Are you a seasoned Ingot Caster seeking a new career path? Discover our professionally built Ingot Caster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

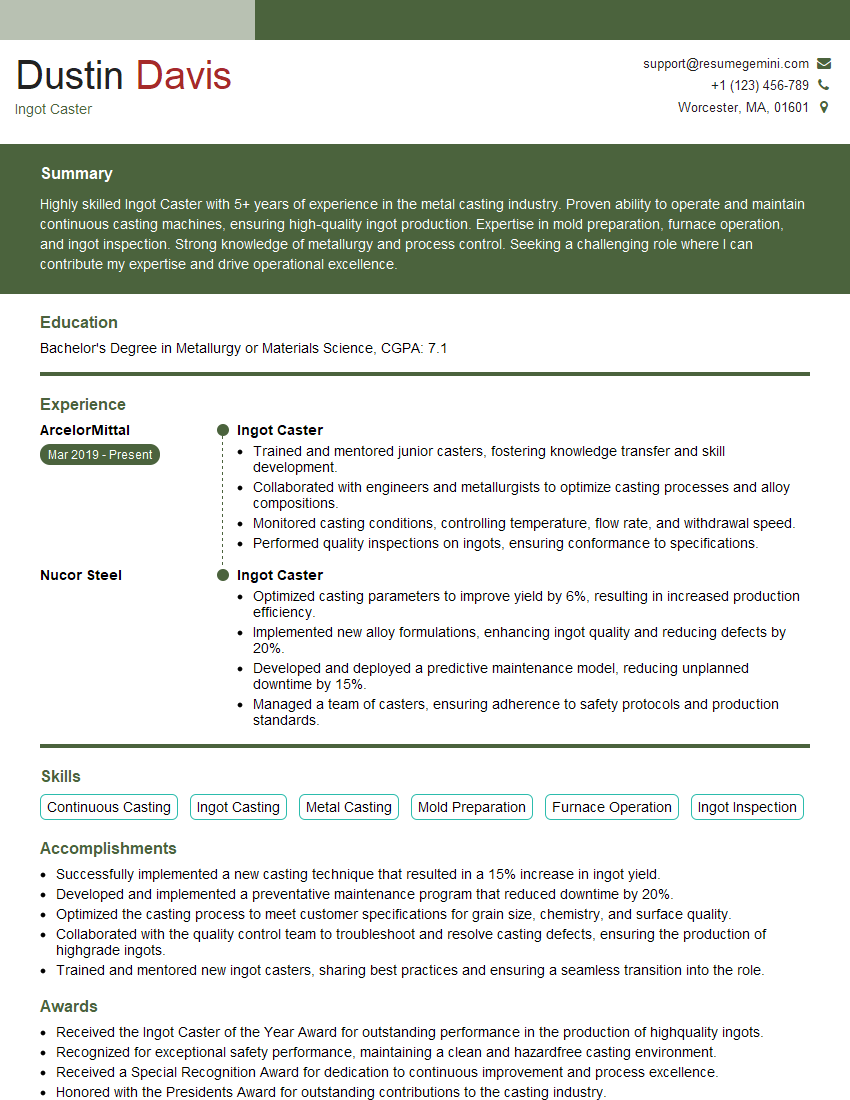

Dustin Davis

Ingot Caster

Summary

Highly skilled Ingot Caster with 5+ years of experience in the metal casting industry. Proven ability to operate and maintain continuous casting machines, ensuring high-quality ingot production. Expertise in mold preparation, furnace operation, and ingot inspection. Strong knowledge of metallurgy and process control. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor’s Degree in Metallurgy or Materials Science

February 2015

Skills

- Continuous Casting

- Ingot Casting

- Metal Casting

- Mold Preparation

- Furnace Operation

- Ingot Inspection

Work Experience

Ingot Caster

- Trained and mentored junior casters, fostering knowledge transfer and skill development.

- Collaborated with engineers and metallurgists to optimize casting processes and alloy compositions.

- Monitored casting conditions, controlling temperature, flow rate, and withdrawal speed.

- Performed quality inspections on ingots, ensuring conformance to specifications.

Ingot Caster

- Optimized casting parameters to improve yield by 6%, resulting in increased production efficiency.

- Implemented new alloy formulations, enhancing ingot quality and reducing defects by 20%.

- Developed and deployed a predictive maintenance model, reducing unplanned downtime by 15%.

- Managed a team of casters, ensuring adherence to safety protocols and production standards.

Accomplishments

- Successfully implemented a new casting technique that resulted in a 15% increase in ingot yield.

- Developed and implemented a preventative maintenance program that reduced downtime by 20%.

- Optimized the casting process to meet customer specifications for grain size, chemistry, and surface quality.

- Collaborated with the quality control team to troubleshoot and resolve casting defects, ensuring the production of highgrade ingots.

- Trained and mentored new ingot casters, sharing best practices and ensuring a seamless transition into the role.

Awards

- Received the Ingot Caster of the Year Award for outstanding performance in the production of highquality ingots.

- Recognized for exceptional safety performance, maintaining a clean and hazardfree casting environment.

- Received a Special Recognition Award for dedication to continuous improvement and process excellence.

- Honored with the Presidents Award for outstanding contributions to the casting industry.

Certificates

- Certified Ingot Caster

- Metallurgy Technician Certification

- Safety Compliance Certification

- Continuous Casting Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ingot Caster

- Highlight your experience in operating and maintaining continuous casting machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Demonstrate your knowledge of metallurgy and process control by discussing how you have applied them in your role.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Ingot Caster Resume

- Operate and maintain continuous casting machines, including mold preparation and furnace operation.

- Control casting parameters to ensure the production of high-quality ingots.

- Inspect ingots for defects and ensure compliance with quality standards.

- Monitor and adjust process variables to optimize production efficiency and minimize downtime.

- Troubleshoot and resolve casting issues promptly to minimize production losses.

- Maintain a clean and safe work environment in accordance with industry regulations.

Frequently Asked Questions (FAQ’s) For Ingot Caster

What is the role of an Ingot Caster?

An Ingot Caster is responsible for operating and maintaining continuous casting machines to produce high-quality ingots used in various metalworking applications.

What skills are required to be an Ingot Caster?

Ingot Casters typically require a combination of technical skills, including knowledge of metallurgy, process control, and machine operation, as well as strong problem-solving and analytical abilities.

What is the work environment of an Ingot Caster?

Ingot Casters typically work in industrial settings, such as steel mills or foundries. The work can be physically demanding and may involve exposure to heat, noise, and fumes.

What are the career prospects for an Ingot Caster?

With experience and additional training, Ingot Casters can advance to supervisory or management roles within the metal casting industry.

What is the salary range for an Ingot Caster?

The salary range for Ingot Casters can vary depending on experience, location, and industry. According to Indeed, the average salary for an Ingot Caster in the United States is around $65,000 per year.

What are the challenges faced by Ingot Casters?

Ingot Casters may face challenges related to maintaining high production standards, ensuring product quality, and working in a demanding industrial environment.

What are the safety precautions that Ingot Casters must follow?

Ingot Casters must adhere to strict safety protocols to minimize the risk of accidents, including wearing appropriate protective gear and following established operating procedures.