Are you a seasoned Injection Machine Operator seeking a new career path? Discover our professionally built Injection Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

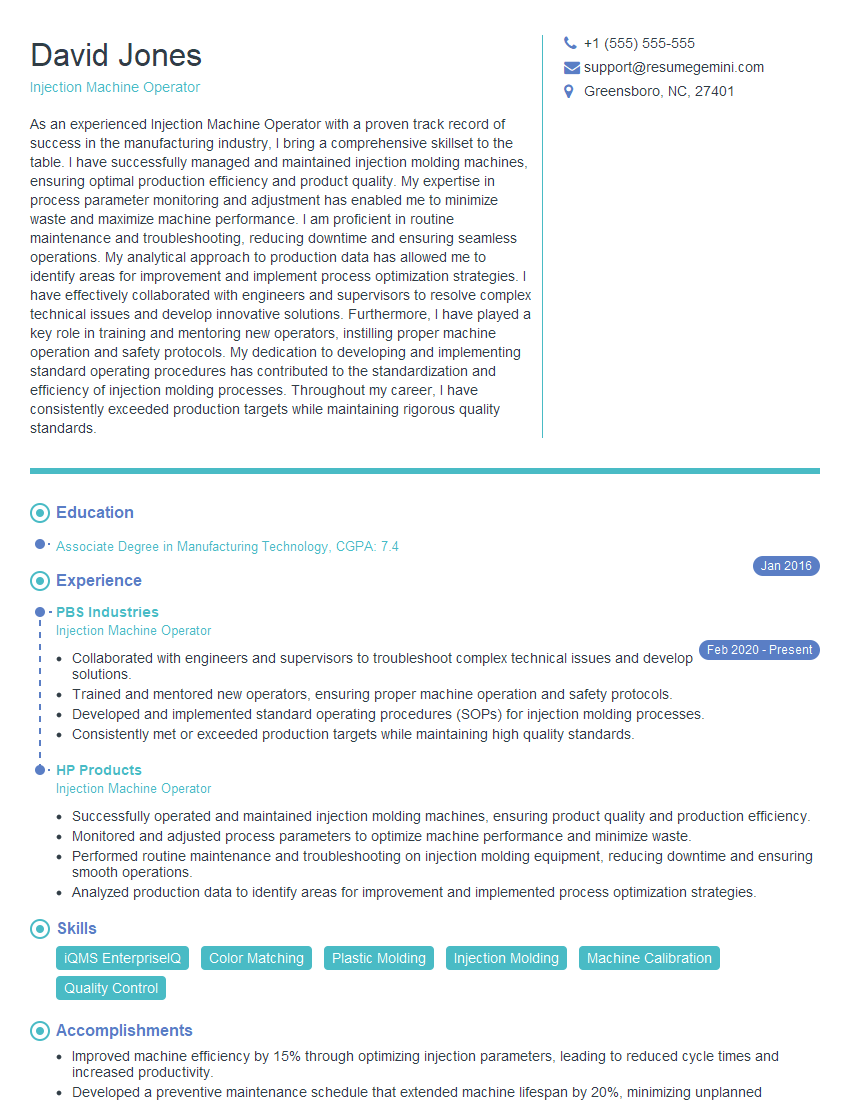

David Jones

Injection Machine Operator

Summary

As an experienced Injection Machine Operator with a proven track record of success in the manufacturing industry, I bring a comprehensive skillset to the table. I have successfully managed and maintained injection molding machines, ensuring optimal production efficiency and product quality. My expertise in process parameter monitoring and adjustment has enabled me to minimize waste and maximize machine performance. I am proficient in routine maintenance and troubleshooting, reducing downtime and ensuring seamless operations. My analytical approach to production data has allowed me to identify areas for improvement and implement process optimization strategies. I have effectively collaborated with engineers and supervisors to resolve complex technical issues and develop innovative solutions. Furthermore, I have played a key role in training and mentoring new operators, instilling proper machine operation and safety protocols. My dedication to developing and implementing standard operating procedures has contributed to the standardization and efficiency of injection molding processes. Throughout my career, I have consistently exceeded production targets while maintaining rigorous quality standards.

Education

Associate Degree in Manufacturing Technology

January 2016

Skills

- iQMS EnterpriseIQ

- Color Matching

- Plastic Molding

- Injection Molding

- Machine Calibration

- Quality Control

Work Experience

Injection Machine Operator

- Collaborated with engineers and supervisors to troubleshoot complex technical issues and develop solutions.

- Trained and mentored new operators, ensuring proper machine operation and safety protocols.

- Developed and implemented standard operating procedures (SOPs) for injection molding processes.

- Consistently met or exceeded production targets while maintaining high quality standards.

Injection Machine Operator

- Successfully operated and maintained injection molding machines, ensuring product quality and production efficiency.

- Monitored and adjusted process parameters to optimize machine performance and minimize waste.

- Performed routine maintenance and troubleshooting on injection molding equipment, reducing downtime and ensuring smooth operations.

- Analyzed production data to identify areas for improvement and implemented process optimization strategies.

Accomplishments

- Improved machine efficiency by 15% through optimizing injection parameters, leading to reduced cycle times and increased productivity.

- Developed a preventive maintenance schedule that extended machine lifespan by 20%, minimizing unplanned disruptions and maintenance costs.

- Successfully implemented a new quality control protocol, reducing product defects by 30% and improving customer satisfaction.

- Developed a detailed training program for new operators, significantly reducing onboarding time and ensuring consistent performance.

- Successfully led a team to implement a lean manufacturing initiative, resulting in a 25% reduction in production time and improved resource allocation.

Awards

- Received the Injection Molding Excellence Award for consistently exceeding production targets while maintaining highquality standards.

- Recognized for Operational Excellence for implementing innovative solutions that enhanced machine performance and reduced downtime.

- Won the Safety Superstar Award for maintaining an impeccable safety record and promoting safe work practices on the production floor.

- Received the Training and Development Award for mentoring junior operators and sharing best practices to enhance their skills.

Certificates

- Certified Injection Machine Operator

- ASME B15.1 Safety Standard for Mechanical Power Transmission Equipment

- ISO 9001:2015 Quality Management System

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Machine Operator

- Highlight your experience and skills in operating and maintaining injection molding machines, including your ability to optimize machine performance and minimize waste.

- Showcase your knowledge of injection molding processes and your ability to analyze production data to identify areas for improvement.

- Emphasize your ability to troubleshoot and resolve complex technical issues, as well as your experience in training and mentoring new operators.

- Demonstrate your commitment to quality and your ability to consistently meet or exceed production targets while maintaining high quality standards.

Essential Experience Highlights for a Strong Injection Machine Operator Resume

- Operate and maintain injection molding machines to produce high-quality plastic products

- Monitor and adjust process parameters, such as temperature, pressure, and cycle time, to optimize machine performance and minimize waste

- Perform routine maintenance and troubleshooting on injection molding equipment, including cleaning, lubrication, and minor repairs

- Analyze production data to identify areas for improvement and implement process optimization strategies

- Collaborate with engineers and supervisors to troubleshoot complex technical issues and develop solutions

- Train and mentor new operators on proper machine operation and safety protocols

- Develop and implement standard operating procedures (SOPs) for injection molding processes

Frequently Asked Questions (FAQ’s) For Injection Machine Operator

What are the key responsibilities of an Injection Machine Operator?

The key responsibilities of an Injection Machine Operator include operating and maintaining injection molding machines, monitoring and adjusting process parameters, performing routine maintenance and troubleshooting, analyzing production data, collaborating with engineers and supervisors, training and mentoring new operators, and developing and implementing standard operating procedures.

What are the educational requirements for an Injection Machine Operator?

While formal educational requirements may vary depending on the specific industry and employer, many Injection Machine Operators hold an Associate Degree in Manufacturing Technology or a related field.

What are the essential skills for an Injection Machine Operator?

Essential skills for an Injection Machine Operator include proficiency in operating and maintaining injection molding machines, knowledge of injection molding processes, ability to analyze production data, problem-solving skills, and attention to detail.

What is the job outlook for Injection Machine Operators?

The job outlook for Injection Machine Operators is expected to be favorable in the coming years due to the increasing demand for plastic products across various industries.

What is the average salary for an Injection Machine Operator?

The average salary for an Injection Machine Operator can vary depending on experience, location, and industry, but typically falls within a range of $30,000 to $50,000 per year.

What are the career advancement opportunities for Injection Machine Operators?

With experience and additional training, Injection Machine Operators can advance to positions such as Production Supervisor, Quality Control Inspector, or Manufacturing Engineer.