Are you a seasoned Injection Mold Technician seeking a new career path? Discover our professionally built Injection Mold Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

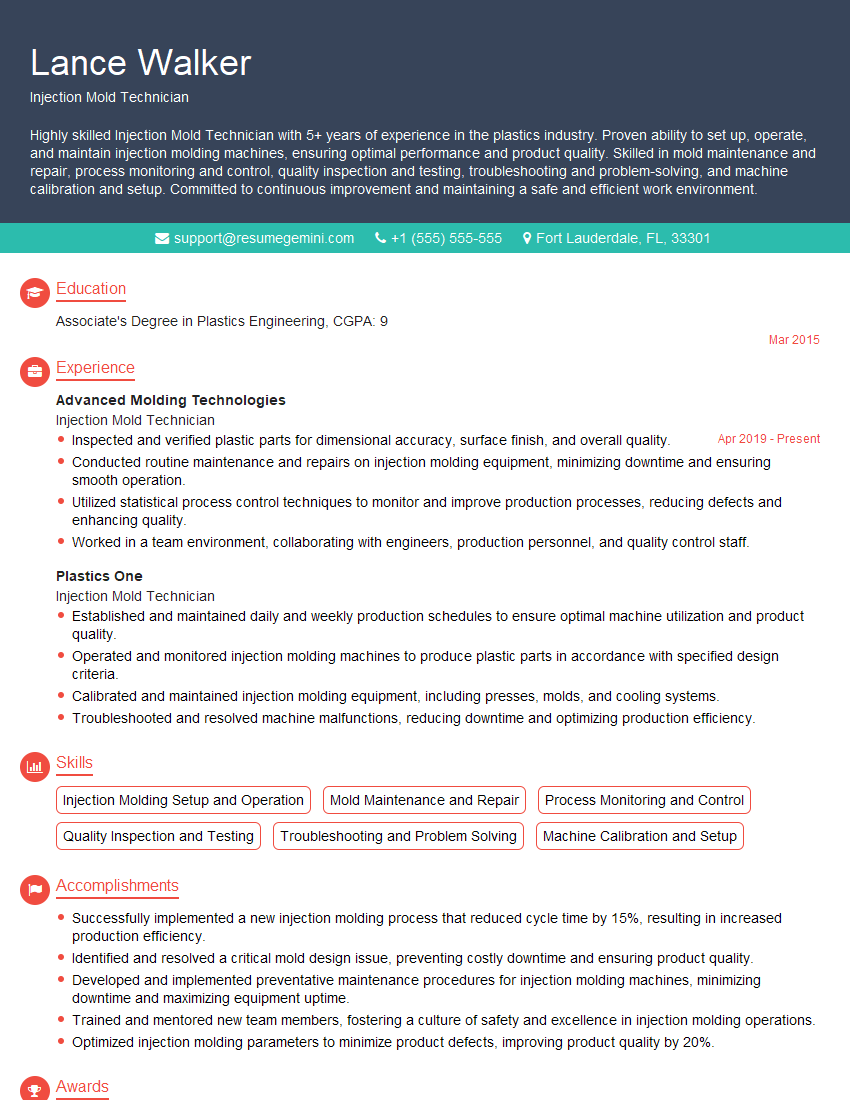

Lance Walker

Injection Mold Technician

Summary

Highly skilled Injection Mold Technician with 5+ years of experience in the plastics industry. Proven ability to set up, operate, and maintain injection molding machines, ensuring optimal performance and product quality. Skilled in mold maintenance and repair, process monitoring and control, quality inspection and testing, troubleshooting and problem-solving, and machine calibration and setup. Committed to continuous improvement and maintaining a safe and efficient work environment.

Education

Associate’s Degree in Plastics Engineering

March 2015

Skills

- Injection Molding Setup and Operation

- Mold Maintenance and Repair

- Process Monitoring and Control

- Quality Inspection and Testing

- Troubleshooting and Problem Solving

- Machine Calibration and Setup

Work Experience

Injection Mold Technician

- Inspected and verified plastic parts for dimensional accuracy, surface finish, and overall quality.

- Conducted routine maintenance and repairs on injection molding equipment, minimizing downtime and ensuring smooth operation.

- Utilized statistical process control techniques to monitor and improve production processes, reducing defects and enhancing quality.

- Worked in a team environment, collaborating with engineers, production personnel, and quality control staff.

Injection Mold Technician

- Established and maintained daily and weekly production schedules to ensure optimal machine utilization and product quality.

- Operated and monitored injection molding machines to produce plastic parts in accordance with specified design criteria.

- Calibrated and maintained injection molding equipment, including presses, molds, and cooling systems.

- Troubleshooted and resolved machine malfunctions, reducing downtime and optimizing production efficiency.

Accomplishments

- Successfully implemented a new injection molding process that reduced cycle time by 15%, resulting in increased production efficiency.

- Identified and resolved a critical mold design issue, preventing costly downtime and ensuring product quality.

- Developed and implemented preventative maintenance procedures for injection molding machines, minimizing downtime and maximizing equipment uptime.

- Trained and mentored new team members, fostering a culture of safety and excellence in injection molding operations.

- Optimized injection molding parameters to minimize product defects, improving product quality by 20%.

Awards

- Received the Employee of the Month award for exceptional performance and dedication in plastic injection molding processes.

- Recognized for outstanding contributions to the Injection Molding Department, receiving the Team Excellence Award.

- Won the Safety Award for adhering to all safety protocols and contributing to a safe work environment.

- Received the Customer Service Excellence Award for consistently exceeding customer expectations and providing exceptional support.

Certificates

- Certified Mold Technician (CMT)

- Certified Plastics Technician (CPT)

- ISO 9001 Quality Management System

- Lean Manufacturing Principles

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Mold Technician

- Highlight your skills and experience in injection molding setup and operation, mold maintenance and repair, process monitoring and control, and quality inspection and testing.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Injection Mold Technician Resume

- Setup and operate injection molding machines to produce plastic parts according to specifications

- Perform routine maintenance and repairs on molds, including cleaning, lubrication, and replacement of worn parts

- Monitor and control injection molding processes to ensure quality and efficiency

- Conduct quality inspections and testing to ensure that parts meet specifications

- Troubleshoot and solve problems with injection molding machines and molds

- Calibrate and setup injection molding machines to optimize performance

Frequently Asked Questions (FAQ’s) For Injection Mold Technician

What is the role of an Injection Mold Technician?

The role of an Injection Mold Technician is to set up, operate, and maintain injection molding machines, ensuring optimal performance and product quality.

What are the key skills required for an Injection Mold Technician?

The key skills required for an Injection Mold Technician include injection molding setup and operation, mold maintenance and repair, process monitoring and control, quality inspection and testing, troubleshooting and problem-solving, and machine calibration and setup.

What are the typical responsibilities of an Injection Mold Technician?

The typical responsibilities of an Injection Mold Technician include setting up and operating injection molding machines, performing routine maintenance and repairs on molds, monitoring and controlling injection molding processes, conducting quality inspections and testing, troubleshooting and solving problems with injection molding machines and molds, and calibrating and setting up injection molding machines to optimize performance.

What are the career prospects for an Injection Mold Technician?

The career prospects for an Injection Mold Technician are good, with a growing demand for skilled technicians in the plastics industry.

How can I become an Injection Mold Technician?

You can become an Injection Mold Technician by completing an associate’s degree in plastics engineering or a related field, or by completing a training program offered by a technical school or community college.

What is the average salary for an Injection Mold Technician?

The average salary for an Injection Mold Technician is around $25,000 per year.

What are the benefits of working as an Injection Mold Technician?

The benefits of working as an Injection Mold Technician include job security, a competitive salary, and the opportunity to work in a fast-paced and challenging environment.