Are you a seasoned Industrial Welder seeking a new career path? Discover our professionally built Industrial Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

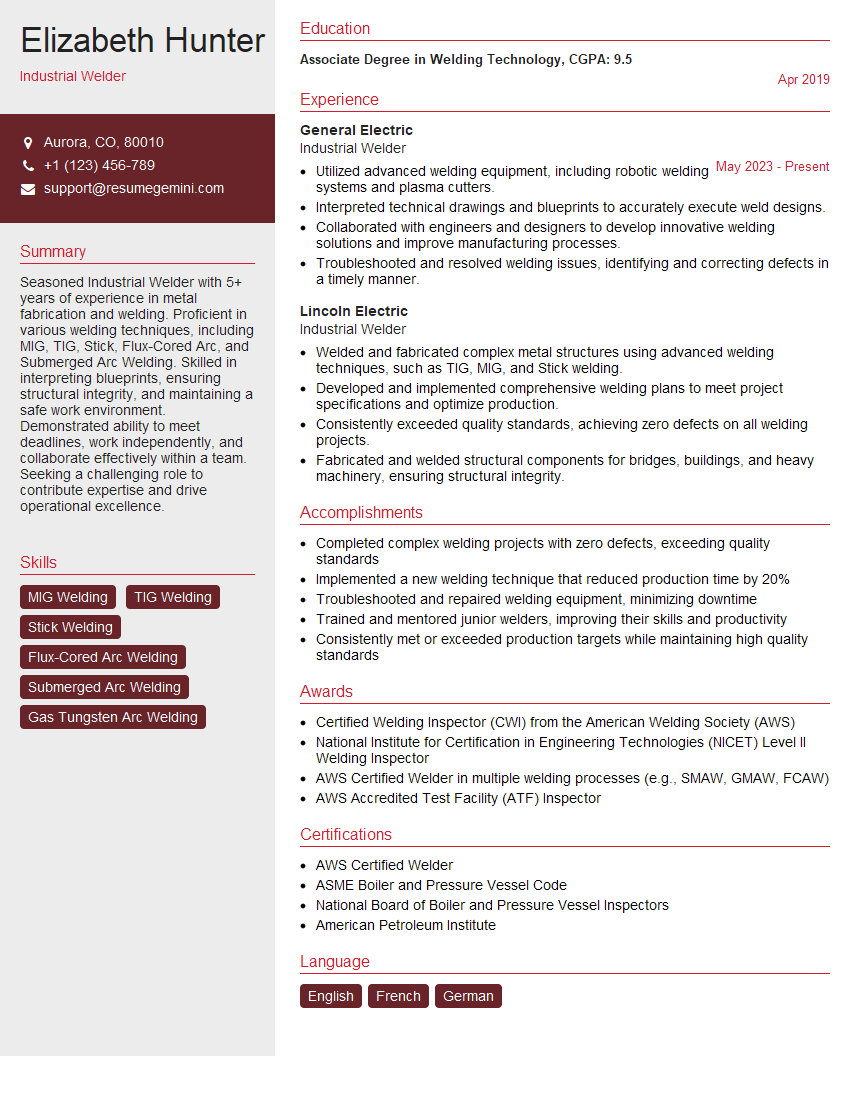

Elizabeth Hunter

Industrial Welder

Summary

Seasoned Industrial Welder with 5+ years of experience in metal fabrication and welding. Proficient in various welding techniques, including MIG, TIG, Stick, Flux-Cored Arc, and Submerged Arc Welding. Skilled in interpreting blueprints, ensuring structural integrity, and maintaining a safe work environment. Demonstrated ability to meet deadlines, work independently, and collaborate effectively within a team. Seeking a challenging role to contribute expertise and drive operational excellence.

Education

Associate Degree in Welding Technology

April 2019

Skills

- MIG Welding

- TIG Welding

- Stick Welding

- Flux-Cored Arc Welding

- Submerged Arc Welding

- Gas Tungsten Arc Welding

Work Experience

Industrial Welder

- Utilized advanced welding equipment, including robotic welding systems and plasma cutters.

- Interpreted technical drawings and blueprints to accurately execute weld designs.

- Collaborated with engineers and designers to develop innovative welding solutions and improve manufacturing processes.

- Troubleshooted and resolved welding issues, identifying and correcting defects in a timely manner.

Industrial Welder

- Welded and fabricated complex metal structures using advanced welding techniques, such as TIG, MIG, and Stick welding.

- Developed and implemented comprehensive welding plans to meet project specifications and optimize production.

- Consistently exceeded quality standards, achieving zero defects on all welding projects.

- Fabricated and welded structural components for bridges, buildings, and heavy machinery, ensuring structural integrity.

Accomplishments

- Completed complex welding projects with zero defects, exceeding quality standards

- Implemented a new welding technique that reduced production time by 20%

- Troubleshooted and repaired welding equipment, minimizing downtime

- Trained and mentored junior welders, improving their skills and productivity

- Consistently met or exceeded production targets while maintaining high quality standards

Awards

- Certified Welding Inspector (CWI) from the American Welding Society (AWS)

- National Institute for Certification in Engineering Technologies (NICET) Level II Welding Inspector

- AWS Certified Welder in multiple welding processes (e.g., SMAW, GMAW, FCAW)

- AWS Accredited Test Facility (ATF) Inspector

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- National Board of Boiler and Pressure Vessel Inspectors

- American Petroleum Institute

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Welder

- Highlight your proficiency in various welding techniques and the ability to select appropriate methods based on project requirements.

- Quantify your accomplishments whenever possible. For example, instead of saying ‘welded metal components,’ you could say ‘welded 500+ metal components within specified tolerances.’

- Showcase your understanding of welding codes and standards, and emphasize your commitment to quality assurance.

- Demonstrate your attention to detail and ability to work independently. Mention your experience in inspecting welds and identifying any potential defects.

Essential Experience Highlights for a Strong Industrial Welder Resume

- Interpret blueprints and welding specifications to determine appropriate welding techniques and materials.

- Operate and maintain welding equipment, including MIG, TIG, Stick, Flux-Cored Arc, and Submerged Arc Welding machines.

- Weld metal components according to specifications, ensuring structural integrity and adherence to industry standards.

- Inspect welds visually and using non-destructive testing methods to ensure quality and compliance.

- Contribute to continuous improvement initiatives by identifying areas for process optimization and efficiency enhancements.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

- Collaborate with engineers, fabricators, and other team members to achieve project goals.

Frequently Asked Questions (FAQ’s) For Industrial Welder

What are the primary responsibilities of an Industrial Welder?

Industrial Welders are responsible for interpreting blueprints, operating welding equipment, performing welds according to specifications, inspecting welds for quality, and adhering to safety protocols.

What are the different types of welding techniques used in industrial settings?

Common welding techniques include MIG, TIG, Stick, Flux-Cored Arc, and Submerged Arc Welding, each with its own advantages and applications.

What are the essential skills for a successful Industrial Welder?

Industrial Welders require proficiency in welding techniques, blueprint interpretation, quality control, safety practices, and teamwork.

What are the educational requirements for becoming an Industrial Welder?

While formal education is not always required, many Industrial Welders hold an Associate Degree in Welding Technology or a????

What industries employ Industrial Welders?

Industrial Welders are employed in various industries, including manufacturing, construction, shipbuilding, and automotive.

What are the career advancement opportunities for Industrial Welders?

With experience and additional training, Industrial Welders can advance to supervisory roles, welding inspectors, or specialized welding positions.

What safety precautions should Industrial Welders take?

Industrial Welders must wear appropriate protective gear, ensure proper ventilation, and follow established safety protocols to minimize risks associated with welding.

How do I prepare for an interview for an Industrial Welder position?

Research the company, practice answering common interview questions, and demonstrate your knowledge of welding techniques, safety procedures, and industry standards.