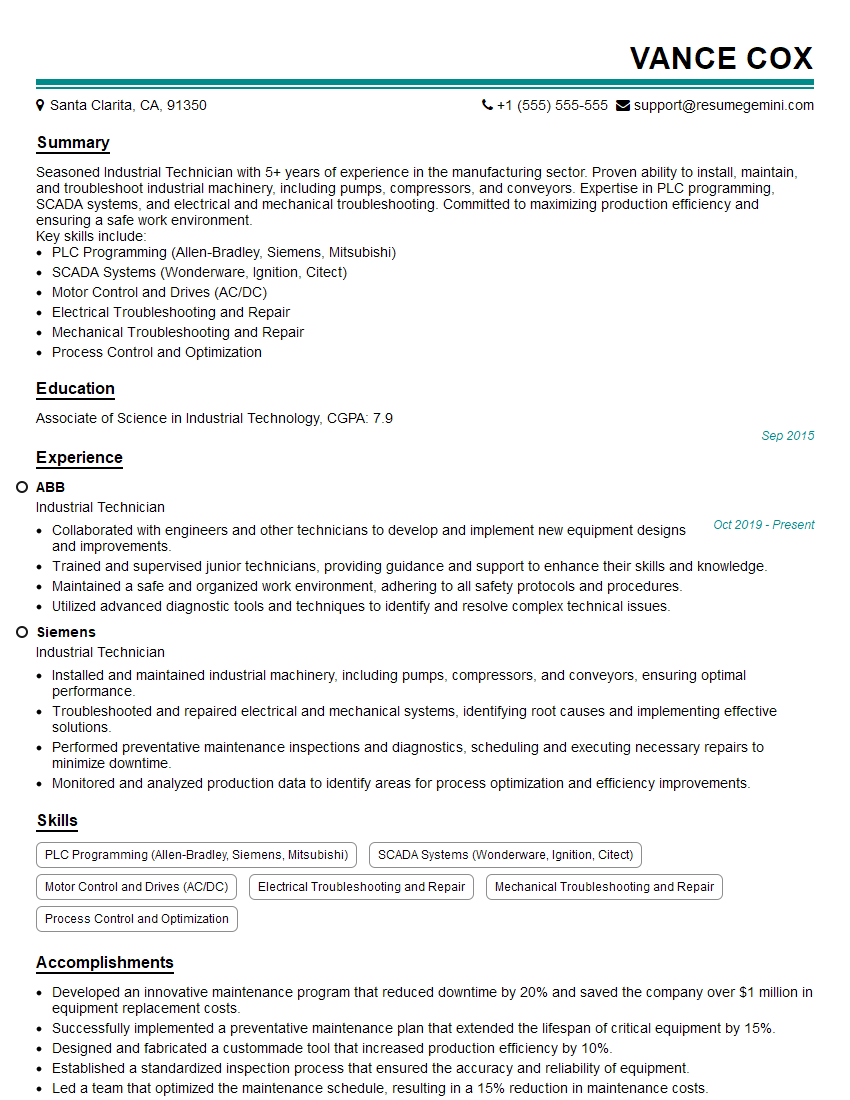

Vance Cox

Industrial Technician

Summary

Seasoned Industrial Technician with 5+ years of experience in the manufacturing sector. Proven ability to install, maintain, and troubleshoot industrial machinery, including pumps, compressors, and conveyors. Expertise in PLC programming, SCADA systems, and electrical and mechanical troubleshooting. Committed to maximizing production efficiency and ensuring a safe work environment.

Key skills include:

- PLC Programming (Allen-Bradley, Siemens, Mitsubishi)

- SCADA Systems (Wonderware, Ignition, Citect)

- Motor Control and Drives (AC/DC)

- Electrical Troubleshooting and Repair

- Mechanical Troubleshooting and Repair

- Process Control and Optimization

Education

Associate of Science in Industrial Technology

September 2015

Skills

- PLC Programming (Allen-Bradley, Siemens, Mitsubishi)

- SCADA Systems (Wonderware, Ignition, Citect)

- Motor Control and Drives (AC/DC)

- Electrical Troubleshooting and Repair

- Mechanical Troubleshooting and Repair

- Process Control and Optimization

Work Experience

Industrial Technician

- Collaborated with engineers and other technicians to develop and implement new equipment designs and improvements.

- Trained and supervised junior technicians, providing guidance and support to enhance their skills and knowledge.

- Maintained a safe and organized work environment, adhering to all safety protocols and procedures.

- Utilized advanced diagnostic tools and techniques to identify and resolve complex technical issues.

Industrial Technician

- Installed and maintained industrial machinery, including pumps, compressors, and conveyors, ensuring optimal performance.

- Troubleshooted and repaired electrical and mechanical systems, identifying root causes and implementing effective solutions.

- Performed preventative maintenance inspections and diagnostics, scheduling and executing necessary repairs to minimize downtime.

- Monitored and analyzed production data to identify areas for process optimization and efficiency improvements.

Accomplishments

- Developed an innovative maintenance program that reduced downtime by 20% and saved the company over $1 million in equipment replacement costs.

- Successfully implemented a preventative maintenance plan that extended the lifespan of critical equipment by 15%.

- Designed and fabricated a custommade tool that increased production efficiency by 10%.

- Established a standardized inspection process that ensured the accuracy and reliability of equipment.

- Led a team that optimized the maintenance schedule, resulting in a 15% reduction in maintenance costs.

Awards

- Received the Industrial Technician of the Year Award from the National Institute of Industrial Engineers (NIIE).

- Recognized for outstanding performance in troubleshooting and repairing complex industrial machinery.

- Received the Safety Award for consistently adhering to safety protocols and preventing workplace accidents.

- Honored for developing a training program that improved the technical skills of fellow technicians.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Industrial Automation Professional (CIAP)

- Certified Automation Professional (CAP)

- Certified PLC Programmer (PLCP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Technician

- Highlight your technical skills and experience in PLC programming, SCADA systems, and industrial machinery repair.

- Quantify your accomplishments with specific metrics, such as the reduction in downtime or the increase in production efficiency.

- Showcase your ability to work independently and as part of a team.

- Emphasize your commitment to safety and your knowledge of industry best practices.

Essential Experience Highlights for a Strong Industrial Technician Resume

- Installed and maintained industrial machinery, including pumps, compressors, and conveyors, ensuring optimal performance.

- Troubleshooted and repaired electrical and mechanical systems, identifying root causes and implementing effective solutions.

- Performed preventative maintenance inspections and diagnostics, scheduling and executing necessary repairs to minimize downtime.

- Monitored and analyzed production data to identify areas for process optimization and efficiency improvements.

- Collaborated with engineers and other technicians to develop and implement new equipment designs and improvements.

- Trained and supervised junior technicians, providing guidance and support to enhance their skills and knowledge.

- Maintained a safe and organized work environment, adhering to all safety protocols and procedures.

- Utilized advanced diagnostic tools and techniques to identify and resolve complex technical issues.

Frequently Asked Questions (FAQ’s) For Industrial Technician

What is the role of an Industrial Technician?

An Industrial Technician is responsible for installing, maintaining, and repairing industrial machinery and equipment. They troubleshoot electrical and mechanical problems, perform preventative maintenance, and work to ensure that production processes run smoothly and efficiently.

What skills are required to be an Industrial Technician?

Industrial Technicians typically have a strong understanding of electrical and mechanical systems, PLC programming, and SCADA systems. They should also be able to read and interpret blueprints, work independently, and have a strong commitment to safety.

What is the job outlook for Industrial Technicians?

The job outlook for Industrial Technicians is expected to be positive in the coming years. The increasing use of automation and robotics in manufacturing is creating a growing demand for skilled technicians who can install, maintain, and repair these systems.

What are the earning prospects for Industrial Technicians?

The earning potential for Industrial Technicians can vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Industrial Machinery Mechanics was $49,590 in May 2021.

What is the difference between an Industrial Technician and a Maintenance Technician?

Industrial Technicians typically have a more specialized skillset than Maintenance Technicians. They are responsible for maintaining and repairing specific types of industrial machinery, such as pumps, compressors, and conveyors. Maintenance Technicians, on the other hand, are responsible for maintaining a wider range of equipment, including buildings, vehicles, and grounds.

What are the career advancement opportunities for Industrial Technicians?

With experience, Industrial Technicians can advance to positions such as Maintenance Supervisor, Engineering Technician, or Project Manager. They may also choose to specialize in a particular area, such as PLC programming or robotics.