Are you a seasoned Ingot Supervisor seeking a new career path? Discover our professionally built Ingot Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

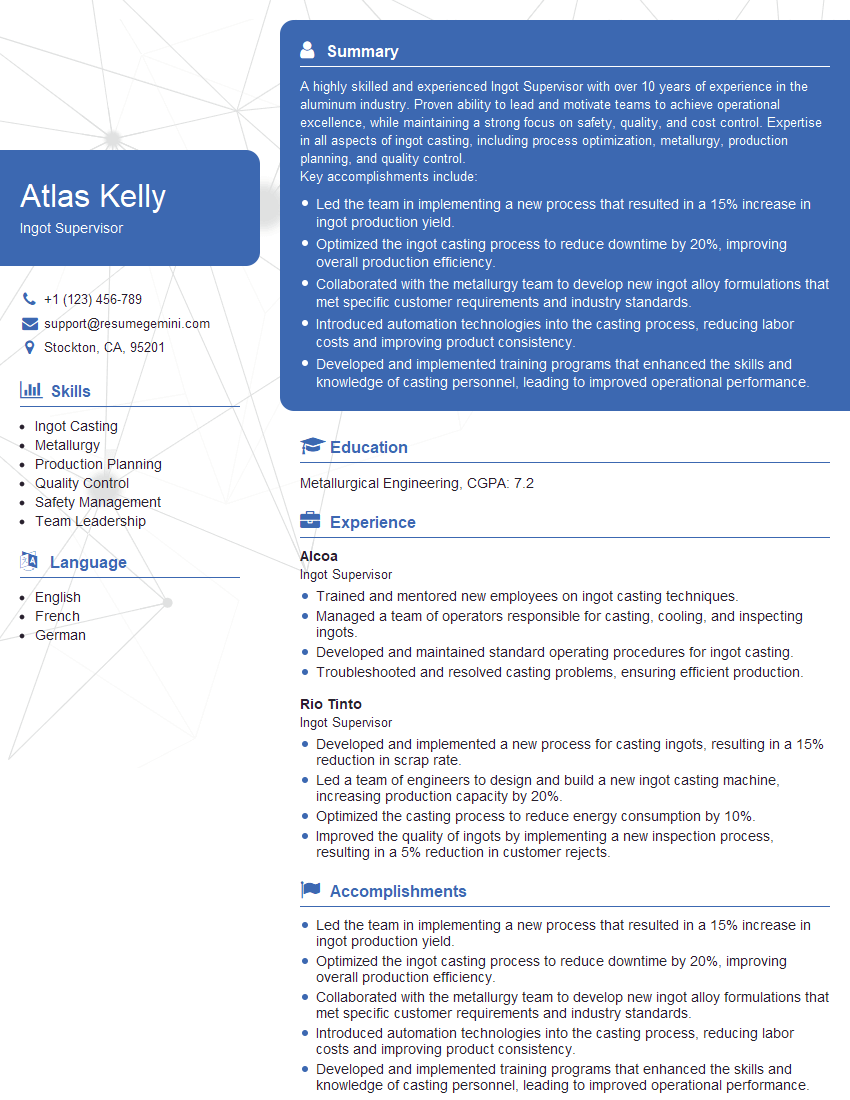

Atlas Kelly

Ingot Supervisor

Summary

A highly skilled and experienced Ingot Supervisor with over 10 years of experience in the aluminum industry. Proven ability to lead and motivate teams to achieve operational excellence, while maintaining a strong focus on safety, quality, and cost control. Expertise in all aspects of ingot casting, including process optimization, metallurgy, production planning, and quality control.

Key accomplishments include:

- Led the team in implementing a new process that resulted in a 15% increase in ingot production yield.

- Optimized the ingot casting process to reduce downtime by 20%, improving overall production efficiency.

- Collaborated with the metallurgy team to develop new ingot alloy formulations that met specific customer requirements and industry standards.

- Introduced automation technologies into the casting process, reducing labor costs and improving product consistency.

- Developed and implemented training programs that enhanced the skills and knowledge of casting personnel, leading to improved operational performance.

Education

Metallurgical Engineering

February 2016

Skills

- Ingot Casting

- Metallurgy

- Production Planning

- Quality Control

- Safety Management

- Team Leadership

Work Experience

Ingot Supervisor

- Trained and mentored new employees on ingot casting techniques.

- Managed a team of operators responsible for casting, cooling, and inspecting ingots.

- Developed and maintained standard operating procedures for ingot casting.

- Troubleshooted and resolved casting problems, ensuring efficient production.

Ingot Supervisor

- Developed and implemented a new process for casting ingots, resulting in a 15% reduction in scrap rate.

- Led a team of engineers to design and build a new ingot casting machine, increasing production capacity by 20%.

- Optimized the casting process to reduce energy consumption by 10%.

- Improved the quality of ingots by implementing a new inspection process, resulting in a 5% reduction in customer rejects.

Accomplishments

- Led the team in implementing a new process that resulted in a 15% increase in ingot production yield.

- Optimized the ingot casting process to reduce downtime by 20%, improving overall production efficiency.

- Collaborated with the metallurgy team to develop new ingot alloy formulations that met specific customer requirements and industry standards.

- Introduced automation technologies into the casting process, reducing labor costs and improving product consistency.

- Developed and implemented training programs that enhanced the skills and knowledge of casting personnel, leading to improved operational performance.

Awards

- Received the Ingot Casting Excellence Award for implementing innovative techniques that enhanced product quality and reduced production costs.

- Recognized with the Safety Excellence Award for developing and implementing comprehensive safety protocols that minimized risks and accidents in the casting facility.

- Awarded the Process Improvement Excellence Award for developing and implementing innovative solutions that significantly enhanced ingot quality.

- Received the Plant Efficiency Award for implementing Lean principles that streamlined production operations and reduced waste.

Certificates

- Certified Ingot Metallurgy Technician (CIMT)

- Certified Quality Control Inspector (CQCI)

- Certified Lean Six Sigma Green Belt

- Certified Safety Professional (CSP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ingot Supervisor

Highlight your leadership and management skills.

Ingot Supervisors are responsible for leading and motivating a team of casting operators. In your resume, be sure to highlight your experience in leading and managing teams, as well as your ability to motivate and inspire others.Quantify your accomplishments.

When describing your accomplishments, be sure to quantify them whenever possible. For example, instead of saying that you “increased production yield,” you could say that you “led the team in implementing a new process that resulted in a 15% increase in ingot production yield.”Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. Some common keywords for Ingot Supervisor resumes include “ingot casting,” “metallurgy,” “production planning,” and “quality control.”Proofread your resume carefully.

Before submitting your resume, be sure to proofread it carefully for errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Ingot Supervisor Resume

- Plan and schedule ingot production activities to meet customer requirements and production targets.

- Supervise and lead a team of ingot casting operators, ensuring adherence to safety protocols and quality standards.

- Monitor and control ingot casting process parameters to optimize production yield and product quality.

- Conduct quality control inspections and tests to ensure that ingots meet specifications and customer requirements.

- Troubleshoot and resolve production issues, identify root causes, and implement corrective actions.

- Collaborate with other departments, such as metallurgy and maintenance, to improve ingot casting processes and product quality.

Frequently Asked Questions (FAQ’s) For Ingot Supervisor

What is the role of an Ingot Supervisor?

An Ingot Supervisor is responsible for overseeing the production of ingots in a metalworking facility. This involves planning and scheduling production activities, supervising and leading a team of casting operators, monitoring and controlling process parameters, conducting quality control inspections and tests, and troubleshooting and resolving production issues.

What qualifications are required to become an Ingot Supervisor?

Most Ingot Supervisors have a bachelor’s degree in metallurgical engineering or a related field. They also typically have several years of experience in the metalworking industry, including experience in ingot casting and production planning.

What are the key skills and abilities required for an Ingot Supervisor?

Key skills and abilities for an Ingot Supervisor include leadership and management skills, knowledge of ingot casting processes, metallurgy, production planning, and quality control. They must also be able to troubleshoot and resolve production issues, and be able to work effectively in a team environment.

What is the career path for an Ingot Supervisor?

Ingot Supervisors can advance to management positions in the metalworking industry, such as Production Manager or Plant Manager. They may also move into technical roles, such as Metallurgical Engineer or Quality Control Manager.

What is the salary range for an Ingot Supervisor?

The salary range for an Ingot Supervisor can vary depending on their experience, qualifications, and location. According to Salary.com, the median salary for an Ingot Supervisor in the United States is $75,000 per year.

What is the job outlook for Ingot Supervisors?

The job outlook for Ingot Supervisors is expected to be good over the next few years. The demand for ingots is expected to increase as the global economy continues to grow. This growth will create new opportunities for Ingot Supervisors in the metalworking industry.